The simplest method to measure distances using pulsed waves is the “time-of-flight” method. The distance to an object is determined by measuring the time it takes for a laser pulse to travel to the target object and back to its origin after reflection. In general, this method lacks accuracy. Indeed, in order to accurately measure a difference in distances ranging between 1 and 10 micrometers with a normal laser, one would need to measure the time-of-flight difference at the femtosecond scale. Detectors with such time precision levels however do not exist and instruments using the time-of-flight method can not reach the micrometer accuracy level.

By contrast, Dr Kourogi et al. developed a time-of-flight technique that rely on the multiple lasing frequencies of OptoCombs to drastically improve this accuracy. Using two OptoCombs serving respectively as a reference and a probe, and knowing the phase difference between all teeth of the combs, it is possible to expand the time-scale needed to measure the time-of-flight difference by a factor 50,000. As a result the time needed to measure micrometer distances is not at the femtosecond level any more but orders of magnitude longer, at the nanosecond level. Such a time-scale is compatible with commercially available detectors and the intrinsic features of OptoCombs thus allow for measurements at the micrometer accuracy level.

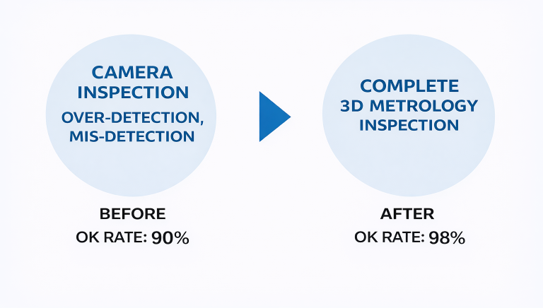

Effects

View more

Optcomb

View more

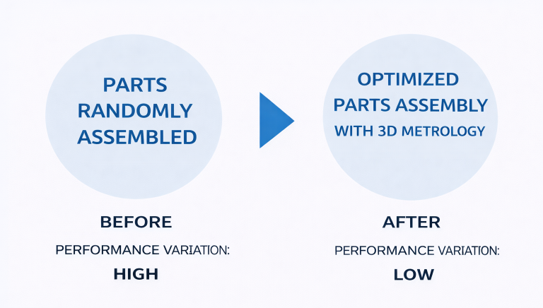

The optical frequency comb (OptoComb) is said to be the world’s most accurate ruler for the measurement of both frequency and time. It is a special type of laser made of sharp and evenly spaced spectral lines resembling the teeth of a comb. The OptoComb concept was discovered in 1993 by Dr Kourogi, currently Director and Honorary Fellow at XTIA. While pursuing his work as a leading researcher in optical comb technology, Dr Kourogi contributed to the research of John Hall and Theodor Hänsch, who were awarded the 2005 Nobel Prize in Physics, in which the development of the optical frequency comb played a major role. The OptoComb is a special kind of light that has the properties of both a monochromatic laser and polychromatic white-light. Therefore, it has the following characteristics:

・It contains light at many frequencies.

・The light of each frequency is a laser with a narrow spectral width

・The frequency intervals between each laser line are all the same

・The phase of each laser frequency is aligned.

In the time domain, the waveform of the OptoComb is a periodic train of sharp pulses with individual widths shorter than 1 picosecond, and an interval of several tens of picoseconds, as shown in the figure above. Dr Kourogi paid attention to these properties of the OptoComb and thought that if it could measure time with high precision, there was a possibility of applying it to high-precision distance measurement and 3D scanning.

