HARDWARE

View more

View more

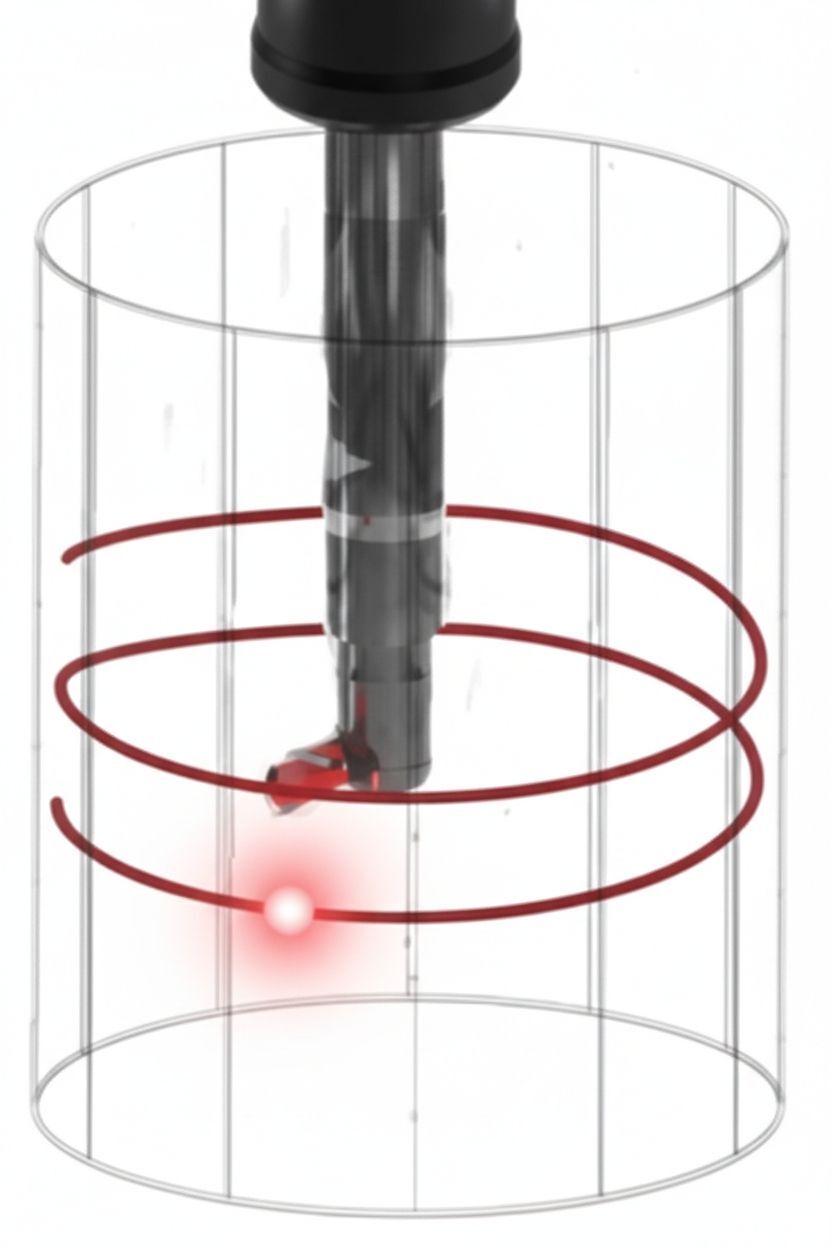

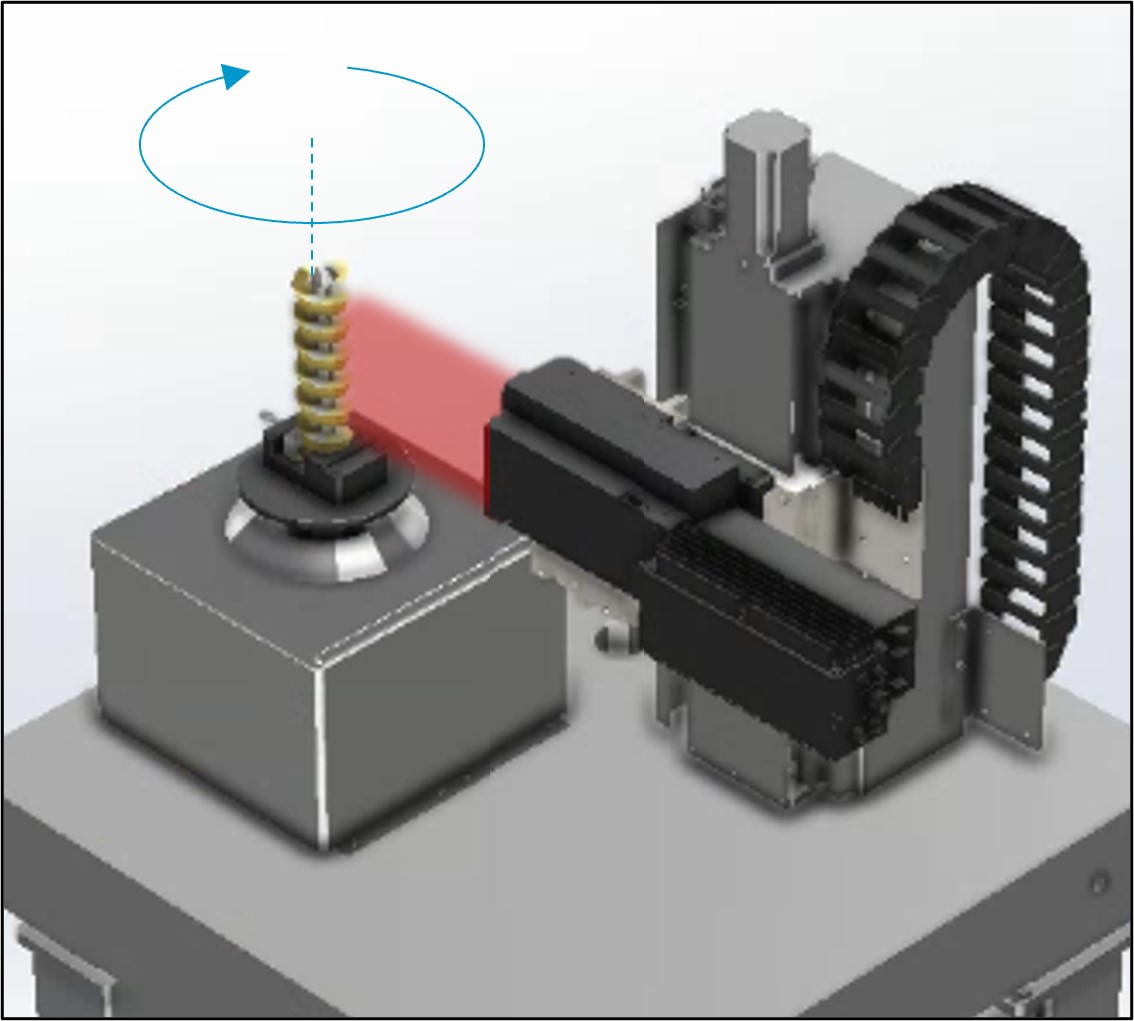

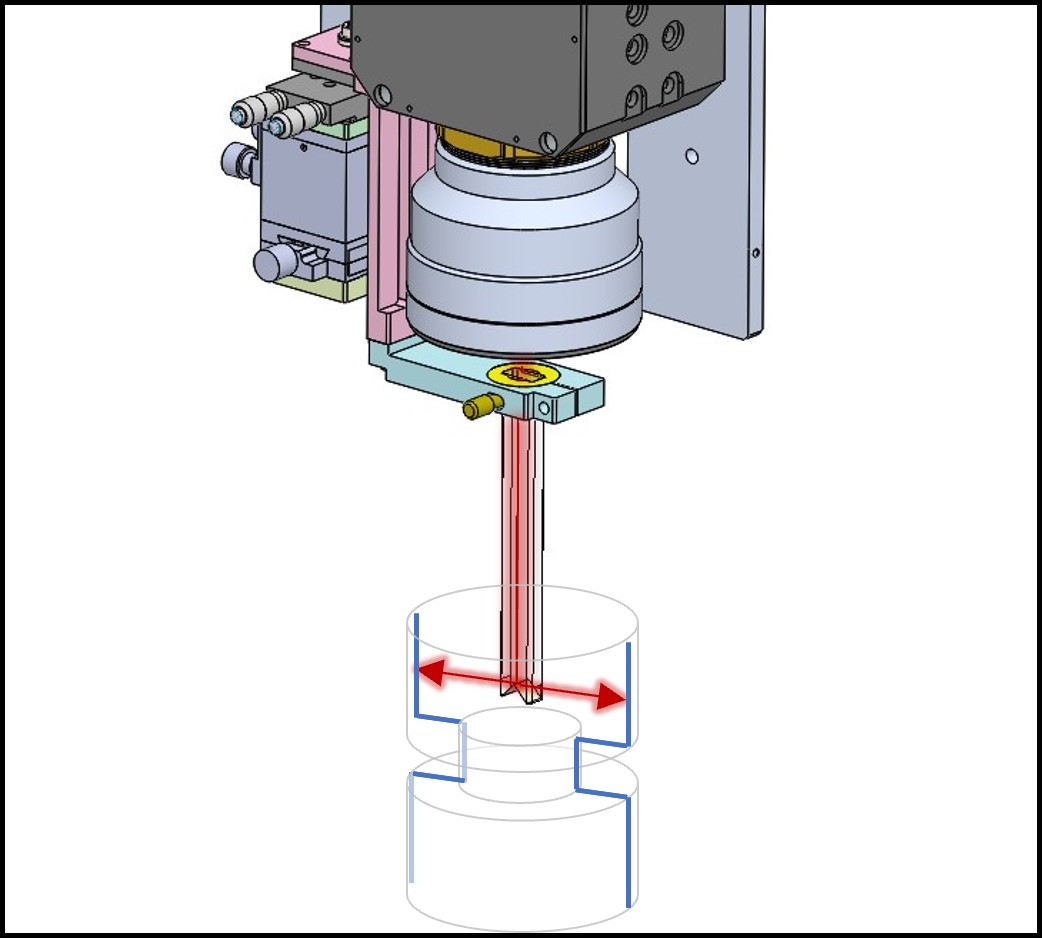

The laser is reflected by a 90° mirror and projected onto the inner surface of the cylinder. The three-dimensional shape of the inner surface of a cylinder can be measured with high precision by rotating and raising the spindle with a mirror.

