Get access to the 3D profile of your bore at the micrometer scale.

> Bore inner surface inspection

> Inner diameter dimension inspection

> Difficult to measure dimensions of cylindrical parts and detect scratches

> No way to inspect the scratches and dimensions of the inner surface of cylindrical parts.

> Full 3D profile of inner walls

> 2 μm radial resolution

> Fast & automated scanning

> 3D visualization in cartesian/cylindrical coordinates

> User-friendly measurement and analysis

> Automated detection of microdefects

> Automated inspection report generation

> Export your data and inspection reports

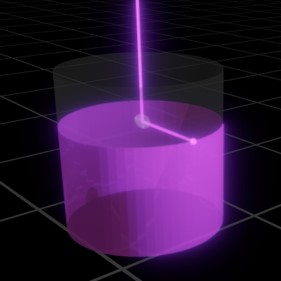

Many medium and large parts have cylindrical features that need to meet high quality requirements and the ever-demanding designs of modern manufacturing. To tackle this issue, we have leveraged the coaxial configuration of our OptoComb 3D scanners to offer custom soutions dedicated to the inspection of bores. By combining our OptoComb 3D scanner with a rotating mirror that translates within the structure along its rotating axis, we can probe the inner walls of bores and extract their 3D profile. With helical scan

configuration, we bring a new visual and dimensional inspection solution to the table and allow the inner surface of bores and other cylindrical structures to be measured with high-speed and micrometer accuracy.

With a scanning rate of 500,000 points per seconds, Helical Scan is thus the ideal solution for the in-line inspection of bores for 100% of manufactured parts. It gives direct access to the position, diameter, cylindricity, circularity and depth of your bores and cylindrical structures with diameters larger than 20 mm. Our helical scan configuration can thus be applied to a broad range of manufactured parts, including cylinder blocks, brake valves, solenoid valves, bearings, conrods, and many more.

Detecting micrometer defects in bores is notably difficult with traditional inspection methods. Yet, microdefects can lead to significant dysfunction during the assembly process or the final product operation. With our helical scan configuration, you can dive deep into bores and perform the visual inspection of the smallest particles, scratches and bulges of your manufactured parts with high resolution. You can thus not only detect and identify microdefects but also get access to their size in all three dimensions. With such quantitative information, manufacturers can fully engineer their manufacturing process and rationalize their production system.