HARDWARE

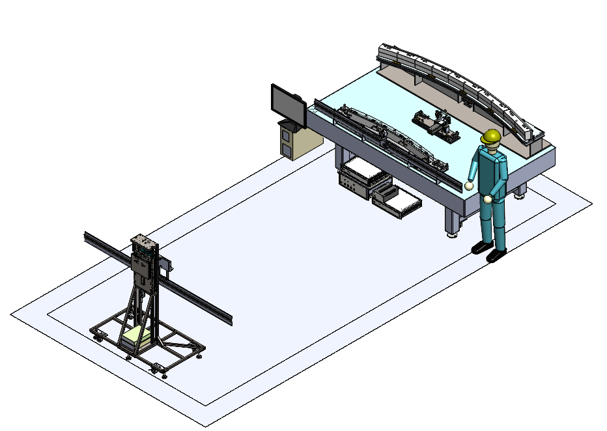

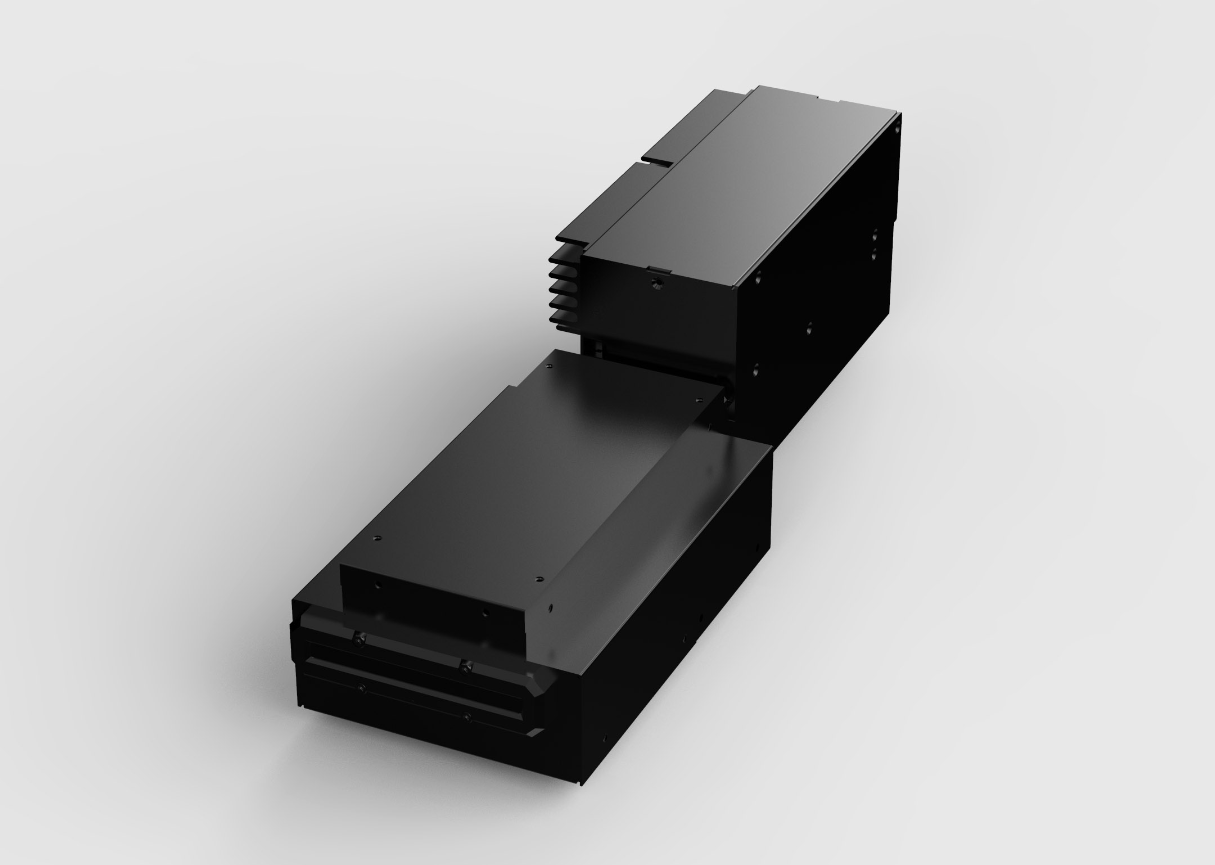

OptoComb XL series attains the superiority of optical comb 3D sensor while being applicable to extra-large workpiece. With our solution, 3D measurement and inspection of object ranging from 470~2000mm in width can now be performed in one go.

