Check out what OptcoComb solutions has to offer

With OptoComb 3D sensor solutions line-up, we are confident to present to you high-precision, automated inspection system that will satisfy your measurement need.

All you need to know about Optocomb's solutions and their impact on manufacturing

With OptoComb 3D sensor solutions line-up, we are confident to present to you high-precision, automated inspection system that will satisfy your measurement need.

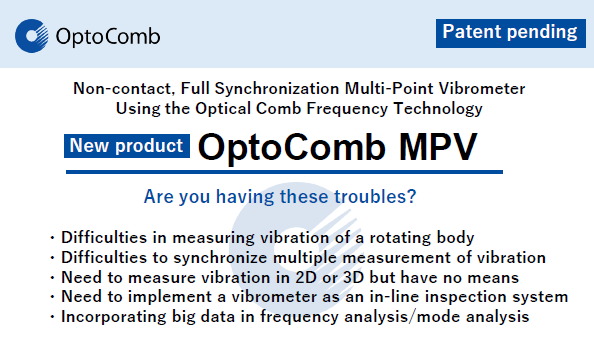

OptoComb MPV by OptoComb introduces a multi-point vibrometer that enables non-contact, fully synchronized, multi-point vibration measurement and analysis

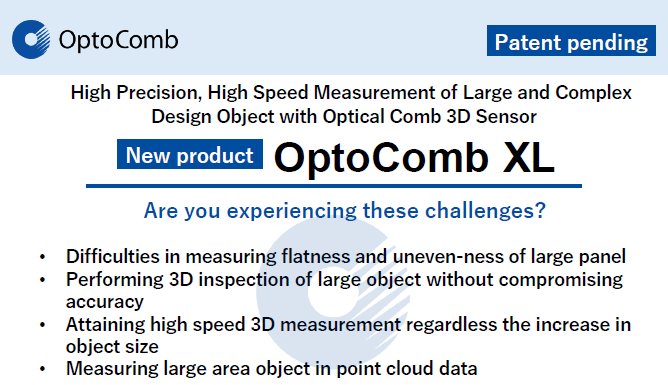

High speed 3D measurement and inspection of extra-large workpiece, enable measurment of object size from 470~2000mm in width to be performed in one scan.

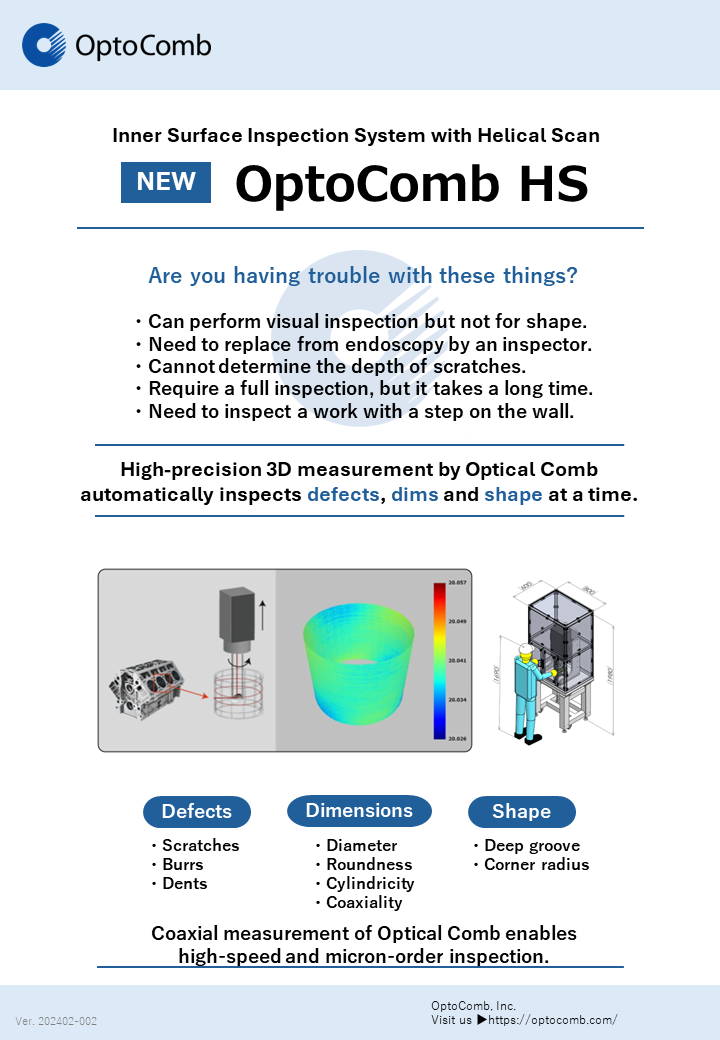

Inner surface Inspection System with Helical Scan

High-precision 3D measurement by Optical Comb automatically inspects defects, dims and shape of cyludical surface at a time.

