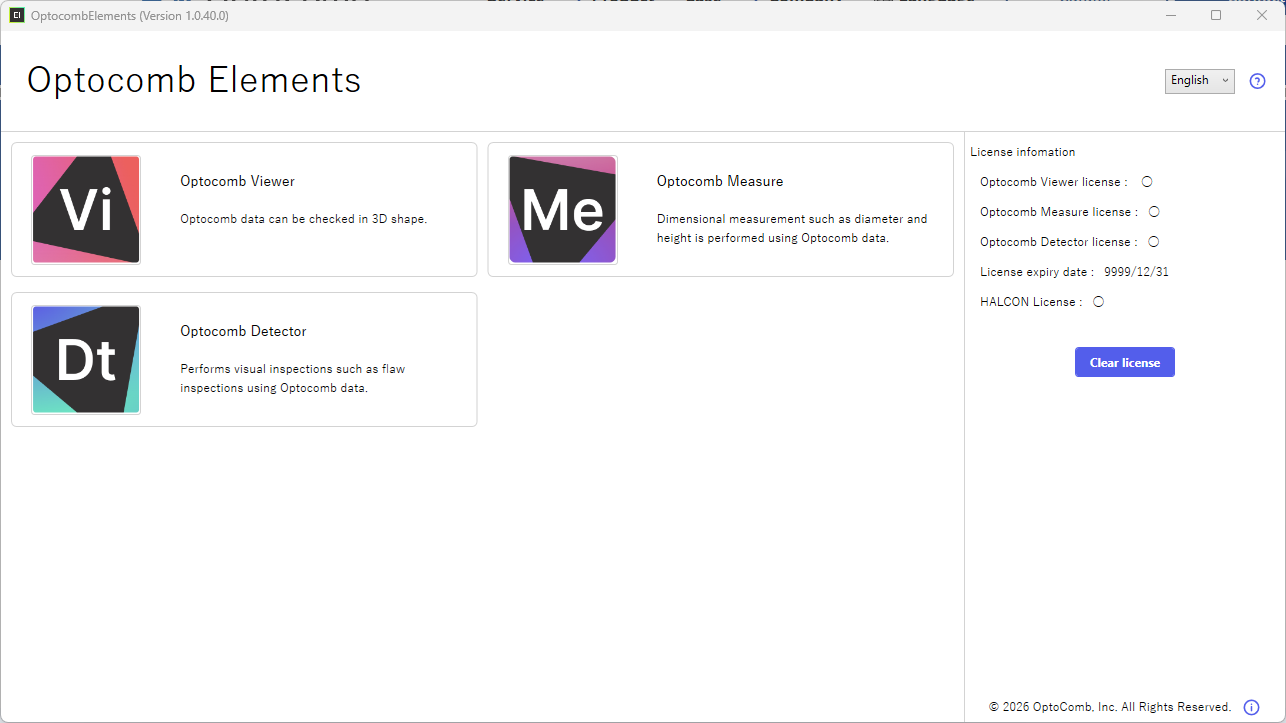

Software

View more

View more

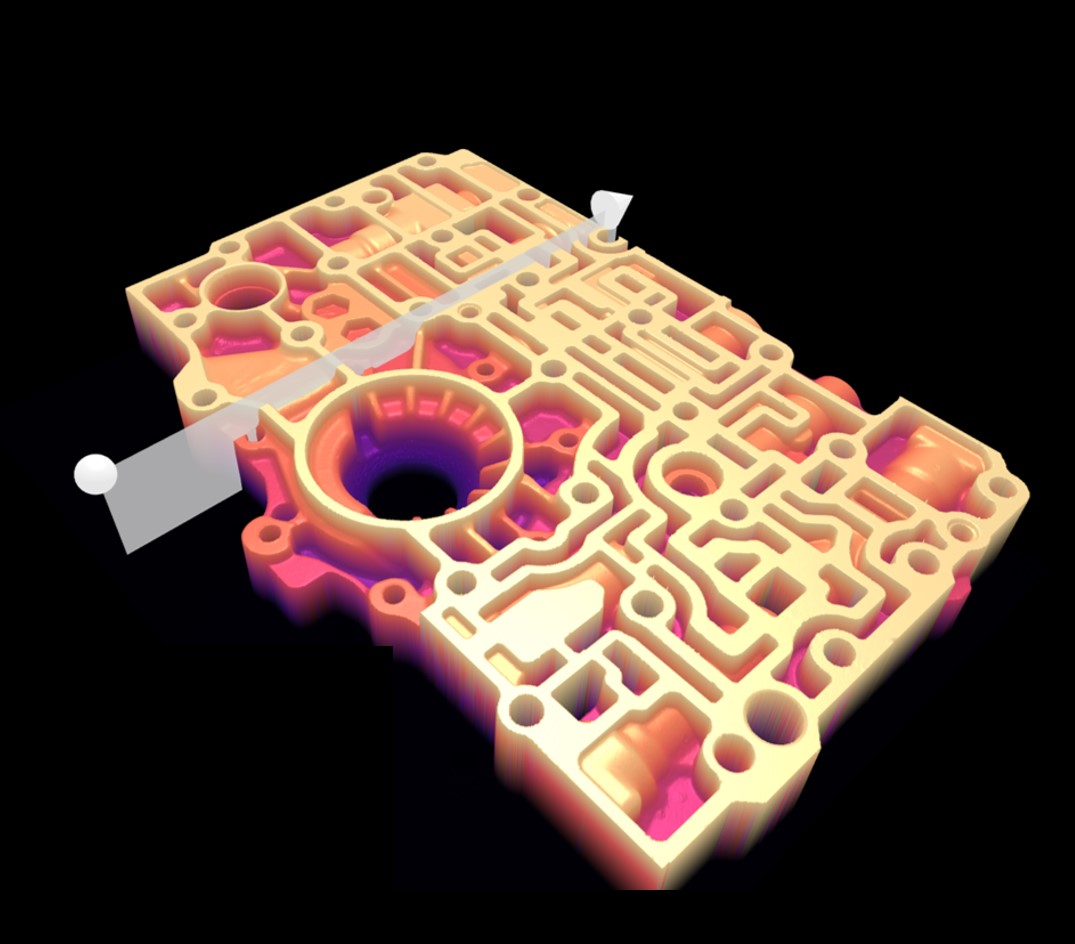

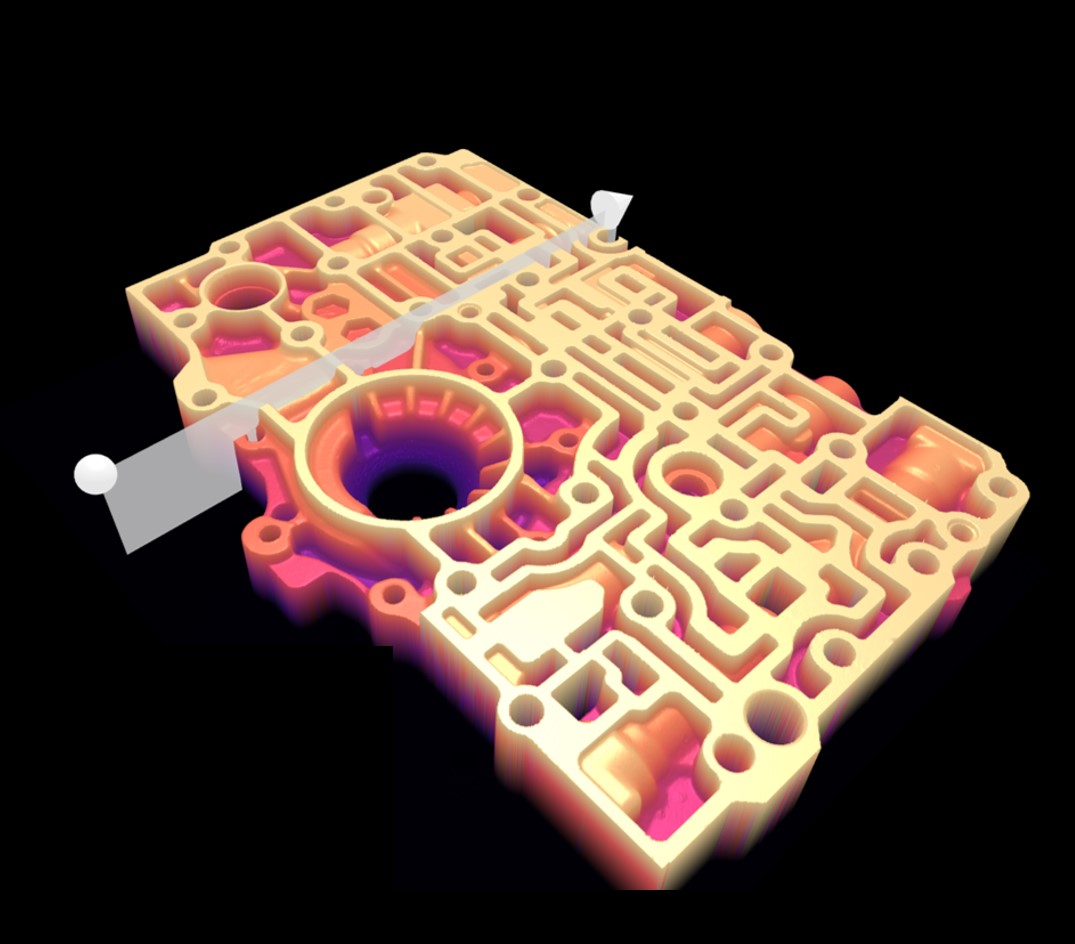

With OptoComb Viewer, you can visualize and explore the high-resolution data of your OptoComb scanner. You can probe the smallest features and assess positions, diameters, dimensions and distances with high accuracy. OptoComb Viewer can also fit your 3D data with various geometries to gain even further insight into your part's 3D profile.