Applications

View more

加工部品は常にバリとの闘いとなります。その工法の性質上、バリを完全になくすことは難しい一方で、高さ方向のある欠陥であるバリは重要機能障害を起こすケースも多くあ

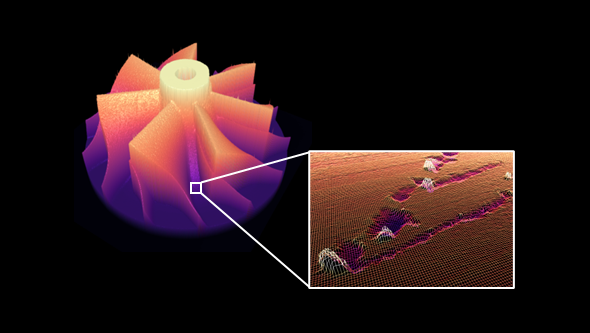

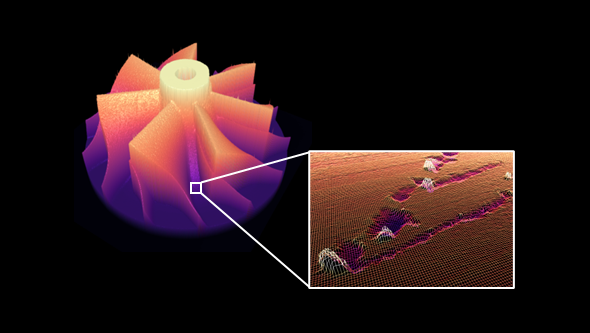

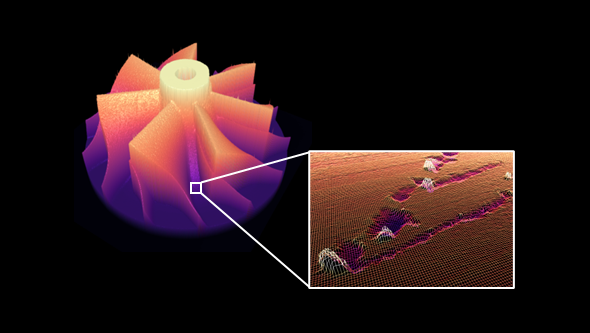

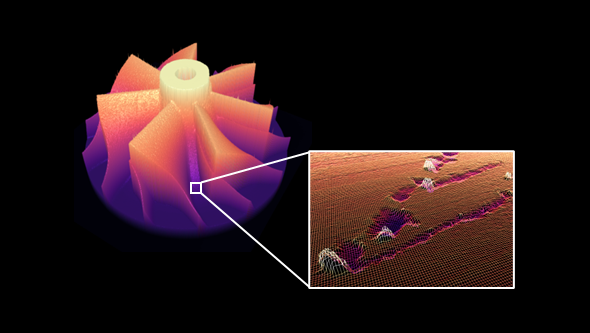

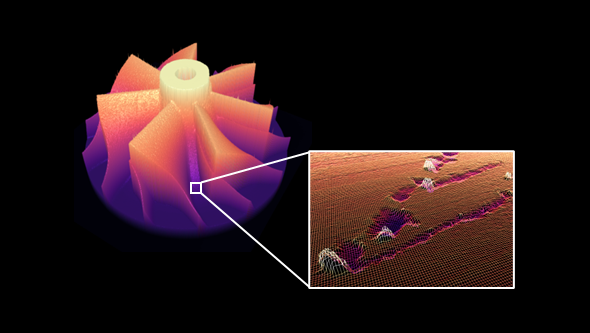

加工部品は常にバリとの闘いとなります。その工法の性質上、バリを完全になくすことは難しい一方で、高さ方向のある欠陥であるバリは重要機能障害を起こすケースも多くあります。しかし、バリは小さくまた、高さ方向があるため、その検出方法は非常に難しく、バリをどうやって次工程に流さないかはとても難しい製造の課題となっています。

加工部品は常にバリとの闘いとなります。その工法の性質上、バリを完全になくすことは難しい一方で、高さ方向のある欠陥であるバリは重要機能障害を起こすケースも多くあります。しかし、バリは小さくまた、高さ方向があるため、その検出方法は非常に難しく、バリをどうやって次工程に流さないかはとても難しい製造の課題となっています。

加工部品は常にバリとの闘いとなります。その工法の性質上、バリを完全になくすことは難しい一方で、高さ方向のある欠陥であるバリは重要機能障害を起こすケースも多くあります。しかし、バリは小さくまた、高さ方向があるため、その検出方法は非常に難しく、バリをどうやって次工程に流さないかはとても難しい製造の課題となっています。

加工部品は常にバリとの闘いとなります。その工法の性質上、バリを完全になくすことは難しい一方で、高さ方向のある欠陥であるバリは重要機能障害を起こすケースも多くあります。しかし、バリは小さくまた、高さ方向があるため、その検出方法は非常に難しく、バリをどうやって次工程に流さないかはとても難しい製造の課題となっています。

View more

ダダミーテキストミーテキストダミーテキストダミーテキストダミーテキストダミーテキストダミーテキストダミーテキスト