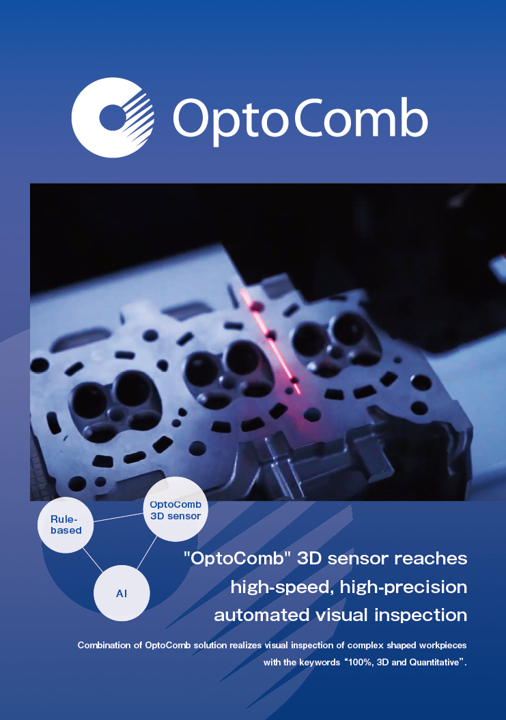

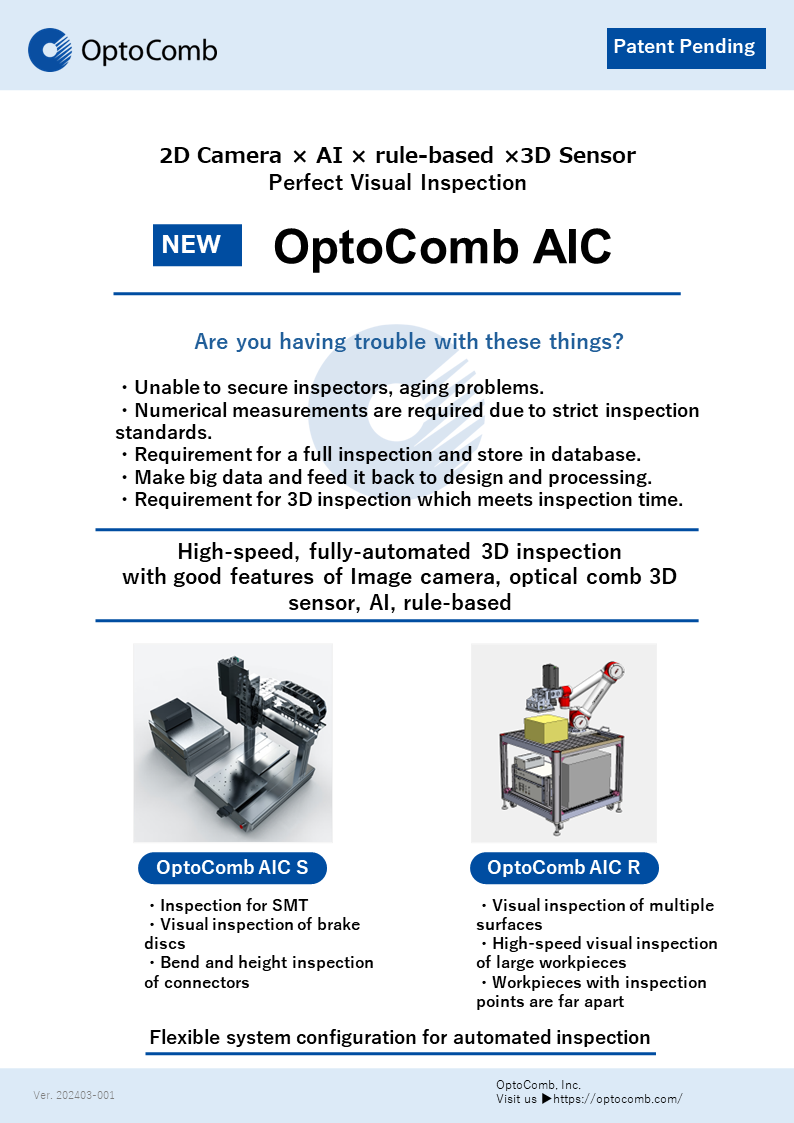

2D Camera x AI x rule-based x 3D Sensor

High-speed, fuly automated 3D inspection by OptoComb AIC provides you perfect visual inspection.

