Software

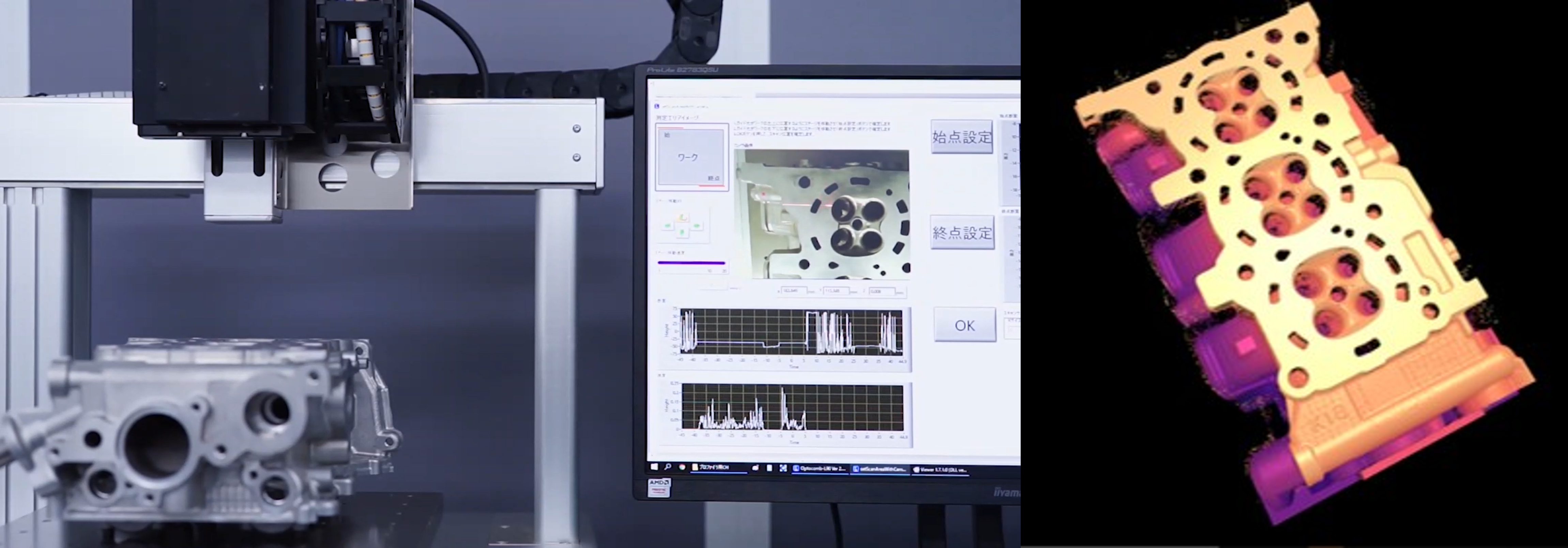

A software designed for the acquisition of optical comb 3D point cloud data.

The software enables area and line scanning with easily tunable pitch value, making the optimization of measurement condition hassle-free.

The automation of measurement to data extraction in various format can be carried out seamlessly, all you need to do is press that start button.

View more

The software offers 2 different types of scanning method to optimize the 3D data measurement depending on the size of your workpiece.

The line scan method allows for the expanded mobility in Y axis direction, hence it is recommended for a broader work size. However it is to be noted that the measurement precision for line scan method will be compromised to the precision of the mounting stage.

On the other hand the area scan method allows for the measurement to be carried out while the work is fixed to the stage (with no movement in XY direction). For this reason, the high precision of the 3D measurement can be maintained. This scanning method is highly recommended in case where high precision inspection is required.

▼XY axis measurement pitch

The resolution of 3D measurement can is determined by the the density of measurement points (distance between measurement points) . High density data points will result in higher data resolution and vice versa. This will also impact the scanning time. The scan software allows you to easily tune the measurement parameter to suit your measurement needs with ease.

▼Focal point adjustment (Z-axis)

Focus adjustment is a necessary step for any optical measurement instrument. With our software, the focus adjustment can be carried out seamlessly with the assistance of built-in monitoring interface fetures.

The output data format can be selected in binary, CSV, and STL. Our optical comb 3D data inspection and analysis software, OptoComb Elements works on binary format data.

