Visual and dimensional inspection in a single scan

・説明のテキストが入ります。・説明のテキストが入ります。

・説明のテキストが入ります。・説明のテキストが入ります。

・説明のテキストが入ります。・説明のテキストが入ります。

・説明のテキストが入ります。・説明のテキストが入ります。

・説明のテキストが入ります。・説明のテキストが入ります。

・説明のテキストが入ります。・説明のテキストが入ります。

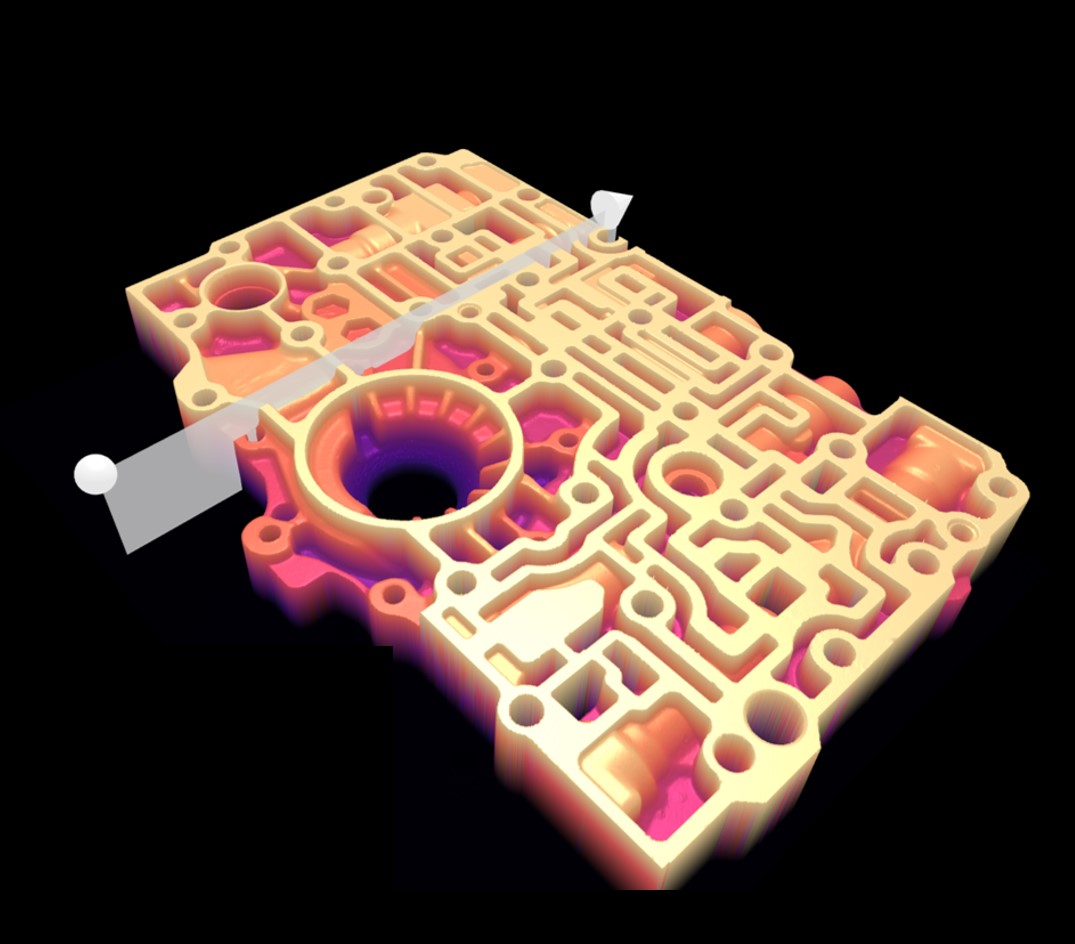

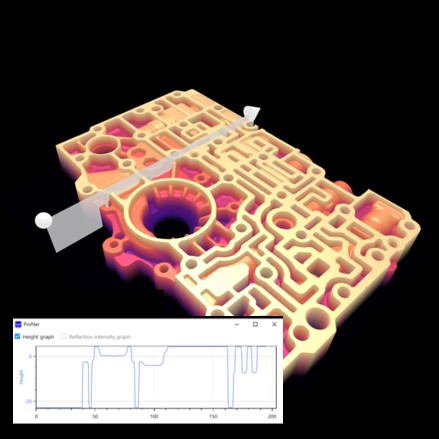

・Full 3D profile in a single scan

・Fast & automated scanning

・User-friendly measurement and analysis

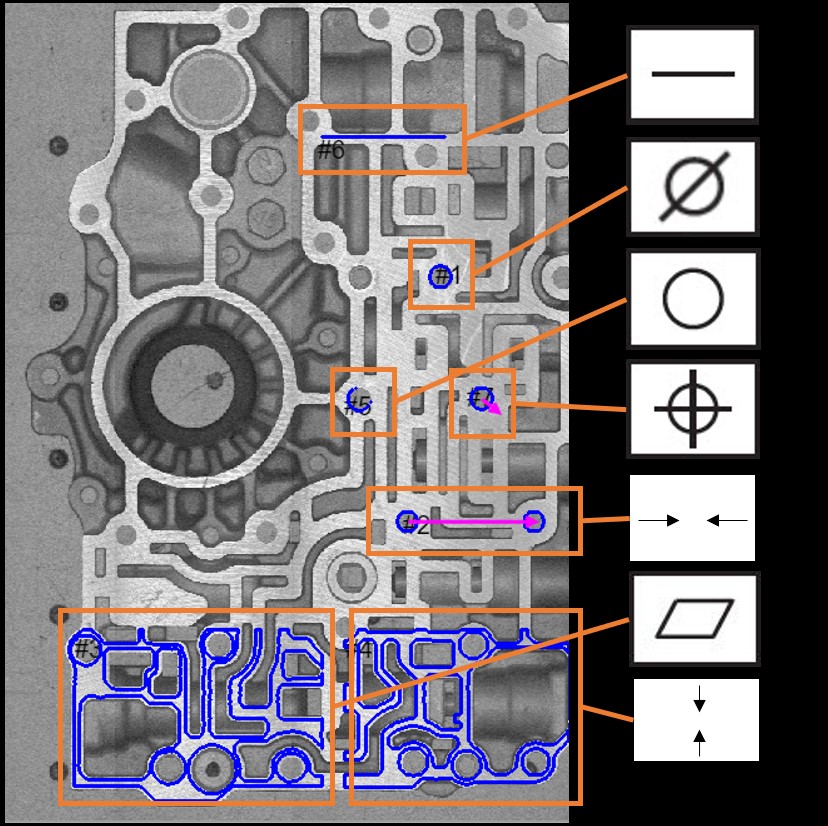

・Automated GD&T anaysis

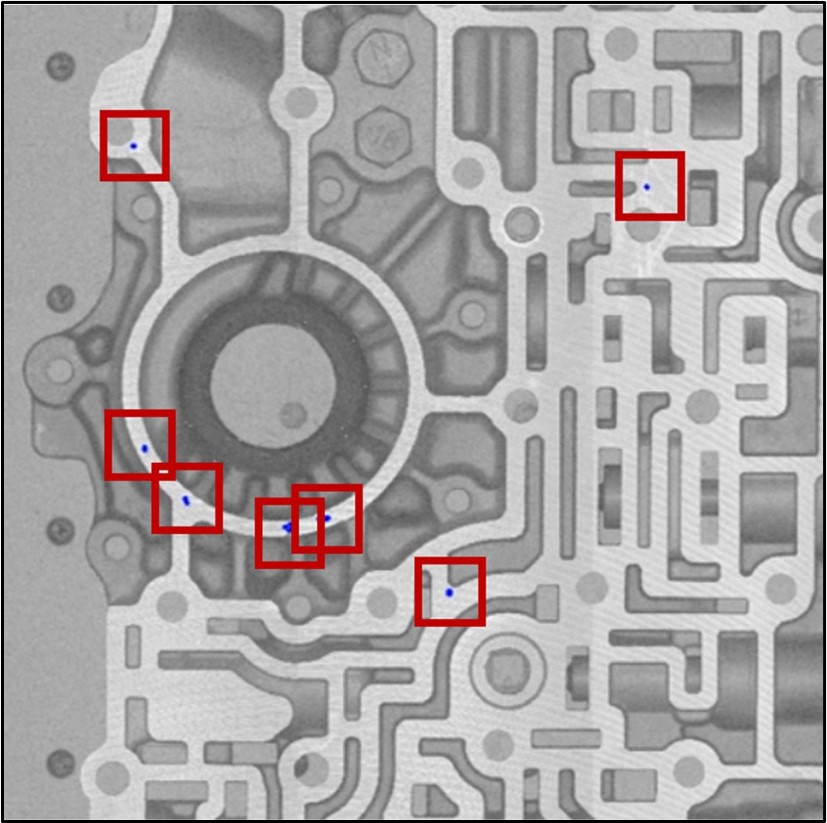

・Automated detection of microdefects

・Automated inspection report generation

・Export your data and inspection reports

Automating the inspection process of complex parts such as valve bodies can be a difficult task for manufacturers because traditional methods are either slow or do not provide access to the full 3D profile. With their coaxial configuration and long working distance, Optocomb 3D scanners by XTIA circumvent such difficulties and can give access to the smallest features and defects of a valve body without any shadowing effect. Manufacturers can also leverage the 500,000 points/sec scanning rate of our 3D scanners to fully automate the quality control of their valve body and perform the visual and dimensional inspection process in-line with micrometer resolution.

XTIA's comprehensive metrology software, the Optocomb Suite, can fully integrate the inspection process from measurement of the valve body to 3D data processing and automated GD&T analysis. In particular, the Optocomb Ruler toolbox can generate customized inspection recipes, and perform the dimensional inspection in parallel to the measurement process. It automatically regognizes the part's features and extracts all the tolerances of the valve body with high resolution: positional deviation, diameter, roundness, flatness, straightness, parallelism and more.

Beyond dimensional inspection, a single 3D scan of the valve body with our L90 Optocomb scanner gives access to sub-millimeter defects such as dents, scratches and voids. Smaller defects such as micro-scratches, burrs and particles can also be inspected with our high- and ultra-high resolution scanners S40 and M5. Based on such high-resolution 3D data, the Optocomb Detector toolbox can automatically detect, identify and quantify the size of defects in all three dimensions. With such quantitative information, manufacturers can fully control the manufacturing process of their valve body and optimize their manufacturing line.