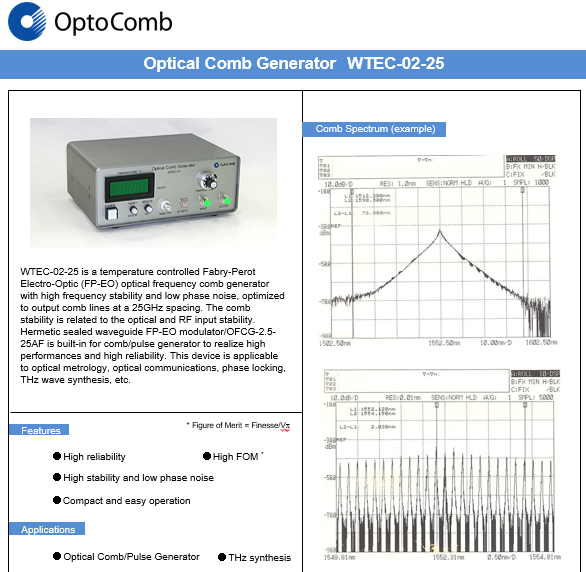

Optical Comb Generator is a module that generates an optical comb laser with temperature controller . Since it is a completely passive device, it produces a very stable optical comb.

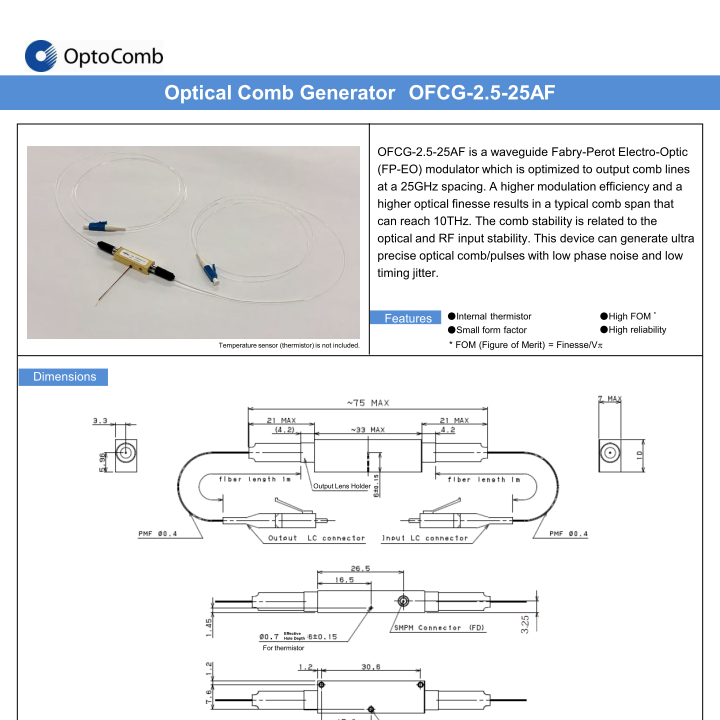

Optical Comb Module is a module that generates an optical comb laser without temperature controller. Since it is a completely passive device, it produces a very stable optical comb.

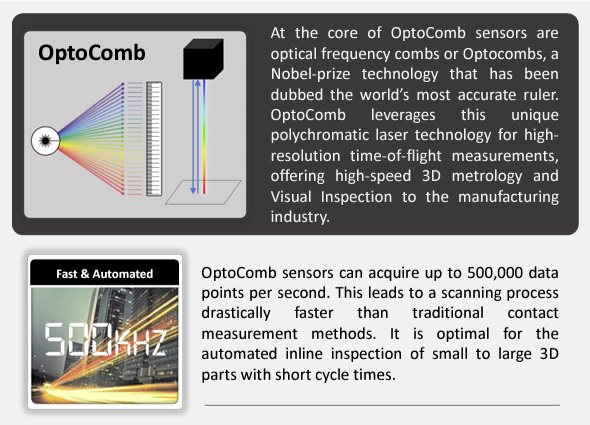

At the core of OptoComb sensors are optical frequency combs or Optocombs, a Nobel-prize technology that has been dubbed the world’s most accurate ruler. OptoComb leverages this unique polychromatic laser technology to offer high-speed and highresolution 3D metrology and Quality 4.0 solutions to the manufacturing