View more

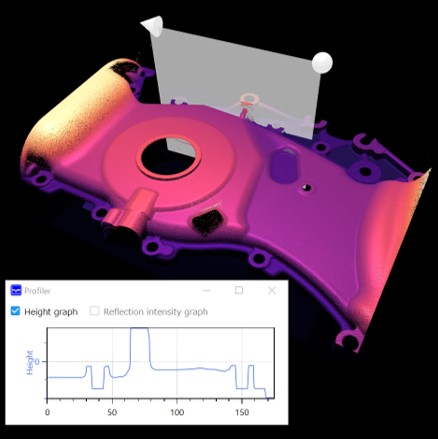

Optocomb 3D scanners by XTIA are the first industrial application of the Nobel-prize winning Optocomb technology. With their coaxial configuration, their long working distance, their 500kHZ rate and a resolution as high as 1μm, OptoComb scanners are the ideal 3D scanning solution for a fully automated quality control. OptoComb scanners have a reliable track record for the GD&T of your most complex parts and for the detection of a large range of 3D defects such as dents, scratches, particles, burrs and more.

不明

不明

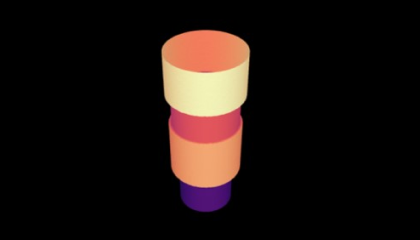

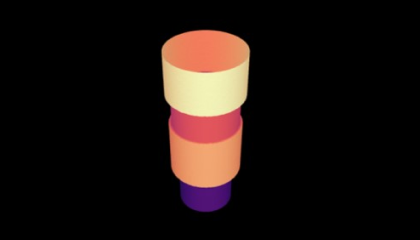

OptoComb 360 is a unique inspection system combining an OptoComb 3D scanner with a rotating stage to scan objects over 360°. With this system, XTIA brings a new visual and dimensional inspection solution to the table and enables the outer surface of spools and other structures with rotational symmetry to be measured with high accuracy.

