HARDWARE

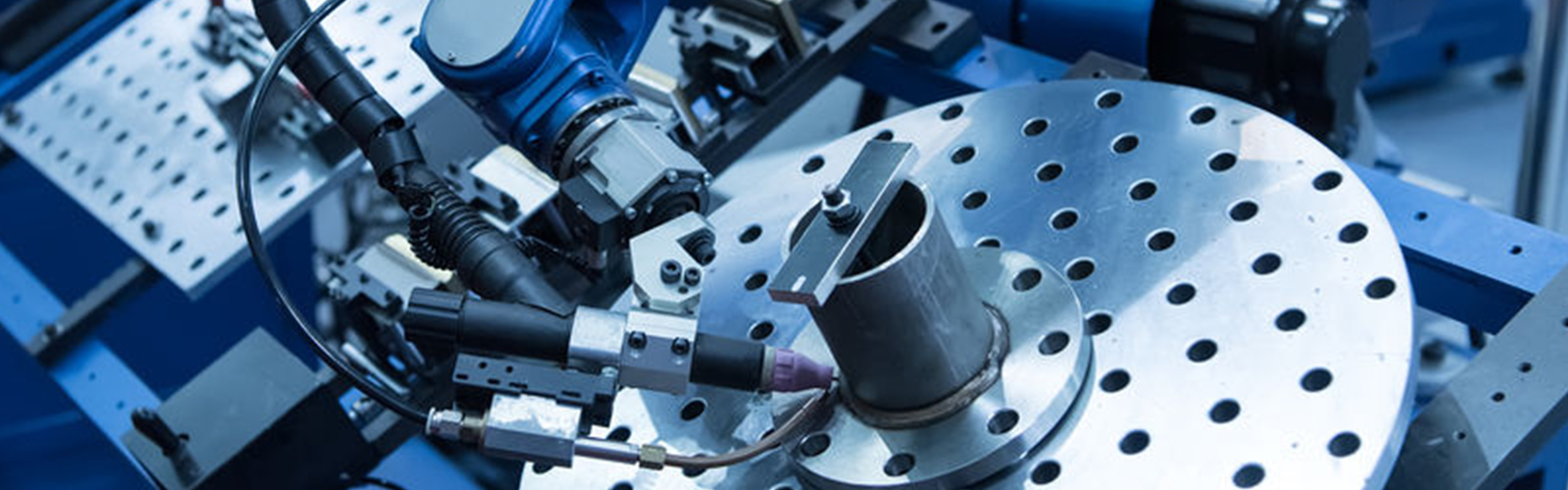

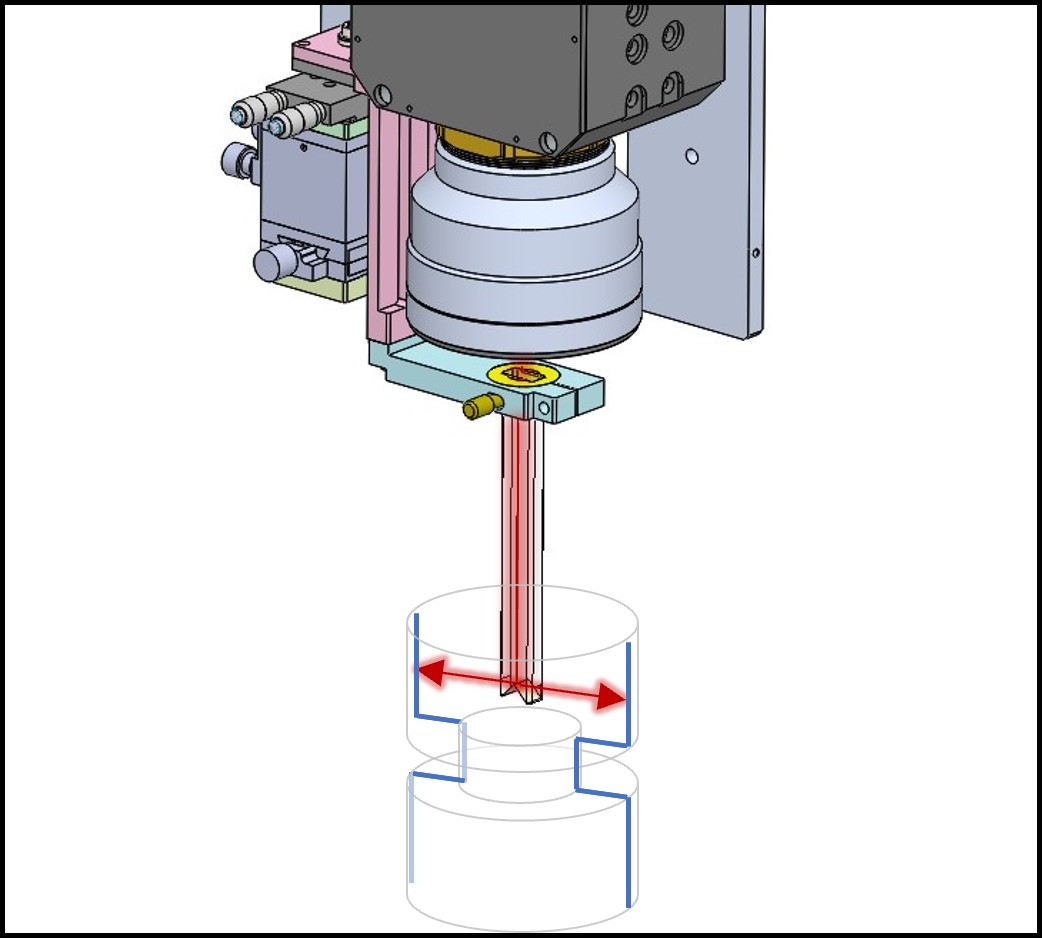

OptoComb MPV is A non-contact, full synchoronization of multi-point vibrometer.

OptoComb MPV redefined the limitation of traditional vibrometer which enables the vibration measurement of not only a stationary state but also a transitional object. This means that the vibration measurement of rotating body in real time is now possible with our new solution.

The hardware is applicable for performing complex assessment such as displacement, speed, acceleration, vibration, frequency and mode analysis.

We proudly introduces OptoComb MPV for a broad application from R&D to in-line inspection system.

View more

View more

● Fully sycbnchronized of multi-point vibration measuremnet is now possible due to the elimination of scanning and contact measurement features

● Synchronize vibration measurement of 52 channels (max)

● Suitable for complex assesment such as the displacement, speed, acceleration, vibration, frequency, and mode analysis of not only stationary state object but also transitional object

● Adaptability to the size and shape of measurement object - expendable head units

▼Are you experiencing these challenges?

