The 3D profile of your bearing at the micrometer scale.

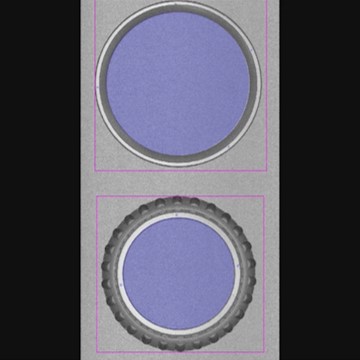

> By using optical comb technology that is resistant to external light, it can detect flaws in gear meshes with complex shapes.

> Depending on the type of measuring device, shadows may appear due to ambient light, making detection difficult.

> No solution to measure the outer surface, surface, and interlocking parts together.

> Full 3D profile of your bearing

> High resolution

> Fast & automated scanning

> User-friendly measurement and analysis

> Automated GD&T analysis

> Automated detection of microdefects

> Automated inspection report generation

> Export your data and inspection reports

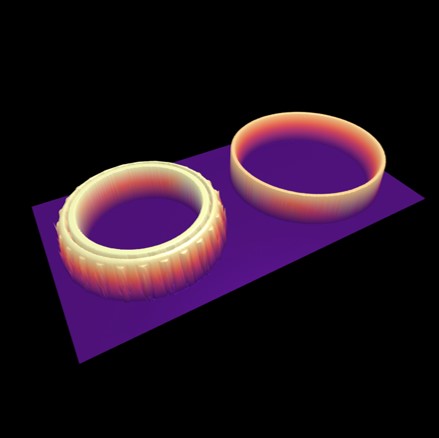

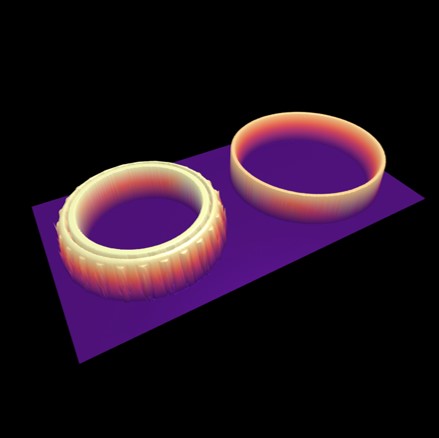

Automating the quality control of complex parts such as bearings can be a difficult task for manufacturers because traditional methods are either slow or only provide a partial profile because of shadowing effects. With their coaxial configuration and long working distance, Optocomb 3D scanners circumvent such difficulties and scan the smallest features and defects of the bearing without any shadowing effect. By integrating the Optocomb 3D scanners in-line, manufacturers can also leverage the 500,000 points/sec scanning rate of our 3D scanners to perform the inspection of 100% of manufactured bearings without human intervention.

OptoComb 3D scanners are supplemented by a comprehensive metrology software, the Optocomb Suite, that fully automates the quality control process from part measurement to data processing and quality assessment. With the Optocomb Ruler toolbox manufacturers can for example generate their own dimensional inspection recipe and automatically perform the GD&T analysis in parallel to the scanning of the bearing. They can thus easily leverage the high-resolution scanning data to assess tolerances (positional deviation, diameter, roudness, flatness and more), enhance their quality control system and optimize their manufacturing line.

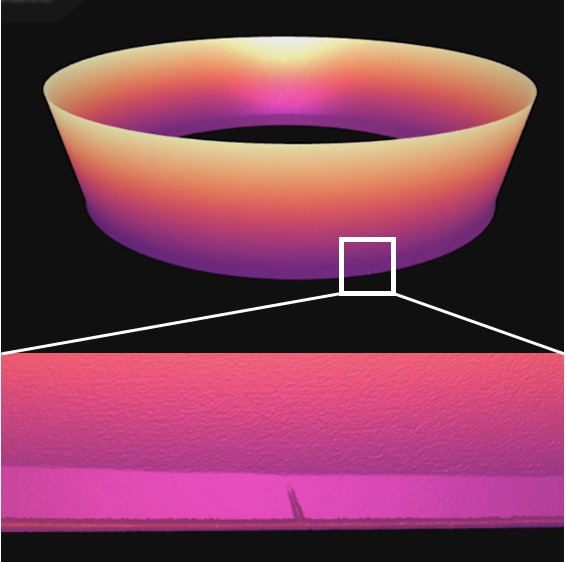

The presence of 3D microdefects can be highly detrimental to the smooth motion of a bearing. It is thus crucial to track and detect all defects that will affect the operation of the final bearing assembly, especially on the cylindrical surfaces of the bearing components. Because OptoComb 3D scanners have a coaxial configuration, setting up a 45° mirror along the OptoComb laser path in order to dive into the bearing structure and perform a visual inspection of internal walls. In this configuration, manufacturers can not only detect and identify 3D microdefects on such critical surfaces, but also quantify their size with a 2μm resolution. Manufacturers can leverage this quantitative information to fully engineer and optimize the fabrication process of their bearings.