The sytem implements an ultra-fast data sampling frequency of 1.25MHz - an enhancement of 2.25 times to the previous model.

We proudly introduces OptoComb XL for a broad application from R&D to in-line inspection system.

View more

View more

● We have expanded our 3D measurement system so it is applicable to extra-large workpiece but everything superior about our existence system is maintained - high speed 3D data conversion, measure complex shaped object, micron level resolution, resistency to ambient light

● An improved measurement speed (2.25 times faster than the previous model) - measuring 125,000 data points per second!

● Has the ability to measure depth in Z direction at a very high precision of 1μm

▼Are you experiencing these challenges?

・Difficulties in measuring flatness and uneven-ness of large panel

・Performing 3D inspection of large object without compromising accuracy

・Attaining high speed 3D measurement regardless the increase in object size

・Measuring large area object in point cloud data

Applications

View more

View more

ダダミーテキストミーテキストダミーテキストダミーテキストダミーテキストダミーテキストダミーテキストダミーテキスト

View more

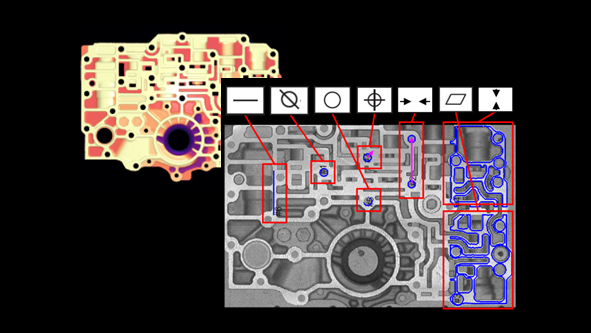

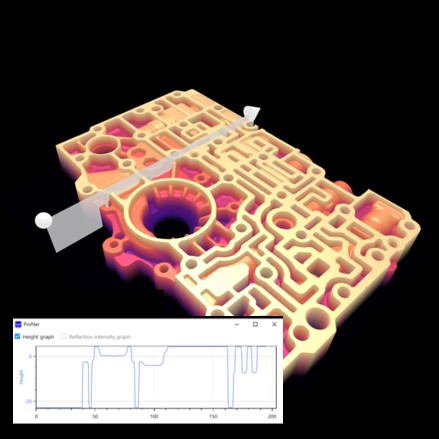