advantages

View more

01

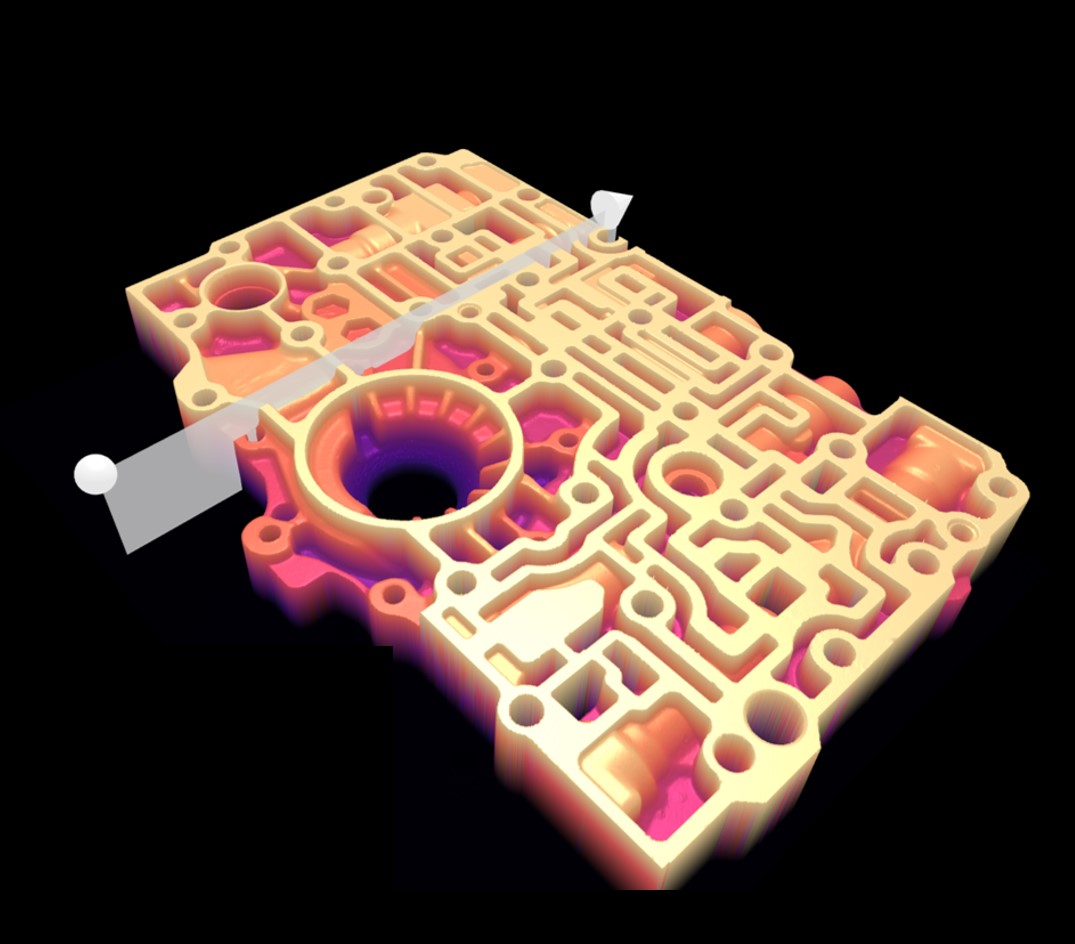

Thanks to their unique coaxial configuration, OptoComb 3D scanners by XTIA circumvent the shadowing effects that hinder traditional optical sensors. With their long working distance, OptoComb scanners can thus probe objects deep into holes and slits and provide the full 3D profile of the most complex parts: cylinder heads, valve bodies, rotors…

02

OptoComb 3D scanners can acquire up to 500,000 data points per second. This leads to a scanning process drastically faster than traditional contact measurement methods. Our scanners can thus meet short cycle time and they are routinely integrated in-line for the automated inspection of 100% of parts.

