High-accuracy 3D scanners for the dimensional inspection of complex parts

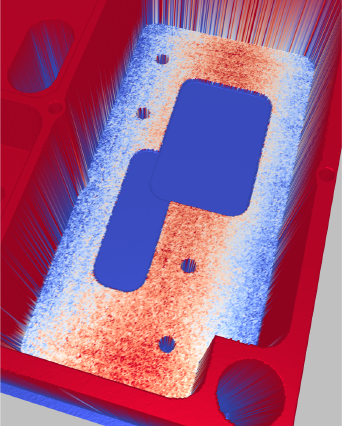

> Volume calculation

> Visual inspection

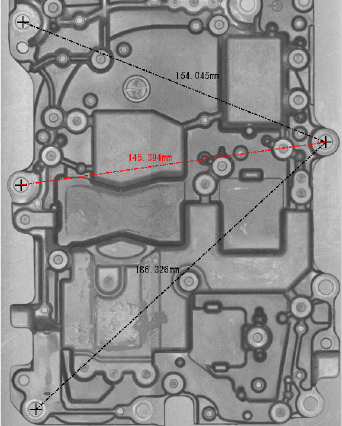

> Dimension measurement

> Dimensions of products are measured by hand and only sampling inspections can be performed.

> Volume cannot be calculated manually.

> Conduct a complete inspection.

> Geometric feature detection

> Bore to bore distance measurement

> Point-to-point/plane distance measurement

> Flatness calculation

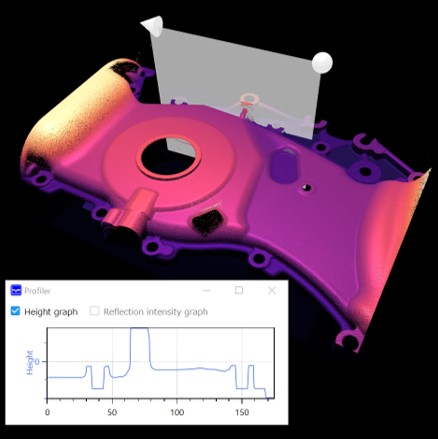

> Step assessment

> Automated inspection report generation

> Export your data and inspection reports

And more!

OptoComb's technology is based on optical frequency combs, coaxial laser systems that scan objects and give access to the full 3D profile of parts with high accuracy. With this technology, Optocomb 3D scanners are capable of measuring 500,000 data points per second, a high-speed performance that significantly shortens the time to scan manufactured parts. As a result, they are the ideal solution for a fully automated dimensional inspection of complex structures such as cast, forged, and machined parts. Breaking up with existing technologies, Optocomb 3D scanners thus represent a major breakthrough in the field of inspection.