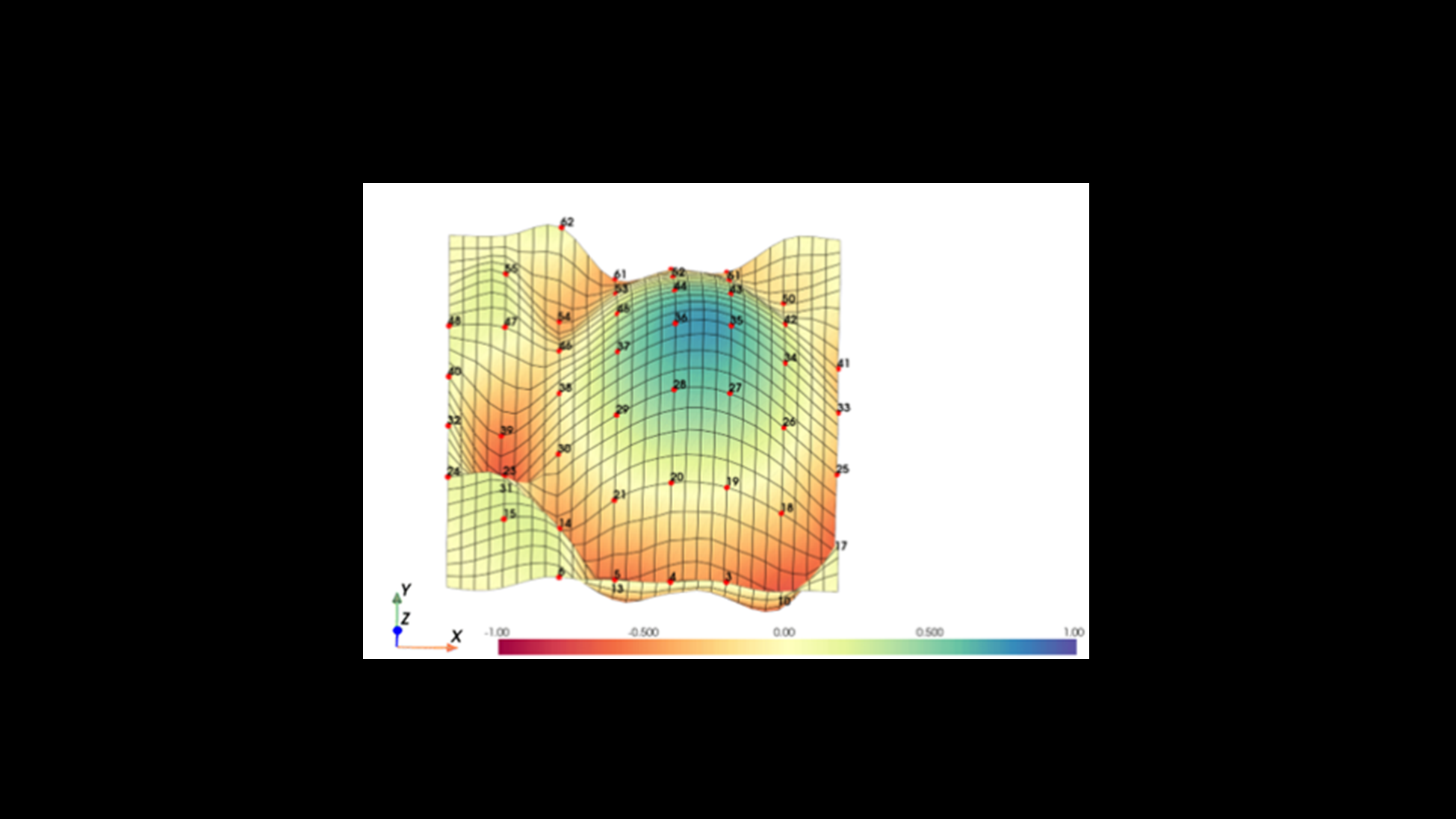

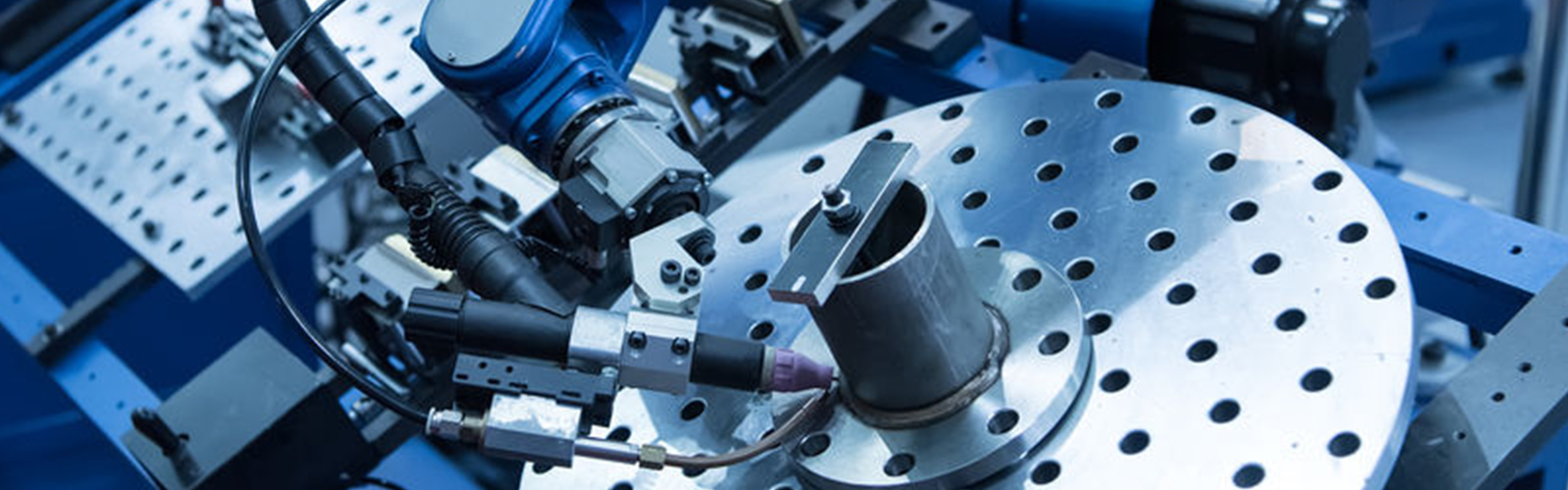

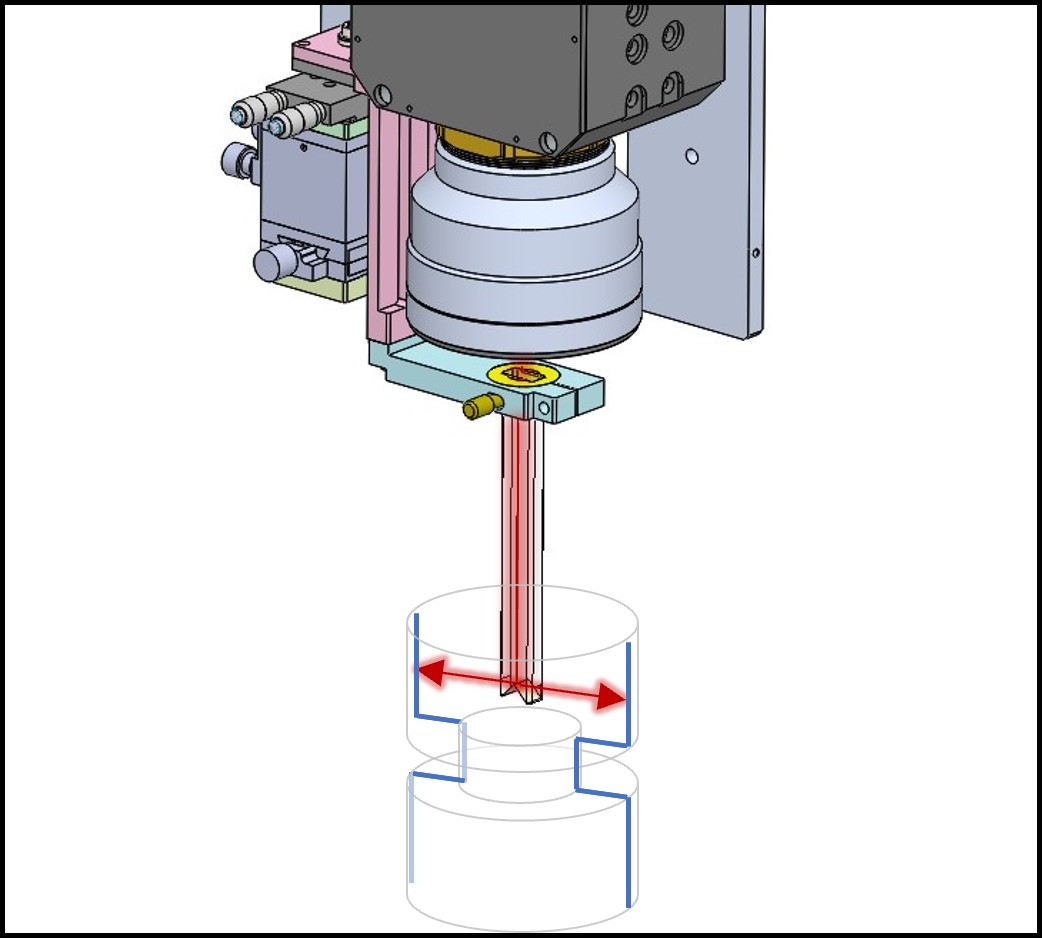

Optocomb 3D scanners by XTIA are the first industrial application of the Nobel-prize winning Optocomb technology. With their coaxial configuration, their long working distance, their 500kHZ rate and a resolution as high as 1μm, OptoComb scanners are the ideal 3D scanning solution for a fully automated quality control. OptoComb scanners have a reliable track record for the GD&T of your most complex parts and for the detection of a large range of 3D defects such as dents, scratches, particles, burrs and more.