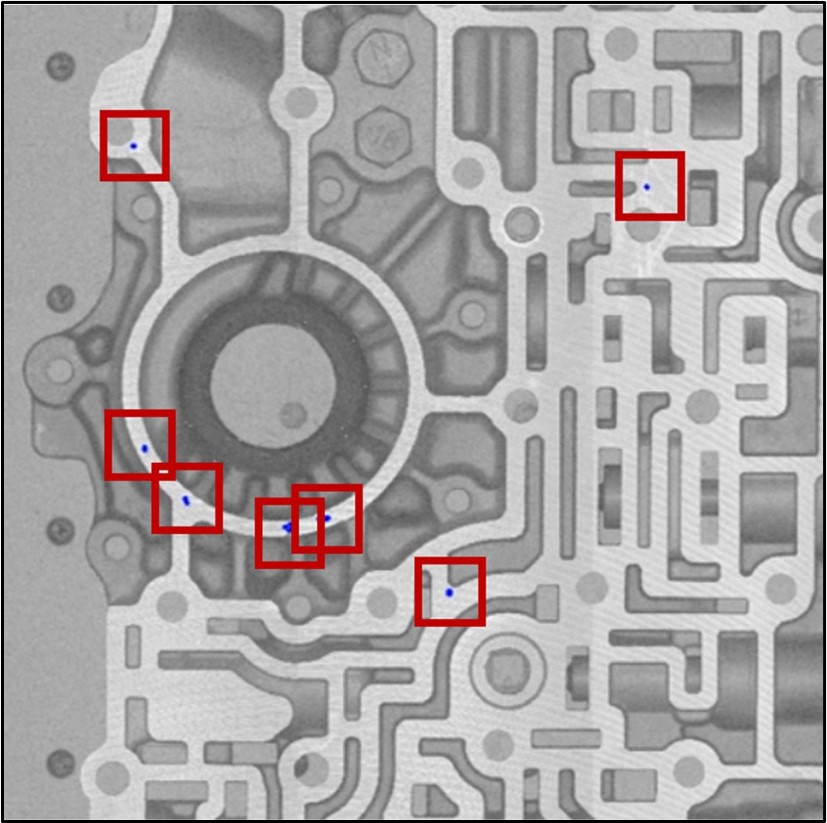

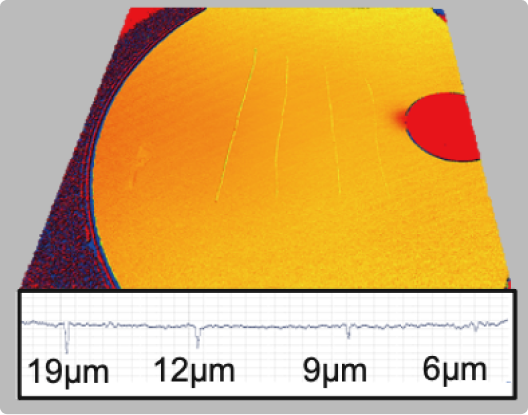

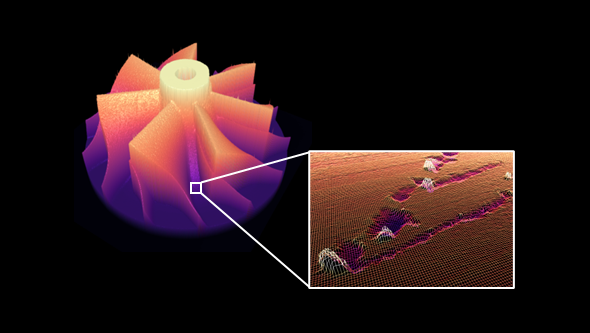

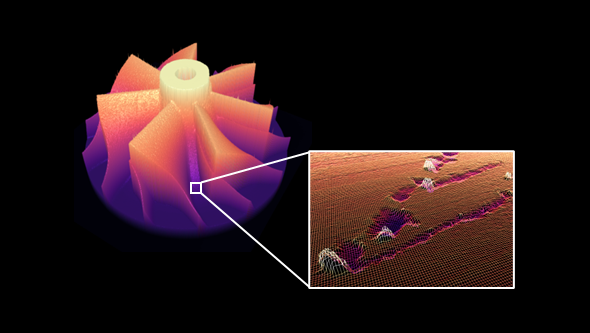

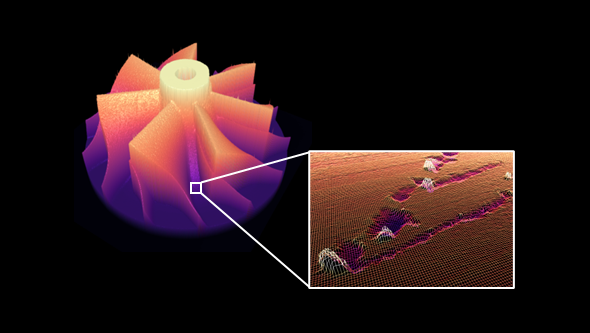

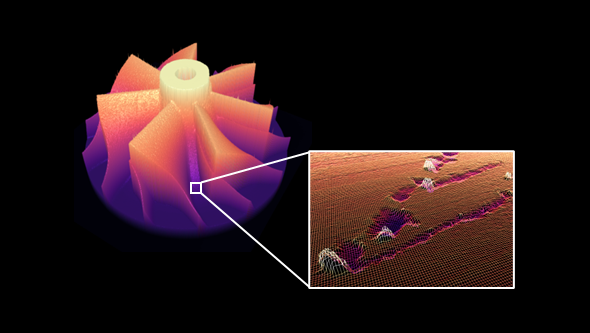

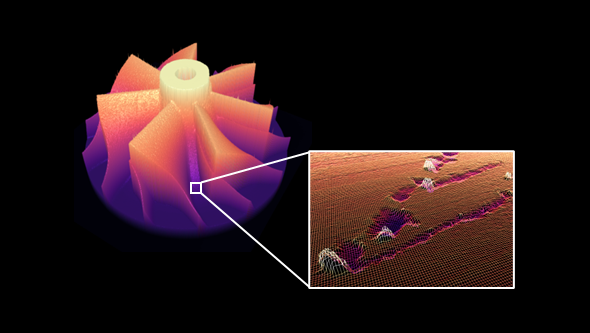

A major advantage of XTIA's OptoComb 3D scanners is their micrometer resolution enabling the measurement of 3D microdefects such as burrs and scratches. The OptoComb Detector toolbox makes the most of this high-resolution data and offers unique algorithms and custom recipes dedicated to the automated detection, identification and quantification of 3D microdefects. OptoComb Detector is integrated with the 3D scanning process and enables a fully automated visual inspection from data acquisition to data analysis and inspection report generation. OptoComb Detector is thus an all-in-one toolbox for all visual inspection purposes.