03

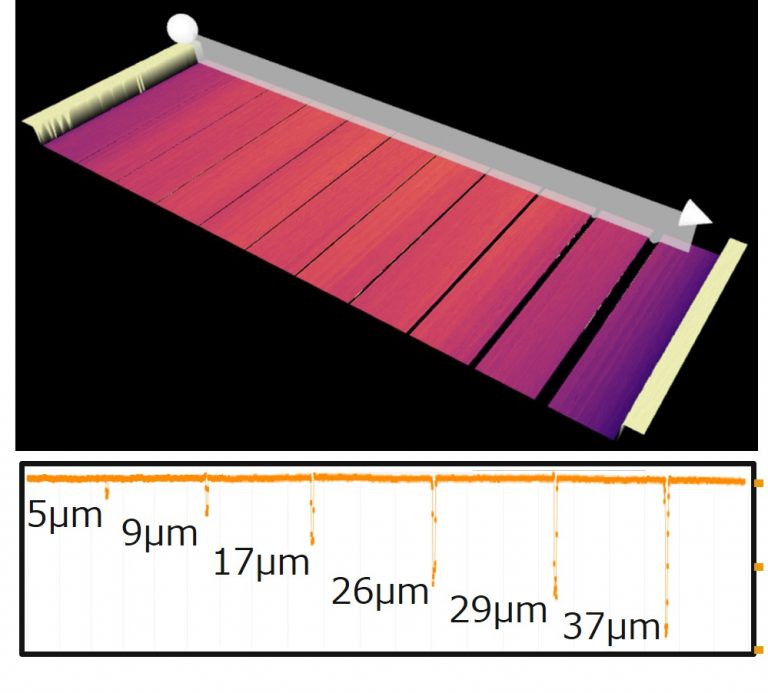

With their unique measurement scheme, OptoComb scanners can achieve such a performance while reaching a resolution as high as 1μm along the laser axis. This is of course essential for dimensional inspection, in a context where manufacturing processes are becoming more precise while design tolerance are getting tighter. Furthermore, it can be leveraged to optimize the visual inspection process. Unlike traditional contact inspection methods, OptoComb 3D scanners can detect and provide quantitative information on a large range of 3D microdefects such as dents, scratches, particles, burrs and more.

04

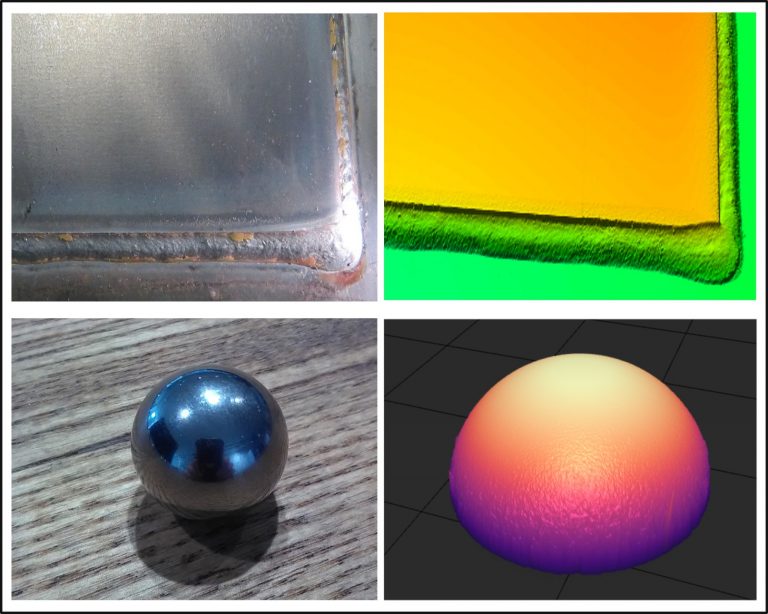

Furthermore, as opposed to a lot of optical sensors out there, the interferential detection scheme of OptoComb 3D scanners prevents the system from being affected by the ambient light. They are thus the ideal solution for the inspection of both matt and shiny parts on the manufacturing floor whatever the light environment.