不明

不明

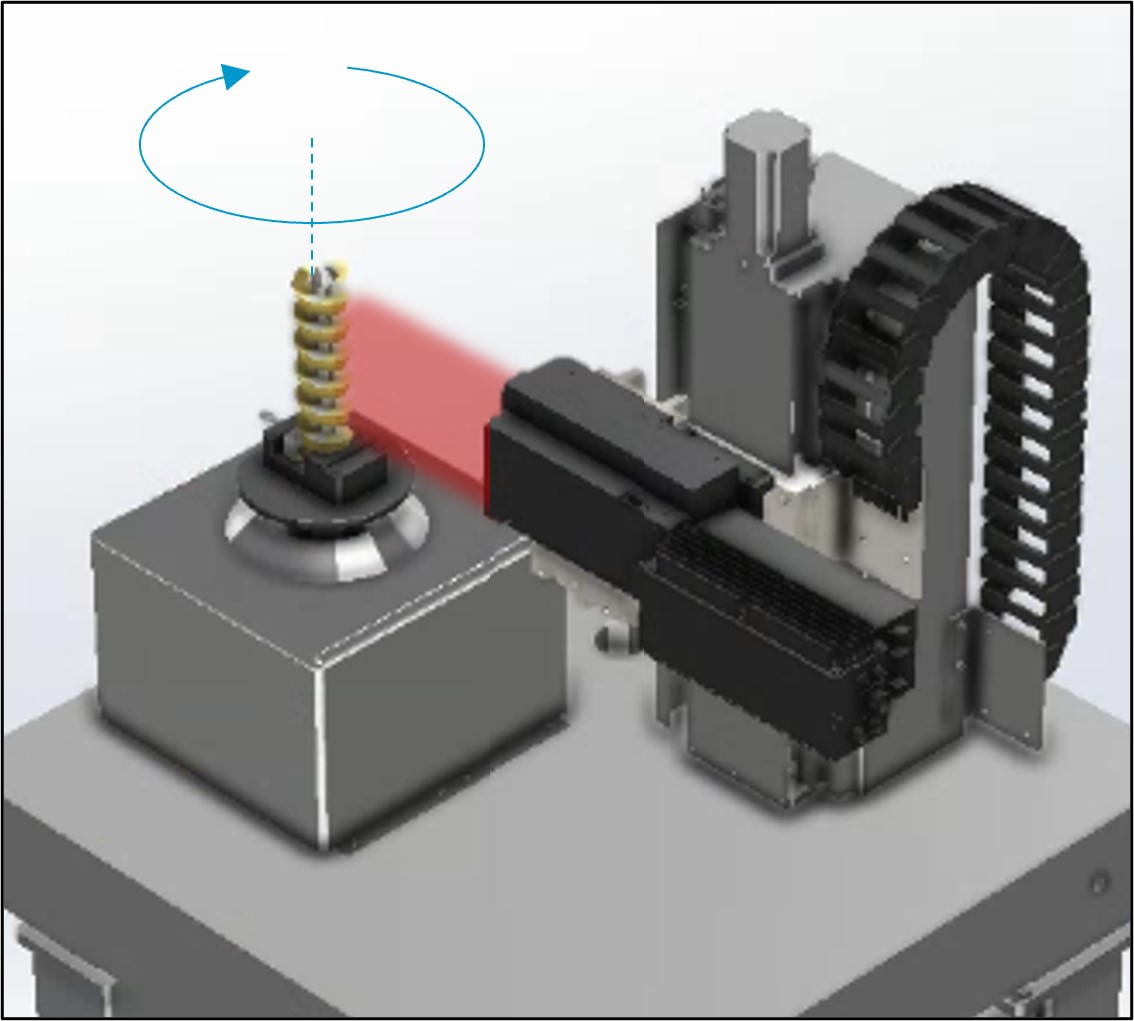

OptoComb 360 is a unique inspection system combining an OptoComb 3D scanner with a rotating stage to scan objects over 360°. With this system, XTIA brings a new visual and dimensional inspection solution to the table and enables the outer surface of spools and other structures with rotational symmetry to be measured with high accuracy.

Leveraging their unique coaxial configuration and high accuracy, OptoComb 3D scanners can be combined with a 45° mirror to successfully inspect the inner walls of bores and complex cylindrical structures in seconds.

In collaboration with its partner JUKI, XTIA offers its Hybrid solution: a fully automated system integrating both a 12 Megapixel optical camera and a high-resolution S40 OptoComb 3D scanner. The system maximizes resolution in all three directions for an optimal visual inspection and defect detection process. By taking advantage of the very high speed of the optical camera, our hybrid system can reduce the cycle time of the overall automated inspection process.

不明

不明

不明