Applications

View more

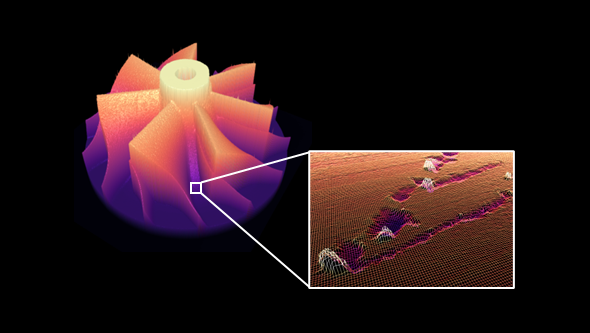

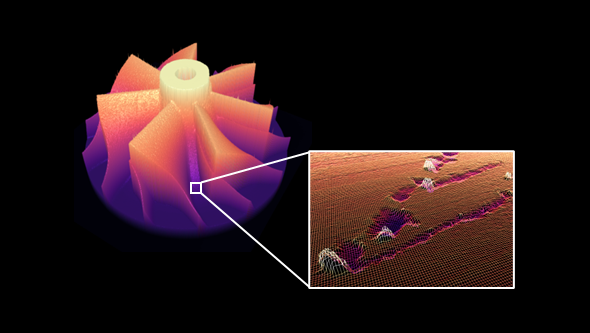

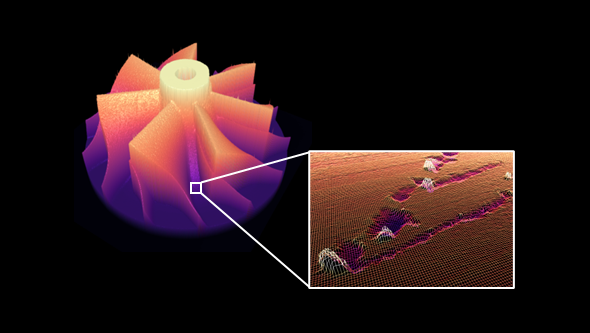

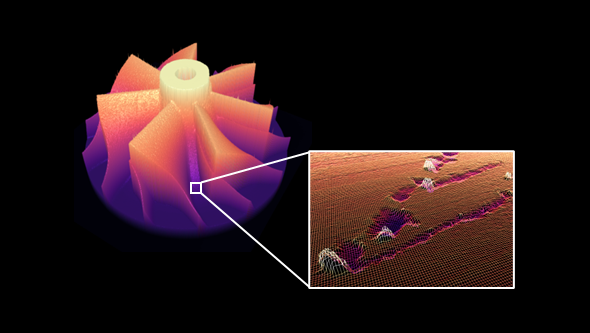

加工部品は常にバリとの闘いとなります。その工法の性質上、バリを完全になくすことは難しい一方で、高さ方向のある欠陥であるバリは重要機能障害を起こすケースも多くあ

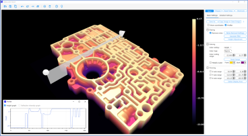

加工部品は常にバリとの闘いとなります。その工法の性質上、バリを完全になくすことは難しい一方で、高さ方向のある欠陥であるバリは重要機能障害を起こすケースも多くあります。しかし、バリは小さくまた、高さ方向があるため、その検出方法は非常に難しく、バリをどうやって次工程に流さないかはとても難しい製造の課題となっています。

加工部品は常にバリとの闘いとなります。その工法の性質上、バリを完全になくすことは難しい一方で、高さ方向のある欠陥であるバリは重要機能障害を起こすケースも多くあります。しかし、バリは小さくまた、高さ方向があるため、その検出方法は非常に難しく、バリをどうやって次工程に流さないかはとても難しい製造の課題となっています。

加工部品は常にバリとの闘いとなります。その工法の性質上、バリを完全になくすことは難しい一方で、高さ方向のある欠陥であるバリは重要機能障害を起こすケースも多くあります。しかし、バリは小さくまた、高さ方向があるため、その検出方法は非常に難しく、バリをどうやって次工程に流さないかはとても難しい製造の課題となっています。

加工部品は常にバリとの闘いとなります。その工法の性質上、バリを完全になくすことは難しい一方で、高さ方向のある欠陥であるバリは重要機能障害を起こすケースも多くあります。しかし、バリは小さくまた、高さ方向があるため、その検出方法は非常に難しく、バリをどうやって次工程に流さないかはとても難しい製造の課題となっています。

View more

不明

Main Functions

・Optcomb Viewer

・Optcomb Detector

・Optcomb Measure

OptoComb 3D scanners by XTIA can access the profile of the most complex manufactured parts. The OptoComb Ruler toolbox leverages this 3D data to offer a GD&T analysis based on the part's design. OptoComb Ruler offers a user-friendly environment to fully customize and automate your dimensional inspection process from data acquisition to GD&T analysis and inspection report generation. OptoComb Ruler is thus the ideal toolbox for both the seasoned metrologist and the dimensional inspection operator.

Main Functions

・Dimensional inspection

・Automated GD&T analysis

・Custom recipes

不明

Main Functions

不明

不明

Main Functions

不明

不明

Main Functions

不明