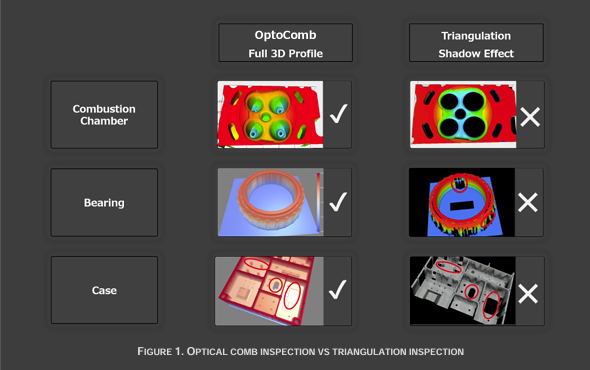

OptoComb's technology is based on Optocal Comb Frequency technologys, a coaxial laser system that scans objects and gives access to the full 3D profile of the most complex manufactured parts with high accuracy. OptoComb sensors are capable of measuring 500,000 data points per second.

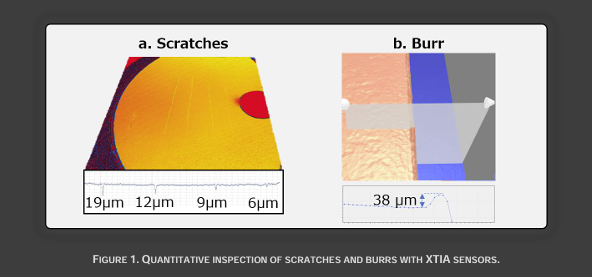

Engineering is a world where quantitative judgment should and can be made, but this has often been difficult to achieve on a manufacturing floor dominated by human inspection. With the automated inspection solutions offered by OptoComb, quantitative inspection and engineering of micrometer defects is finally possible.

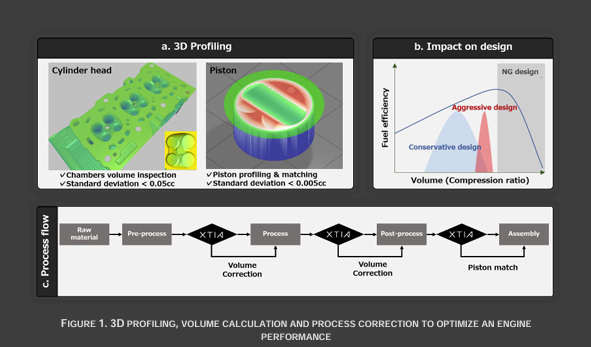

The OptoComb technology and our coaxial laser 3D scanners provide access to the dimensional profile of complex structures with high accuracy. As a result, OptoComb solutions can be extremely valuable if integrated within the manufacturing process flow, because it opens the door to the reduction of geometric tolerances by a specific correction process.

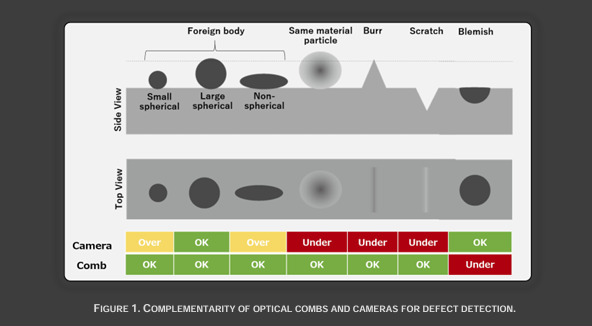

The reason why automated inspection is so difficult to implement is that there is a wide variety of defects to be inspected, and it is practically impossible to detect all of them with a single sensor. Conversely, using different sensors for different types of defects is time-consuming and costly, and as a result, it becomes a major barrier to automating the inspection process. The hybrid solution circumvents this barrier.

A wide range of manufacturing industries such as the automotive industry are supported by the outstanding capabilities of their manufacturing sites. The world’s attention is now focused on a future guided by the concepts of “Industry 4.0” and “Smart Factory” that aim at a radical shift toward an integrated factory