Leveraging their unique coaxial configuration and high accuracy, OptoComb 3D scanners can be combined with a 45° mirror to successfully inspect the inner walls of bores and complex cylindrical structures in seconds.

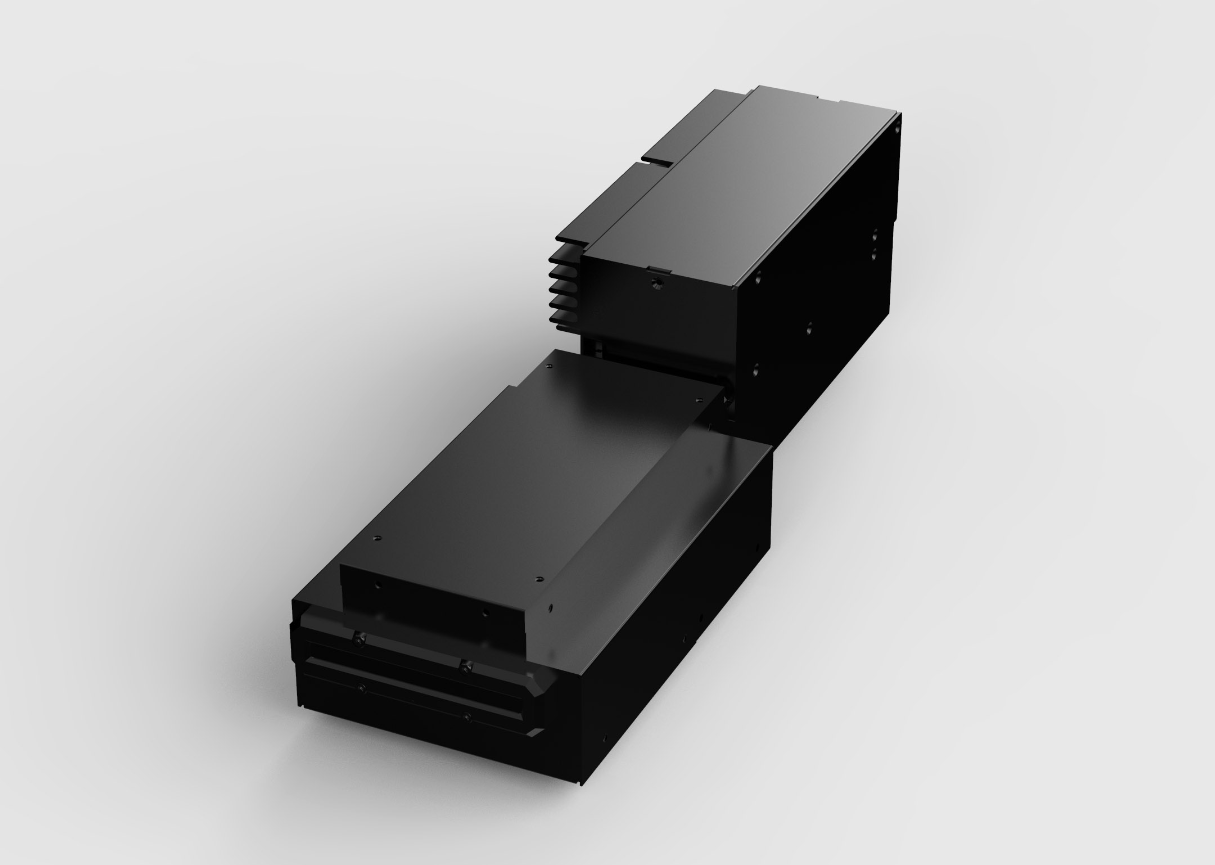

In collaboration with its partner JUKI, XTIA offers its Hybrid solution: a fully automated system integrating both a 12 Megapixel optical camera and a high-resolution S40 OptoComb 3D scanner. The system maximizes resolution in all three directions for an optimal visual inspection and defect detection process. By taking advantage of the very high speed of the optical camera, our hybrid system can reduce the cycle time of the overall automated inspection process.

不明

不明

不明