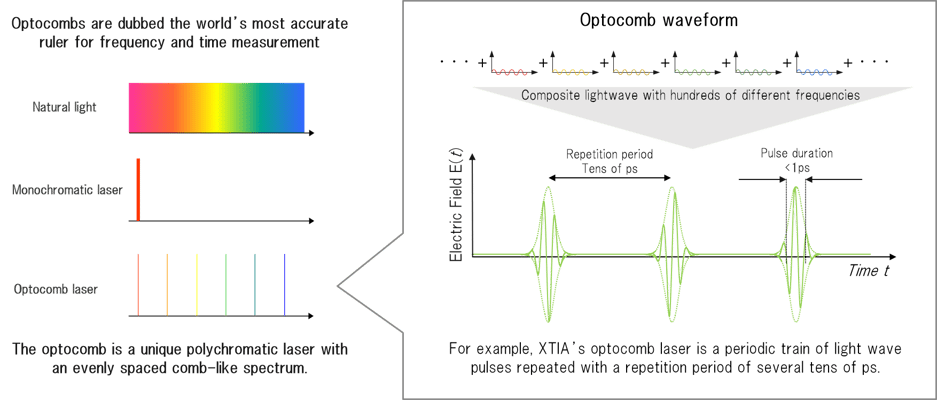

Applications

View more

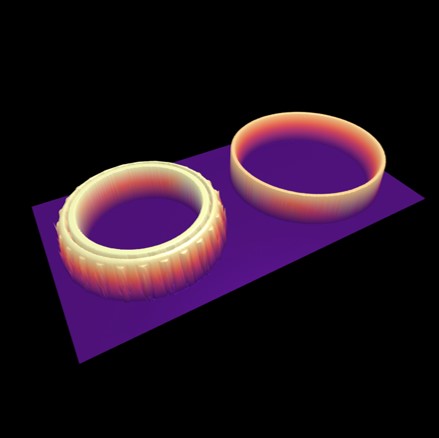

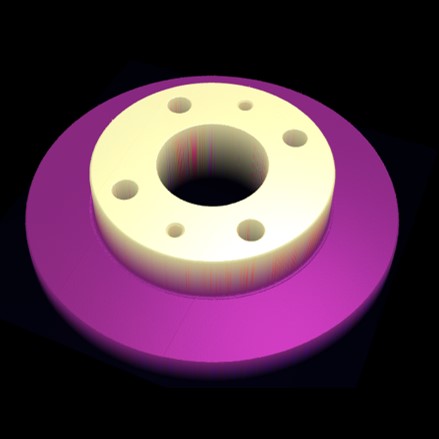

Automating the quality control of complex parts such as bearings can be a difficult task for manufacturers because traditional methods are either slow or only provide a partial profile. With their coaxial configuration and long working distance, OptoComb 3D scanners circumvent such difficulties and scan the smallest features and defects of the bearing. By integrating the OptoComb 3D scanners in-line, manufacturers can also leverage the high sampling rate of our 3D scanners to perform the inspection of 100% of manufactured bearings.

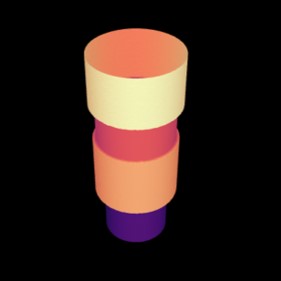

Many medium and large parts have cylindrical features that need to meet high quality requirements and the ever-demanding designs of modern manufacturing. To tackle this issue, we have leveraged the coaxial configuration of our OptoComb 3D scanners to offer custom soutions dedicated to the inspection of bores. By combining our OptoComb 3D scanner with a rotating mirror that translates within the structure along its rotating axis, we can probe the inner walls of bores and extract their 3D profile.

Manufacturers need fast and precise solutions to meet the ever-demanding designs and the fast pace of modern manufacturing. This is especially true for brake disk rotors that are subject to tight tolerances and short inspection times. With their unique coaxial configuration, OptoComb scanners go beyond traditional sensors and can provide a full 3D profile of brake disks with high accuracy. By integrating OptoComb 3D scanners in-line and leveraging their 500,000points/sec acquisition rate, manufacturers can fully automate the inspection of 100% of parts.

Engineering is a world where quantitative judgment should and can be made, but this has often been difficult to achieve on a manufacturing floor dominated by human inspection. With the automated inspection solutions offered, quantitative inspection and engineering of micrometer defects is finally possible: OptoComb 3D scanners have a reliable track record for the detection of a large range of 3D defects such as dents, scratches, particles, burrs and more.

