View more

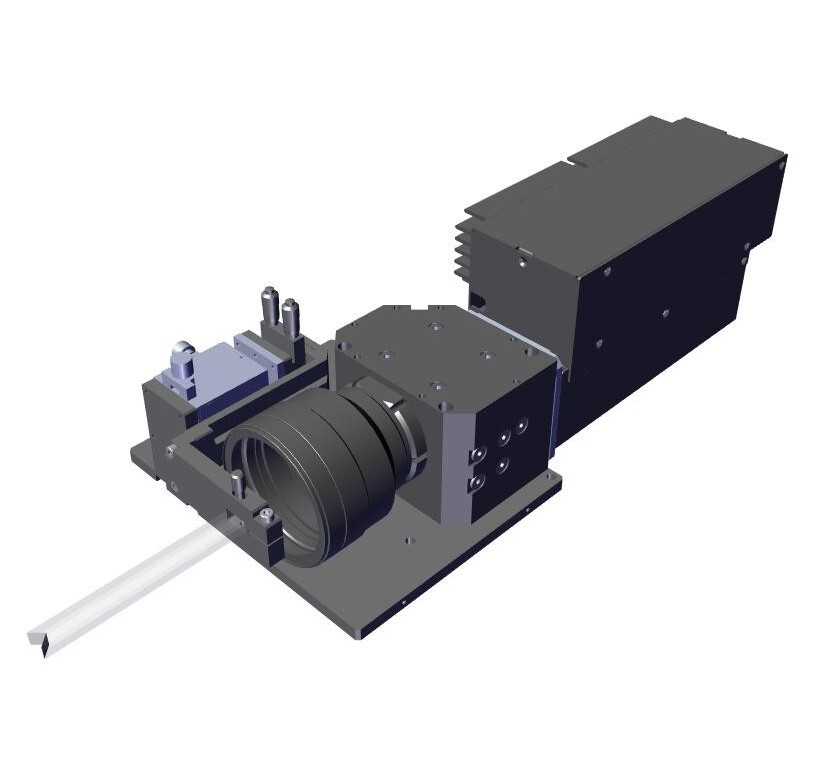

Optical Comb Generator is a module that generates an optical comb laser. Since it is a completely passive device, it produces a very stable optical comb.

It is best suited for research applications. There are two models to choose from: a stand-alone optical comb module and a temperature-controlled model.

