Automated GD&T analysis and visual inspection with Optocomb 3D scanners

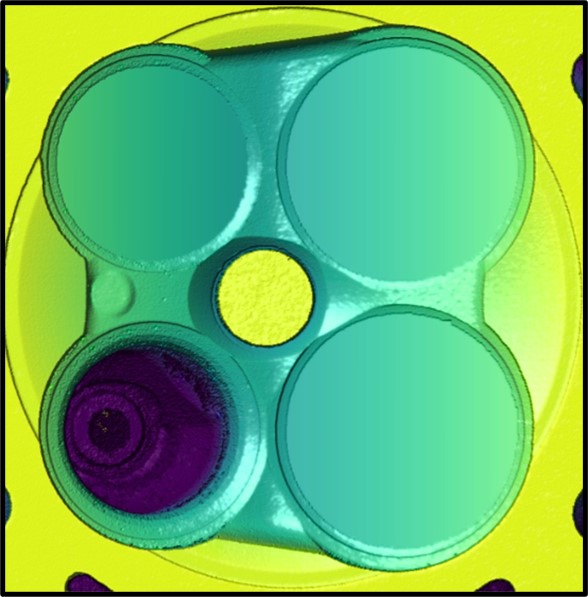

> Measurement of combustion chamber volume

> All of inspection automatically in line

> Inspection equipment cannot reach deep areas when inspecting complex shapes.

> Know the volume after processing.

> Full 3D profile of your cylinder head

> Short scanning time

> User-friendly measurement and analysis

> Volume calculation of combustion chambers

> Automated GD&T analysis

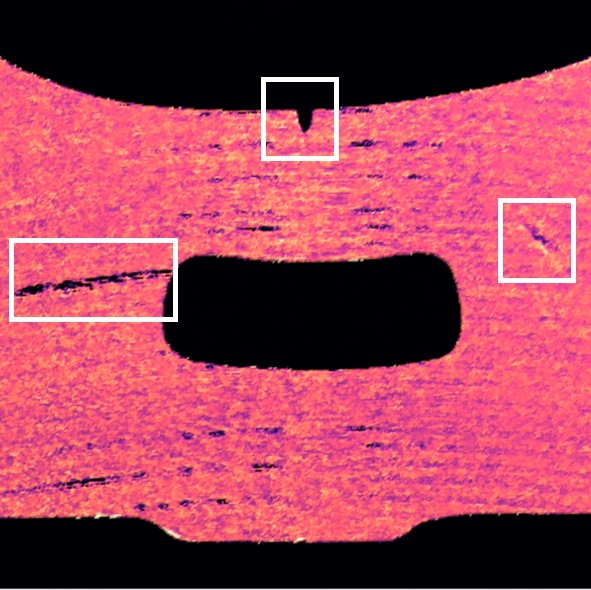

> Automated defects detection

> Automated inspection report generation

> Export your data and inspection reports

With our unique Optocomb 3D scanners based on a Nobel-prize-winning concept, you can fully profile your cylinder head with microscale accuracy, enabling both dimensional and visual inspection in a single scan. Optocomb 3D scanners can measure 500,000 points per seconds and can complete a full cylinder head scan with a fine pitch in a few tens of seconds. It is significantly faster than traditional contact CMM inspection methods, but it is also more flexible and user-friendly as no measurement recipe is needed.

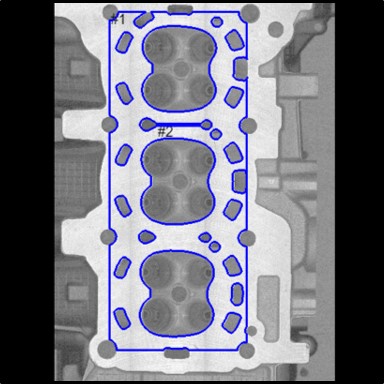

With their coaxial configuration and long working distance, Optocomb 3D scanners are ideal to measure the full 3D profile of the combustion chambers. The Optocomb Suite, our comprehensive metrology software can process this data to extract the volume of each chamber with high accuracy. Our clients routinely leverage the L90 Optocomb scanner to optimize their cylinder head manufacturing process, reduce the volume variations of combustion chambers below 0.01cc, and boost their engine performance.

With the Optocomb Suite, you can also automatically process your high-resolution Optocomb 3D data to automate the GD&T analysis of your cylinder head. Based on your own custom recipe, our metrology software can automatically detect the cylinder head’s features, and instantly assess all the tolerances of your part: diameters, positional deviation, flatness, straightness, parallelism, roundness and more. The GD&T analysis results of the cylinder head can be easily exported and plugged into your quality management system.

In a single scan you can even go beyond dimensional inspection and perform the visual inspection of your cylinder head. With our L90 wide-range 3D sensor, you can assess the surface finish of the cylinder head with a 10 micrometer resolution. You can detect identify and quantify polishing defects, dents and particles. Our high-resolution sensors S40 and M5 can even achieve a resolution as high as 1 micrometer to automatically inspect even smaller 3D micro-defects such as burrs and scratches.