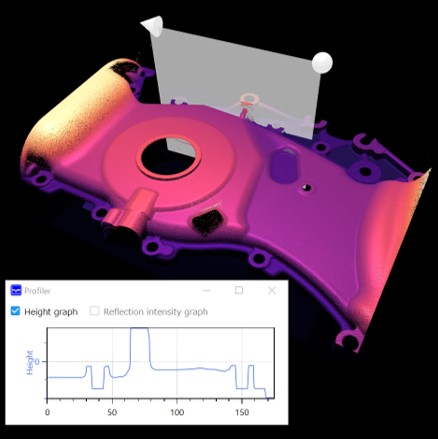

Conrods can be measured by our L90 OptoComb sensor, a 3D scanner presenting a 10 micrometer resolution along the laser axis, and a 100 micrometer resolution in the XY plane. You can visualize the conrod in 3D, explore the part point by point or with 2D cross-sections, and assess positions, dimensions, and distances with high accuracy. Our OptoComb Suite can also automate the inspection process, perform the GD&T analysis, assess the conrod features, and give instant access to the part's tolerances.

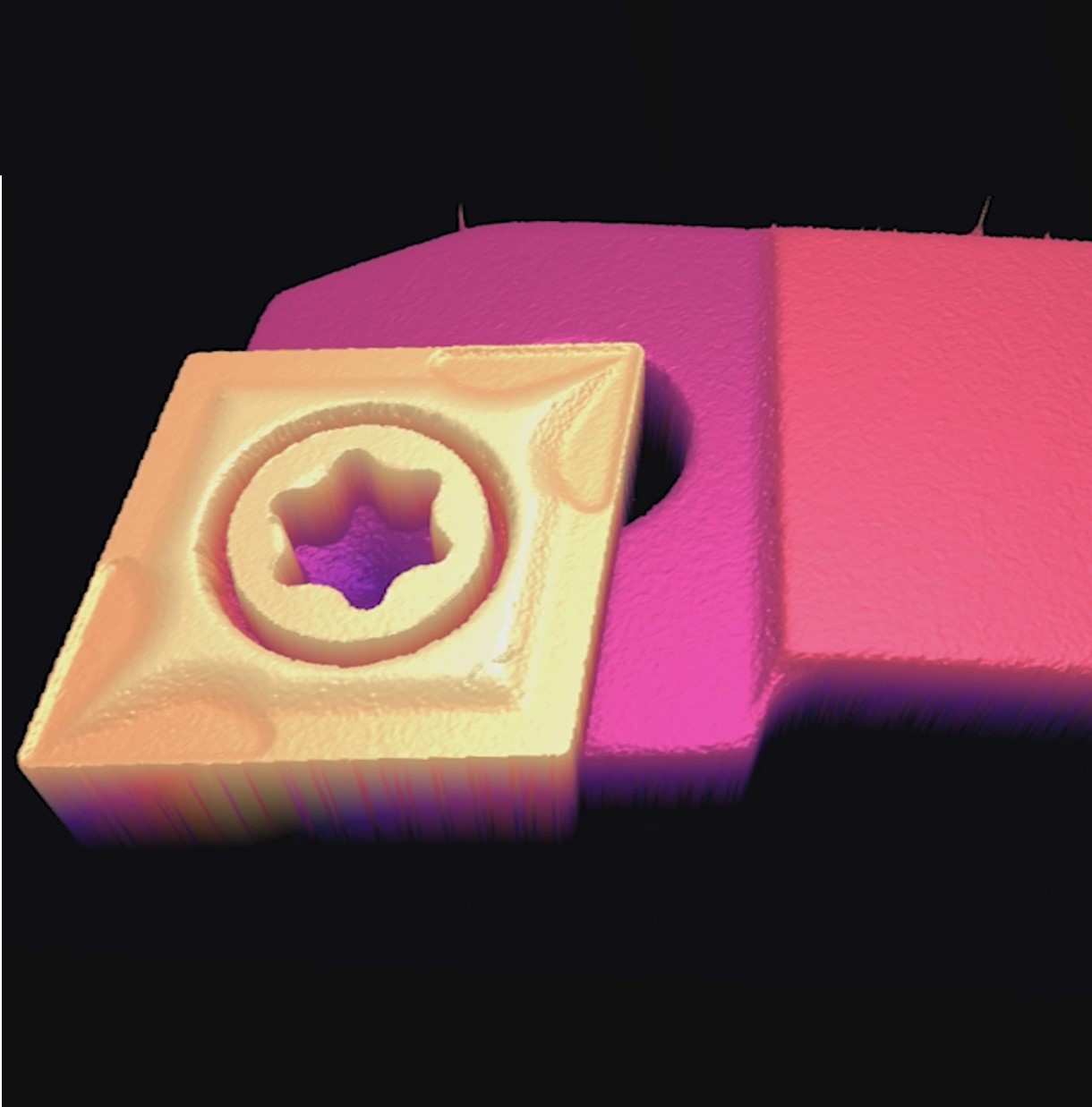

Machine tools are at the heart of today's production processes and are subject to tighter and tighter tolerances. With their 500kHz acquisition rate and 1μm resolution, OptoComb 3D scanners are ideal to meet manufacturer's challenges and streamline their manufacturing process. In seconds, you can obtain a high-accuracy scan of your tools insert, detect the presence of microdefects and instantly assess the insert dimensions and positioning.

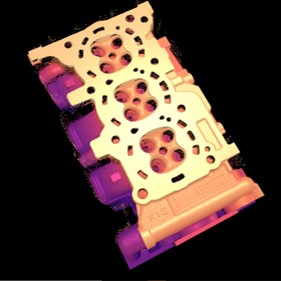

With our unique OptoComb 3D scanners based on Optical Frequency Comb technology, you can fully profile your cylinder head with microscale accuracy, enabling both dimensional and visual inspection in a single scan. OptoComb 3D scanners can measure 500,000 points per seconds and can complete a full cylinder head scan with a fine pitch in a few tens of seconds. It is significantly faster than traditional contact CMM inspection methods, but it is also more flexible and user-friendly as no measurement recipe is needed.

Our coaxial laser systems that scan objects and give access to the full 3D profile of parts with high accuracy. With this Nobel-winning technology, OptoComb 3D scanners are capable of measuring 500,000 data points per second, a high-speed performance that significantly shortens the time to scan manufactured parts. As a result, they are the ideal solution for a fully automated dimensional inspection of complex structures such as cast, forged, and machined parts.

