Automated GD&T analysis and visual inspection of your conrod

resolution dimensional and visual inspection of the part. This high-speed, high-resolution performance allows for in-line quality control of every manufactured connecting rod without human intervention. Our OptoComb's measurement software "Optocomb Suite" allows you to fully integrate and automate the entire connecting rod inspection process, from component measurement to data processing and quality assessment.

> Dimension inspection and scratch inspection of connecting rod parts

> 100% inspection of manufacturing inline

・Manual visual inspection

- Large error in dimension measurement of complex shapes

・100% inspection on manufacturing inline

・Full 3D profile

・Fast & automated scanning

・User-friendly measurement and analysis

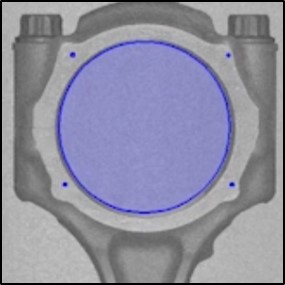

・Bore inspection

・Automated GD&T analysis

・Automated microdefect detection

・Automated inspection report generation

・Export your data and inspection reports

With their unique Optocomb technology, 3D scanners can fully profile conrods in a few seconds and perform a high-resolution dimensional and visual inspection of the part. With such a high-speed and high-resolution performance, you can perform an in-line quality control of all your manufactured conrods without human intervention. With our metrology software, the Optocomb Suite, the whole inspection process of the conrod can be fully integrated and automated from part measurement to data processing and quality assessment.

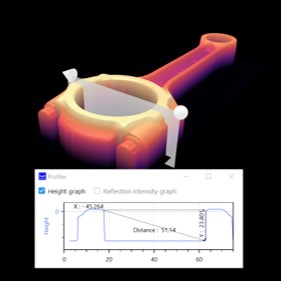

With the Optocomb Suite, you can for example automatically process your high-resolution Optocomb 3D data to automate the dimensional inspection of your connecting rod. You can generate your own custom recipe, automatically detect the conrod features, and instantly perform the quality control of the conrod: positional deviation, flatness, straightness, parallelism, diameter, roundness and more. The results of the dimensional inspection can then be instantly saved and leveraged to enhance and rationalize your manufacturing line.

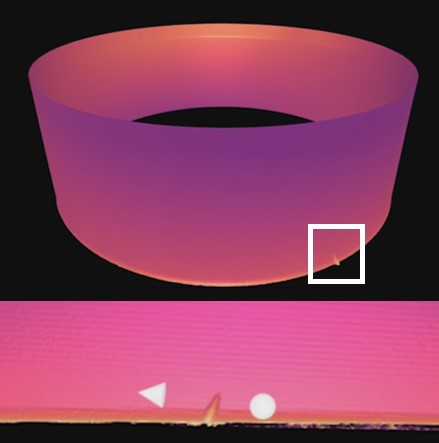

The presence of microdefects in the bores of connecting rod can be especially detrimental to the assembly process and the operation of the final product. But detecting such small defects in bores can be a daunting task for manufacturers. By combining our OptoComb 3D scanners wiht a rotating mirror, it is possible to dive deep into the conrod bores and perform the visual inspection of their inner walls with a resolution as good as 2μm. Manufacturers can thus detect and identify 3D microdefects, and extract their size in all three dimensions. With such quantitative information, manufacturers can fully engineer the fabrication process of their connecting rods and strengthen their production system.