・Difficulties in measuring vibration of a rotating body

・Difficulties to synchronize multiple measurement of vibration

・Need to measure vibration in 2D or 3D but have no means

・Need to implement a vibrometer as an in-line inspection system

・Incorporating big data in frequency analysis/mode analysis

Applications

View more

View more

ダダミーテキストミーテキストダミーテキストダミーテキストダミーテキストダミーテキストダミーテキストダミーテキスト

View more

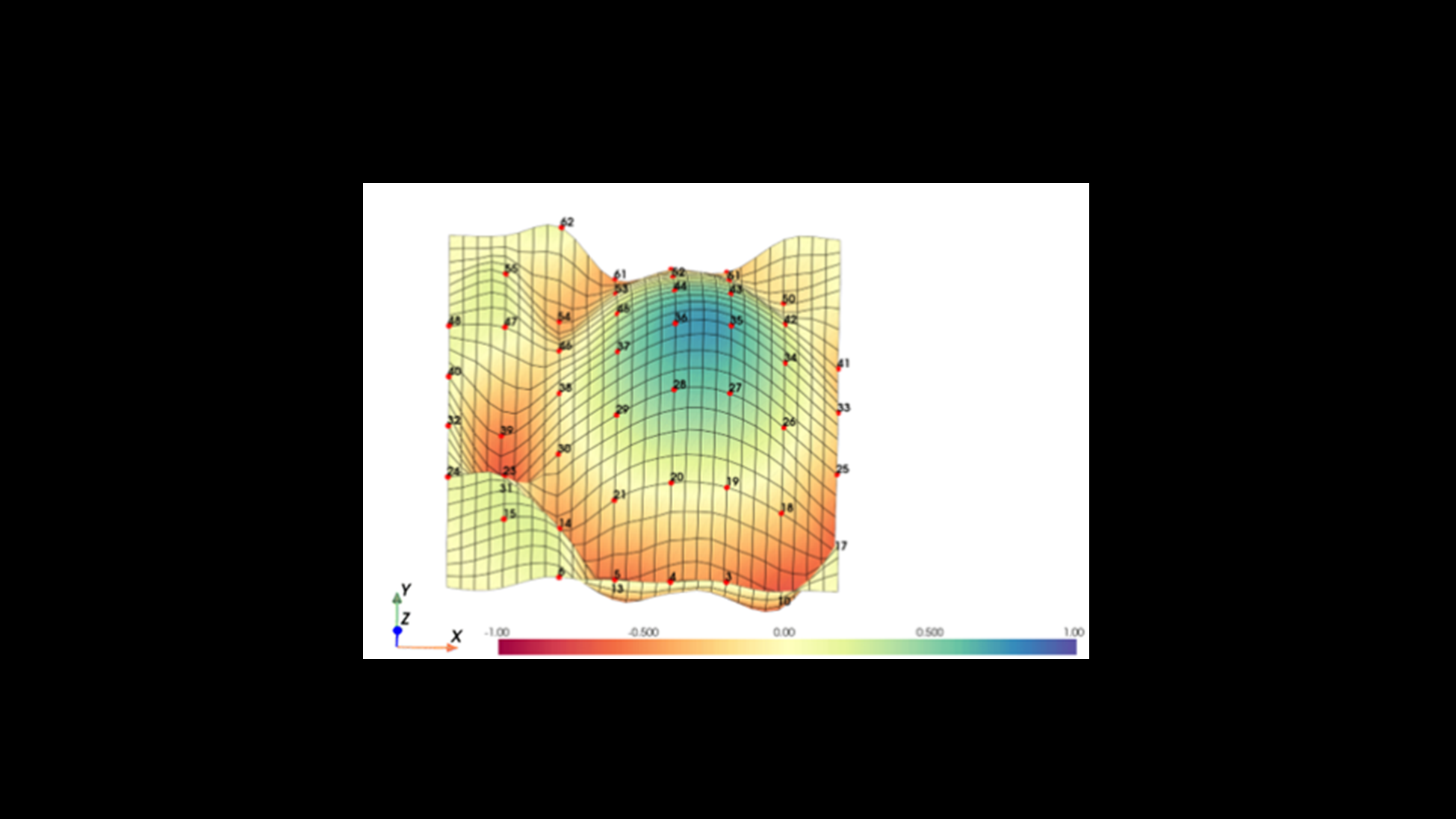

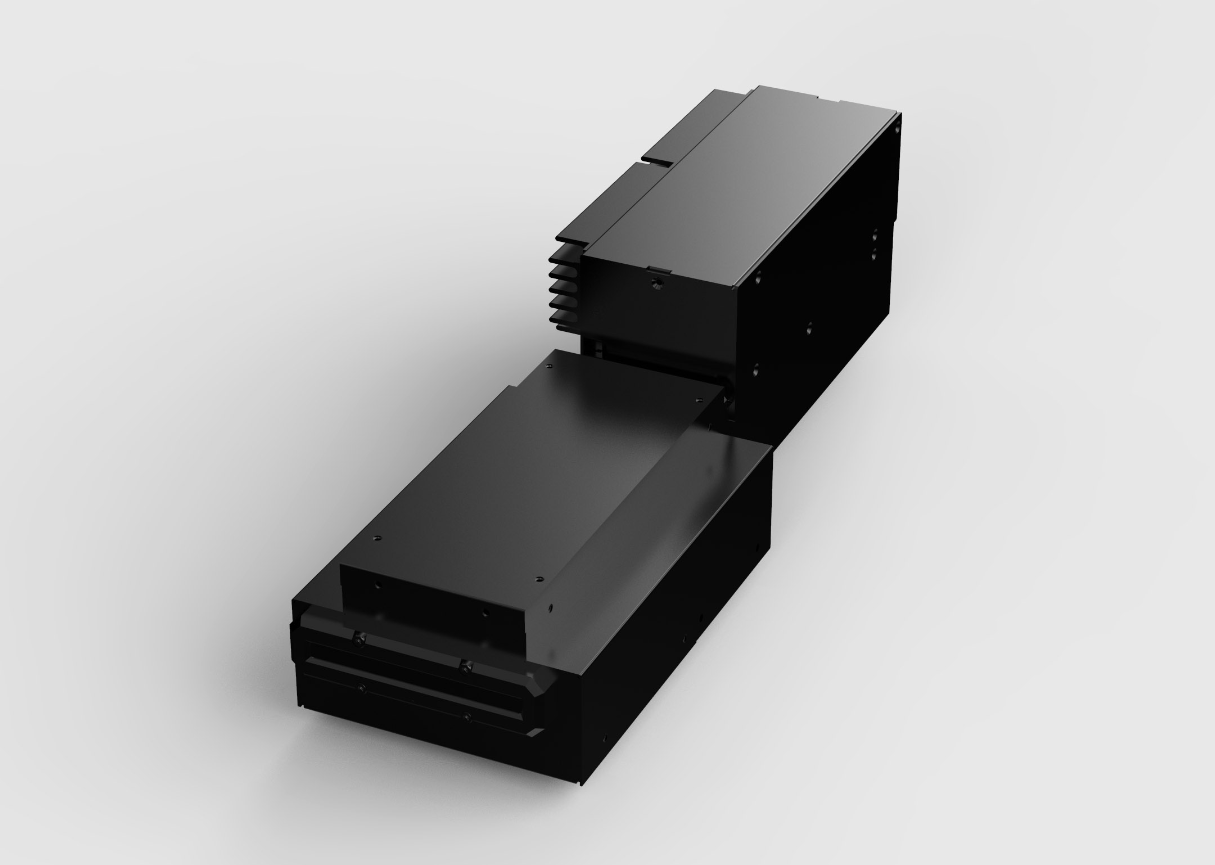

Optocomb 3D scanners by XTIA are the first industrial application of the Nobel-prize winning Optocomb technology. With their coaxial configuration, their long working distance, their 500kHZ rate and a resolution as high as 1μm, OptoComb scanners are the ideal 3D scanning solution for a fully automated quality control. OptoComb scanners have a reliable track record for the GD&T of your most complex parts and for the detection of a large range of 3D defects such as dents, scratches, particles, burrs and more.