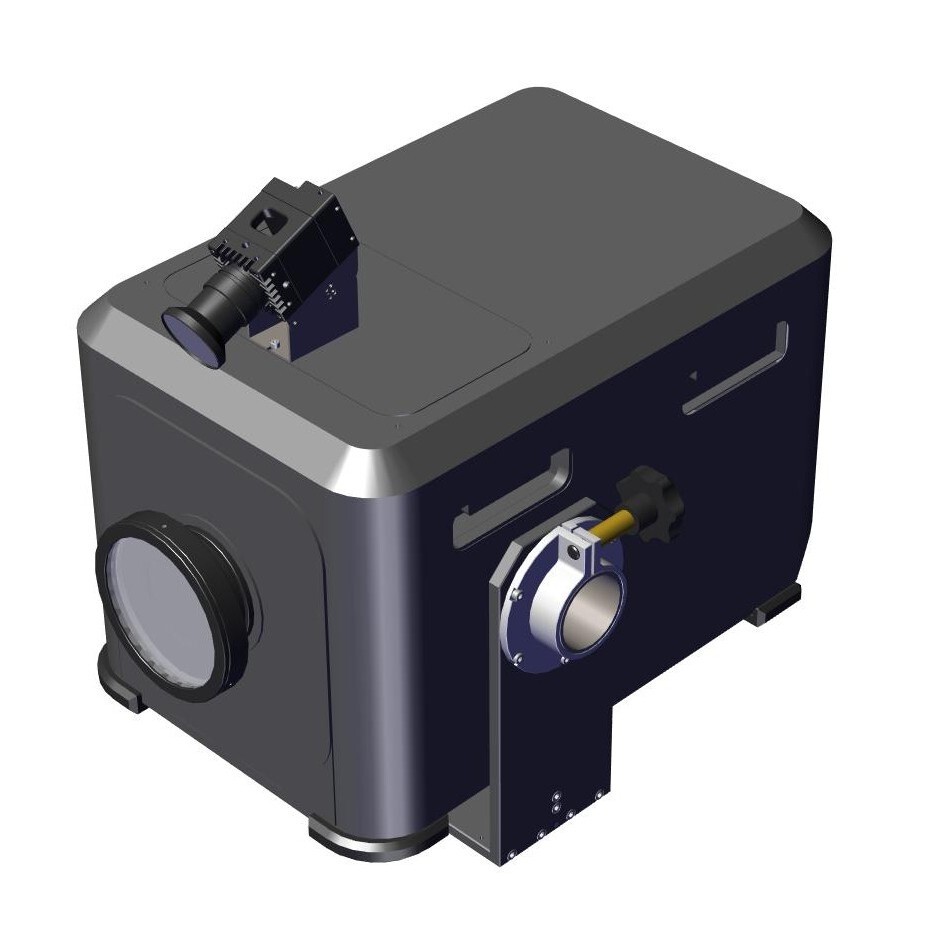

Optocomb 3D scanners are the first industrial application of the Nobel-prize winning Optocomb technology. With their coaxial configuration, their long working distance, their 500kHZ rate and a resolution as high as 1μm, OptoComb scanners are the ideal 3D scanning solution for a fully automated quality control. OptoComb scanners have a reliable track record for the GD&T of your most complex parts and for the detection of a large range of 3D defects such as dents, scratches, particles, burrs and more.