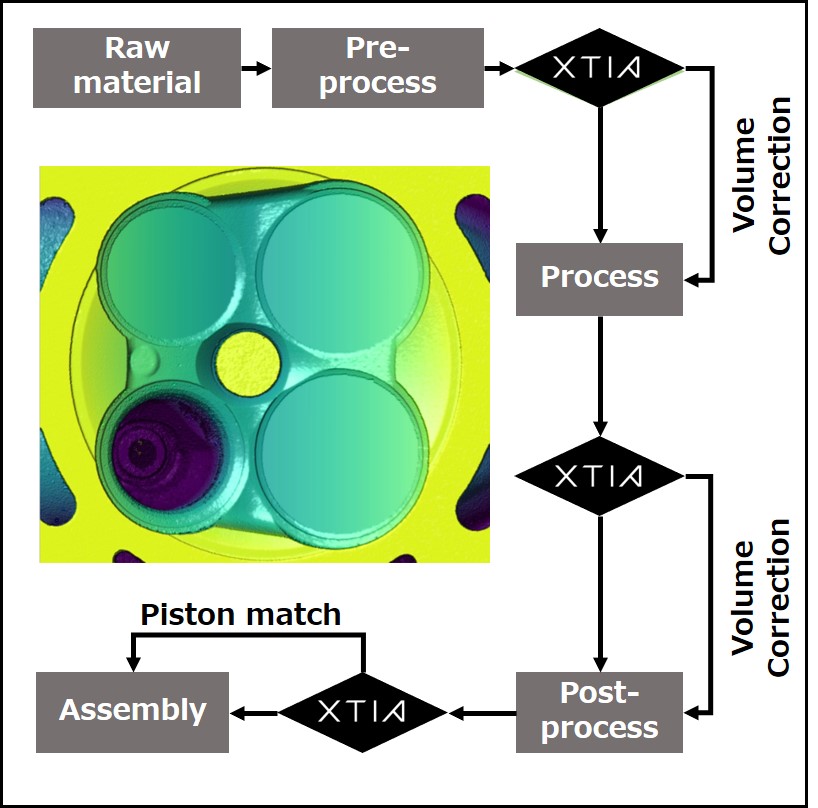

Nowadays, the quest for higher performance and aggressive designs in all manufactured products has led to one of the biggest challenges in product design and manufacturing: how to reduce this variation. The OptoComb technology and our coaxial laser scanners provide access to the dimensional profile of complex structures with high accuracy. As a result, our solutions can be extremely valuable if integrated within the manufacturing process flow, because it opens the door to the reduction of geometric tolerances by a specific correction process.

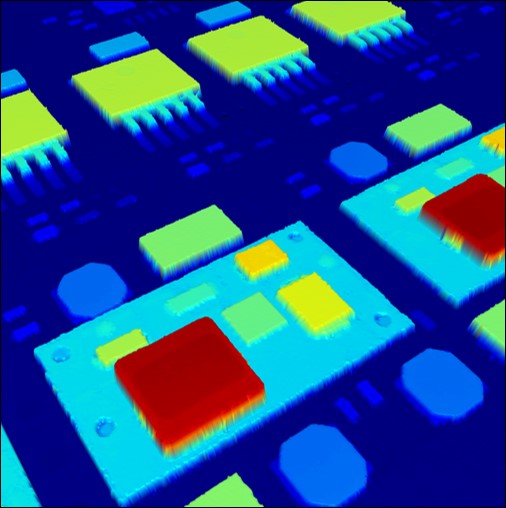

With their 1 μm resolution and 500 kHz acquisition speed, OptoComb 3D scanners go beyond the limits of conventional 2D inspection methods. They can measure in seconds the full 3D profile of printed circuit boards, including the smallest and most complex 3D features. Based on the high-accuracy 3D data of OptoComb, the automated inspection solutions offered by us provide an instant assessment of the PCB dimensions and the 3D positioning of surface-mount devices. In addition, it also allows for the automated recognition of 3D microdefects.

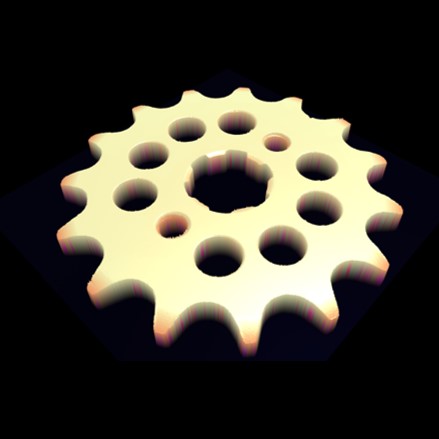

With the high quality requirements and the ever-demanding designs of modern fabrication, manufacturers need fast and precise solutions for the quality control of all their manufactured parts. This is especially true for sprockets that is subject to tight tolerances. With OptoComb 3D scanners, manufacturers can measure at a 500,000points/sec rate and fully profile their sprocket with a 1μm resolution. By integrating OptoComb 3D scanners in-line, manufacturers can thus fully automate the inspection of all manufactured sprockets.

Automating the inspection process of complex parts such as valve bodies can be a difficult task for manufacturers because traditional methods are either slow or do not provide access to the full 3D profile. With their coaxial configuration and long working distance, OptoComb 3D scanners circumvent such difficulties and can give access to the smallest features and defects of a valve body. Manufacturers can also leverage the 500,000 points/sec scanning rate of our 3D scanners to fully automate the quality control of their valve body.

Superiority

View more