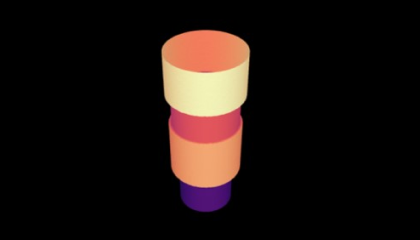

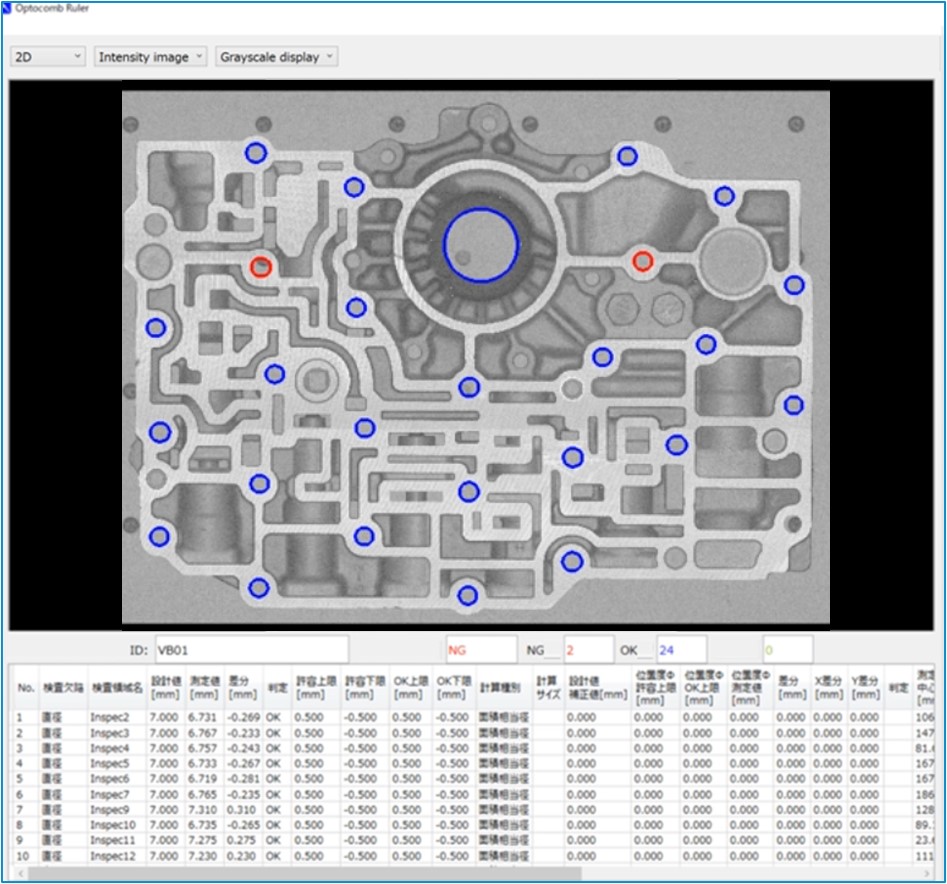

Dimension analysis is performed from 3D point cloud data obtained with an optical comb sensor. For example, we use dimensional analysis functions to automatically inspect specified locations, such as hole diameter, hole position, and distance from the datum.

- Creation of dimensional inspection recipe

- Analysis of dimensional information and creation of inspection reports

Applications

View more

加工部品は常にバリとの闘いとなります。その工法の性質上、バリを完全になくすことは難しい一方で、高さ方向のある欠陥であるバリは重要機能障害を起こすケースも多くあ

加工部品は常にバリとの闘いとなります。その工法の性質上、バリを完全になくすことは難しい一方で、高さ方向のある欠陥であるバリは重要機能障害を起こすケースも多くあります。しかし、バリは小さくまた、高さ方向があるため、その検出方法は非常に難しく、バリをどうやって次工程に流さないかはとても難しい製造の課題となっています。

加工部品は常にバリとの闘いとなります。その工法の性質上、バリを完全になくすことは難しい一方で、高さ方向のある欠陥であるバリは重要機能障害を起こすケースも多くあります。しかし、バリは小さくまた、高さ方向があるため、その検出方法は非常に難しく、バリをどうやって次工程に流さないかはとても難しい製造の課題となっています。

加工部品は常にバリとの闘いとなります。その工法の性質上、バリを完全になくすことは難しい一方で、高さ方向のある欠陥であるバリは重要機能障害を起こすケースも多くあります。しかし、バリは小さくまた、高さ方向があるため、その検出方法は非常に難しく、バリをどうやって次工程に流さないかはとても難しい製造の課題となっています。

加工部品は常にバリとの闘いとなります。その工法の性質上、バリを完全になくすことは難しい一方で、高さ方向のある欠陥であるバリは重要機能障害を起こすケースも多くあります。しかし、バリは小さくまた、高さ方向があるため、その検出方法は非常に難しく、バリをどうやって次工程に流さないかはとても難しい製造の課題となっています。

View more

View more

OptoComb 3D scanners by XTIA can access the profile of the most complex manufactured parts. The OptoComb Ruler toolbox leverages this 3D data to offer a GD&T analysis based on the part's design. OptoComb Ruler offers a user-friendly environment to fully customize and automate your dimensional inspection process from data acquisition to GD&T analysis and inspection report generation. OptoComb Ruler is thus the ideal toolbox for both the seasoned metrologist and the dimensional inspection operator.

Main Functions

・Dimensional inspection

・Automated GD&T analysis

・Custom recipes

不明

Main Functions

不明

不明

Main Functions

不明

不明

Main Functions

不明

不明

Main Functions

不明