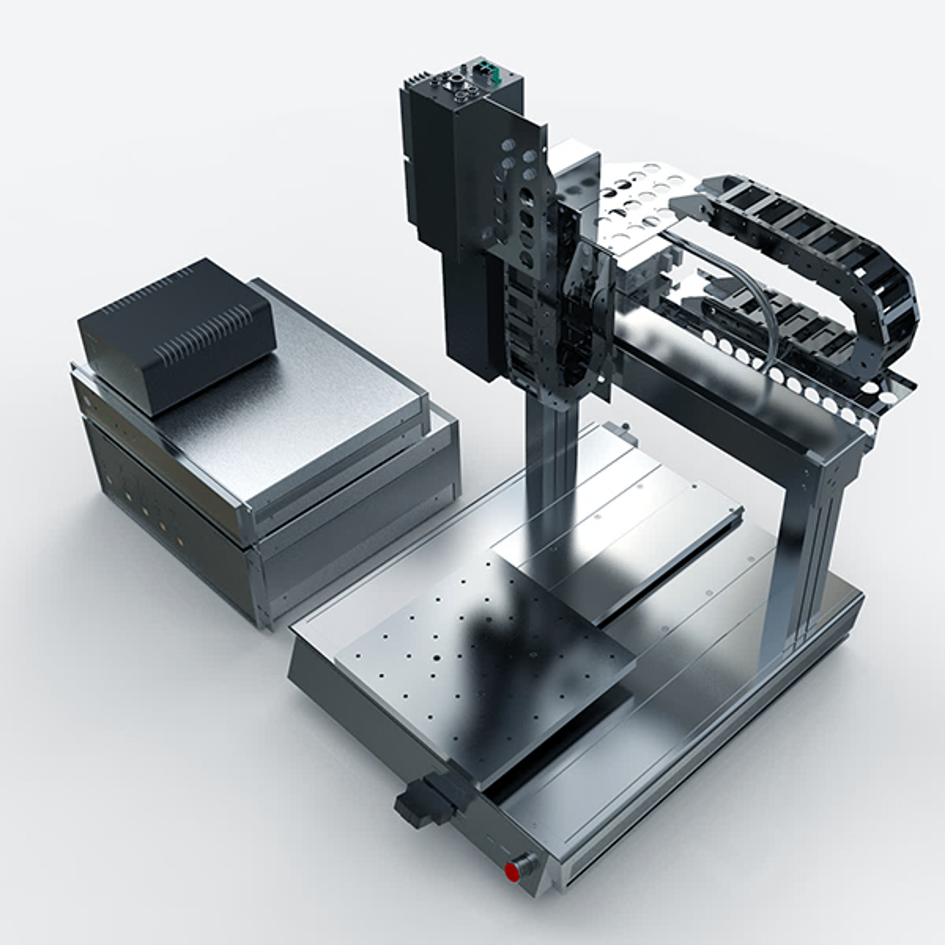

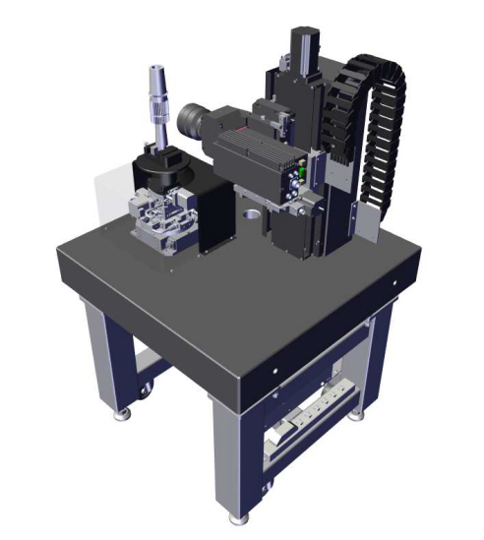

This is a base model of a 3D inspection device that utilizes Opto Comb 3D sensor. Inspect the top surface of the workpiece using the XYZ stage. It is possible to inspect the appearance, shape, and dimensions of parts with complex shapes, such as the machined surfaces of cast products with irregularities, in a single measurement. It can be used in a wide range of applications, including simultaneous inspection of multiple small workpieces lined up.

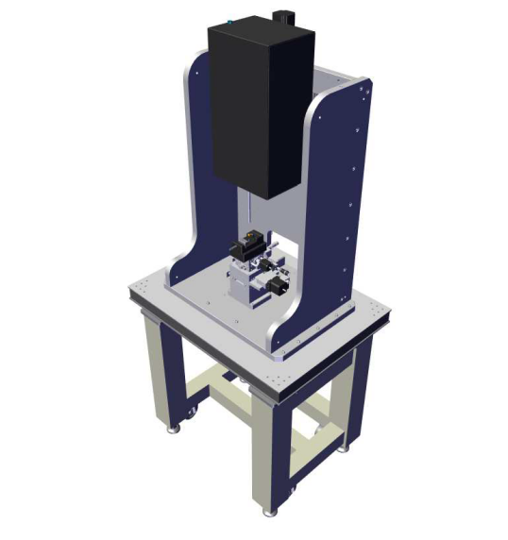

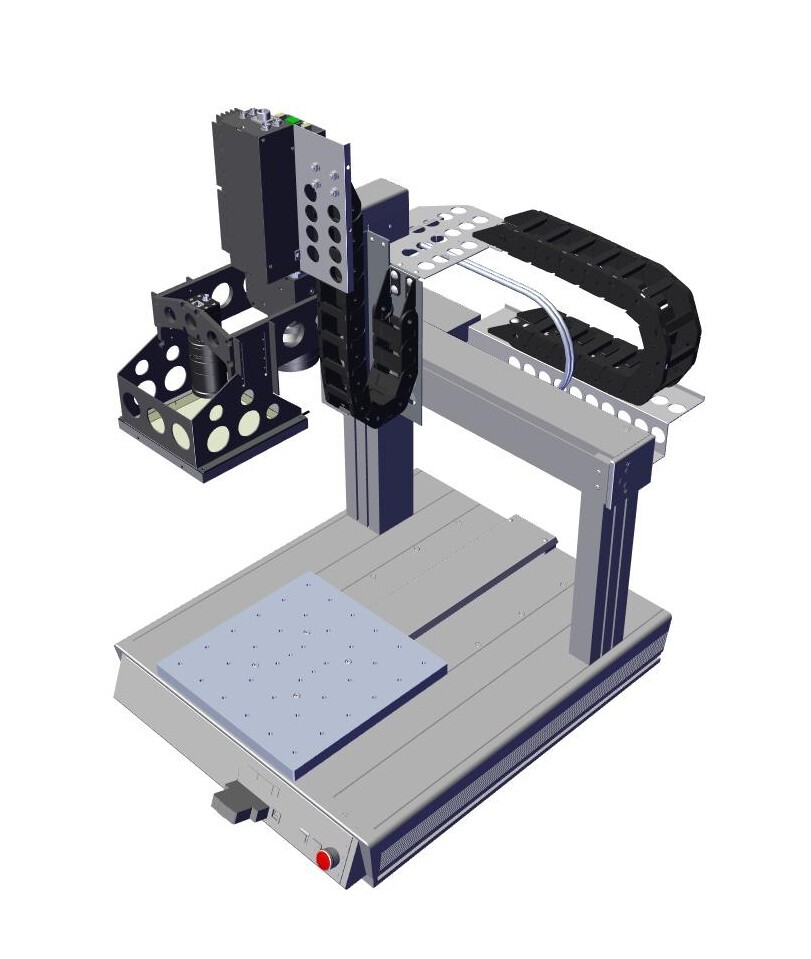

High-speed helical scanning using an optical comb laser makes it possible to inspect the inner surface of parts with high precision. Unlike existing internal surface inspection equipment, a single spindle can handle a wide range of diameters. Appearance, shape, and dimensions can be automatically inspected by measuring position. We can handle everything from general-purpose desktop inspection equipment to in-line 100% inspection.