不明

不明

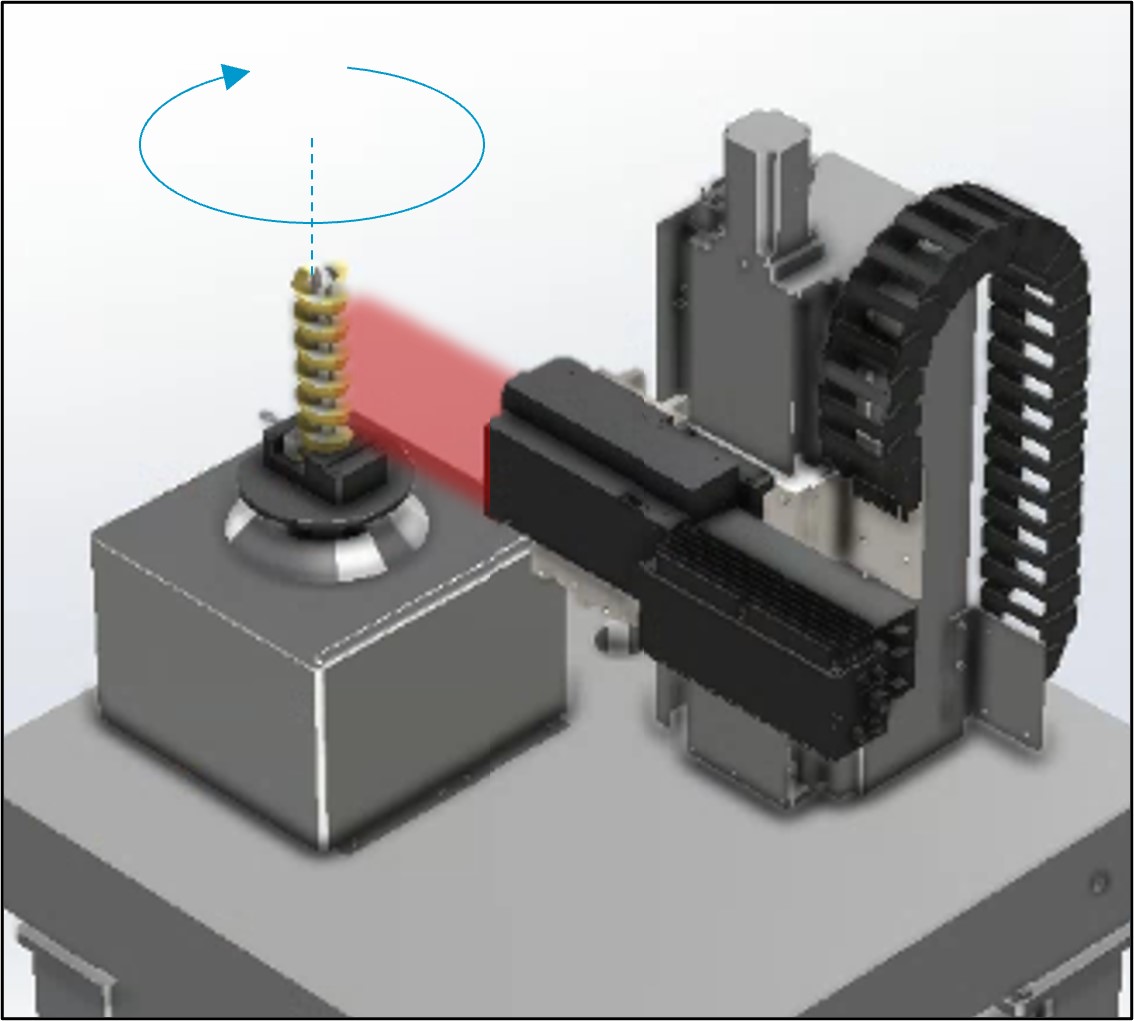

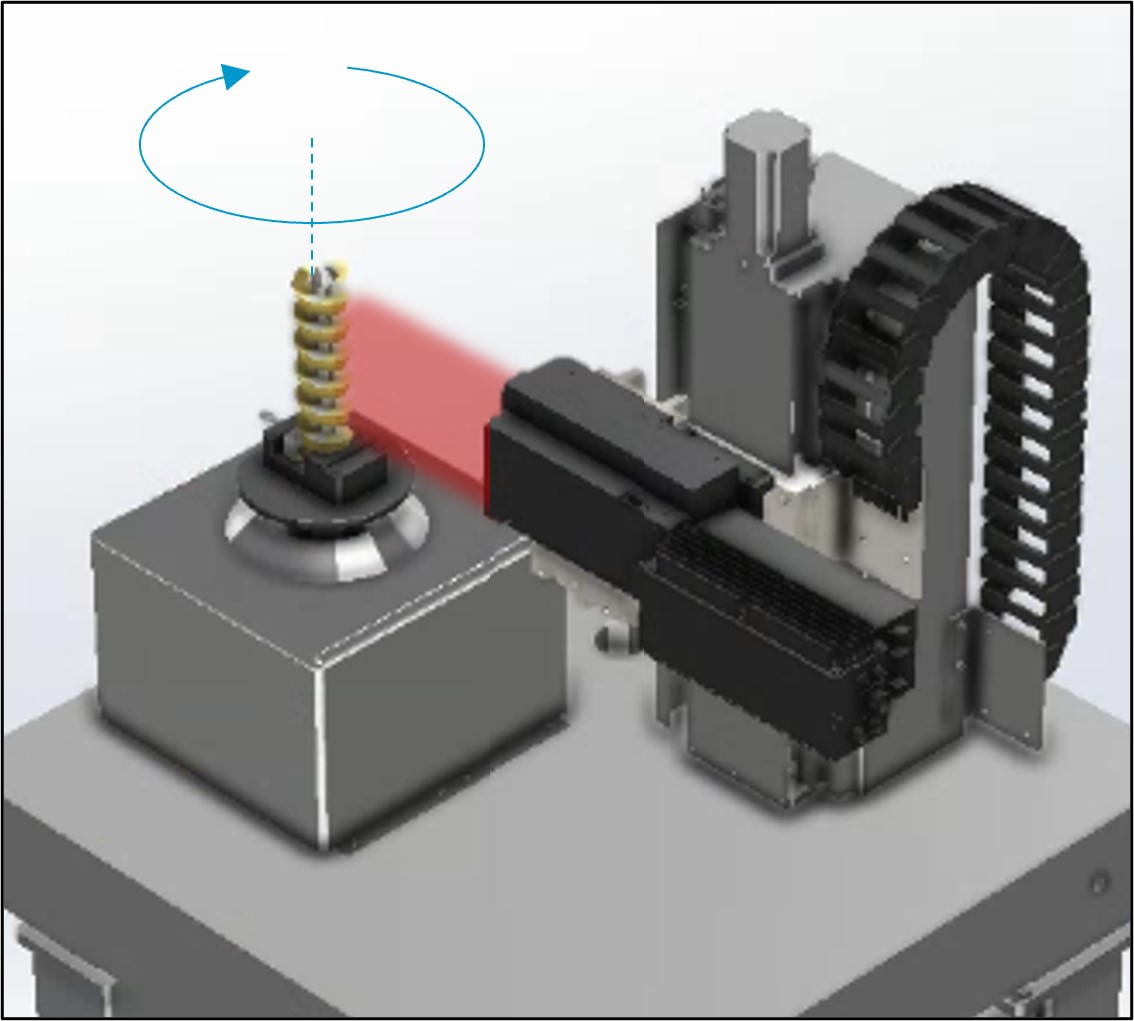

OptoComb 360 is a unique inspection system combining an OptoComb 3D scanner with a rotating stage to scan objects over 360°. With this system, XTIA brings a new visual and dimensional inspection solution to the table and enables the outer surface of spools and other structures with rotational symmetry to be measured with high accuracy.

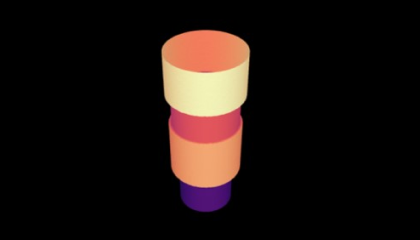

Leveraging their unique coaxial configuration and high accuracy, OptoComb 3D scanners can be combined with a 45° mirror to successfully inspect the inner walls of bores and complex cylindrical structures in seconds.

In collaboration with its partner JUKI, XTIA offers its Hybrid solution: a fully automated system integrating both a 12 Megapixel optical camera and a high-resolution S40 OptoComb 3D scanner. The system maximizes resolution in all three directions for an optimal visual inspection and defect detection process. By taking advantage of the very high speed of the optical camera, our hybrid system can reduce the cycle time of the overall automated inspection process.

不明

不明

不明