OptoComb MPV, as the name stands, is the first vibrometer in the existence that enables a non-contact, full synchronization, of multi-point vibration measurement thanks to the Noble-prize awarded technology, the Optical Comb Frequency technology. OptoComb MPV has the ability to measure vibration of a rotating body, fully synchronous measurement, and also be able to measure vibration in 2D and 3D. It is truly a revolution in vibration measurement and anlysis.

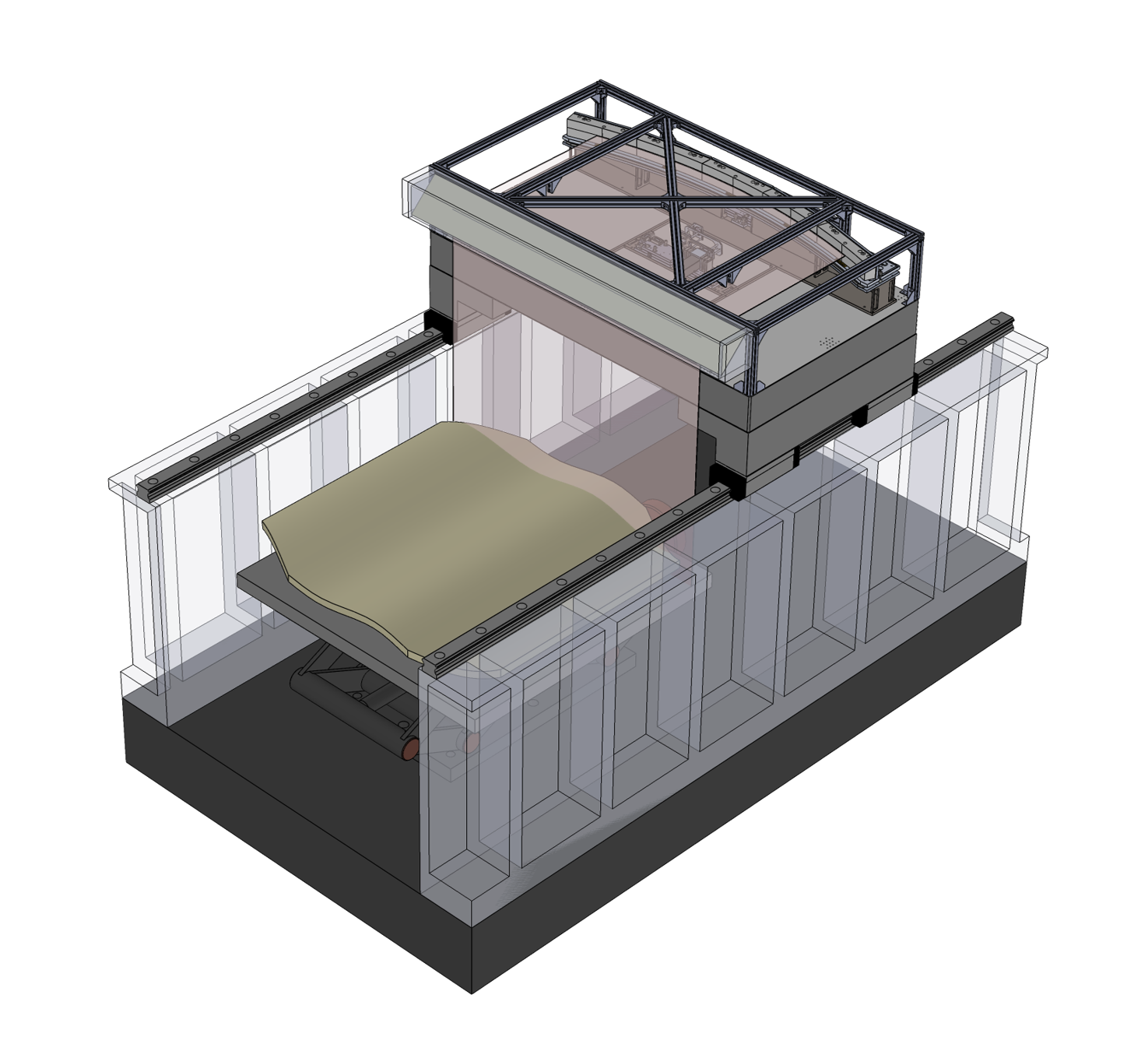

OptoComb XL series is a 3D measuremnet and inspection system for the application of extra-large workpieces. With the XL series solution, 3D measurement and inspection of large object ranging from 470~2000mm in width can be performed in one go. A solution that can only be provided by OptoComb, Inc. The system implements an ultra-fast data sampling frequency of 1.25MHz, which translate to 100 seconds measurement time for a 1000 x 1000mm area! Flatness inspection, uneven-ness evaluation of the surface of large panel is no longer a hassle with our new solution.

OptoComb 360 is a unique inspection system combining an OptoComb 3D scanner with a rotating stage to scan objects over 360°. With this system, we brings a new visual and dimensional inspection solution to the table and enables the outer surface of spools and other structures with rotational symmetry to be measured with high accuracy.

Leveraging their unique coaxial configuration and high accuracy, OptoComb 3D scanners can be combined with a 45° mirror to successfully inspect the inner walls of bores and complex cylindrical structures in seconds.

This model is equipped with an OptoComb SA (top surface inspection device), an image camera, and AI. Imaging is performed using an image camera, defect candidates are detected using AI at high speed, and the defect candidates detected by AI are measured using an optical comb 3D sensor. Measured areas are quantified in 3D based on rules, and complete 3D quantitative inspections can be performed at high speed.

Exclusive distributor in CHINA

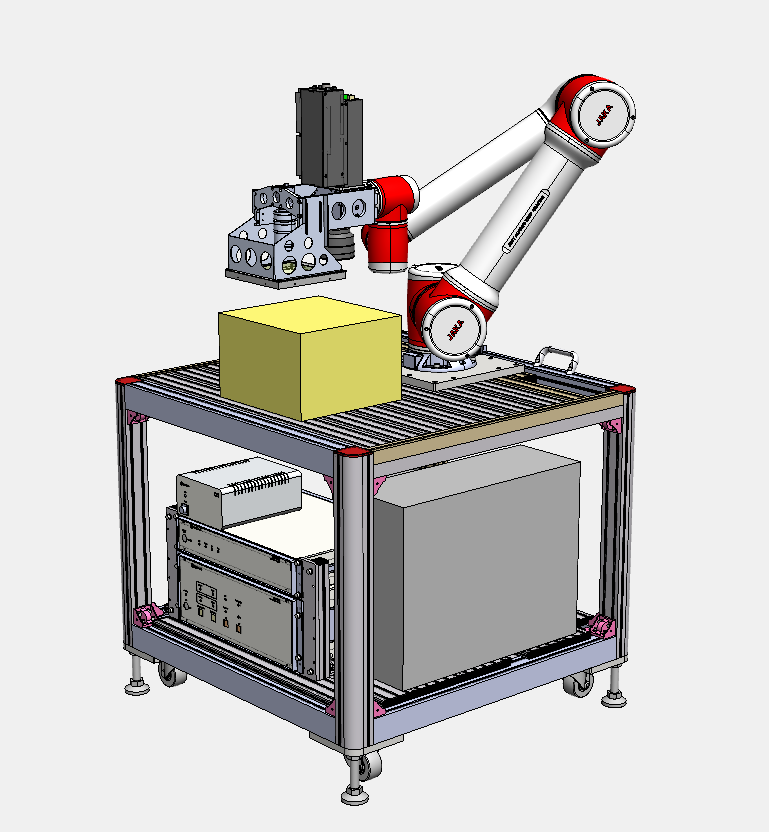

This is a top-of-the-line solution for automatic visual inspection that is equipped with a robot arm, an image camera, an optical comb 3D sensor, and AI. Defect candidates are detected quickly using an image camera and AI, and the defect candidates are measured using an optical comb 3D sensor. By using a robot arm, we can perform multi-sided inspection of large, complex-shaped workpieces.

Exclusive distributor in CHINA

View more

This is scanning software for acquiring optical comb 3D point cloud data.

Parameters such as scan area and pitch between points can be set, making it easy to optimize data acquisition conditions.

Main Functions

Getting 3D point cloud data measuring by Optical Comb technology

The viewer, visual inspection, and shape and dimension inspection software licenses are packaged for ease of use.

By combining the necessary licenses for everything from visualization of 3D point cloud data to analysis processing, it becomes easy to automate the inspection process.

Main Functions

・Optcomb Viewer

・Optcomb Detector

・Optcomb Measure

Scanning is performed based on the XYZ position sequence program.

By creating a sequence in advance, it is possible to scan in any combination of scan areas.

Main Functions

Can be defined the scan sequence by GUI and execute the scanning sequence

If you want to build inspection software or integrate with equipment, we can provide a software development kit to suit your on-site software development environment.

Main Functions

software development kit for inspection

View more