SOFTWARE

・3D 表示

・外観寸法形状の自動解析

・複雑形状の容積計算

・自動欠陥検出

・使いやすい測定・解析のインターフェース

・検査レポートの自動出力

・データや検査レポートのエクスポート

・And more...

Software

View more

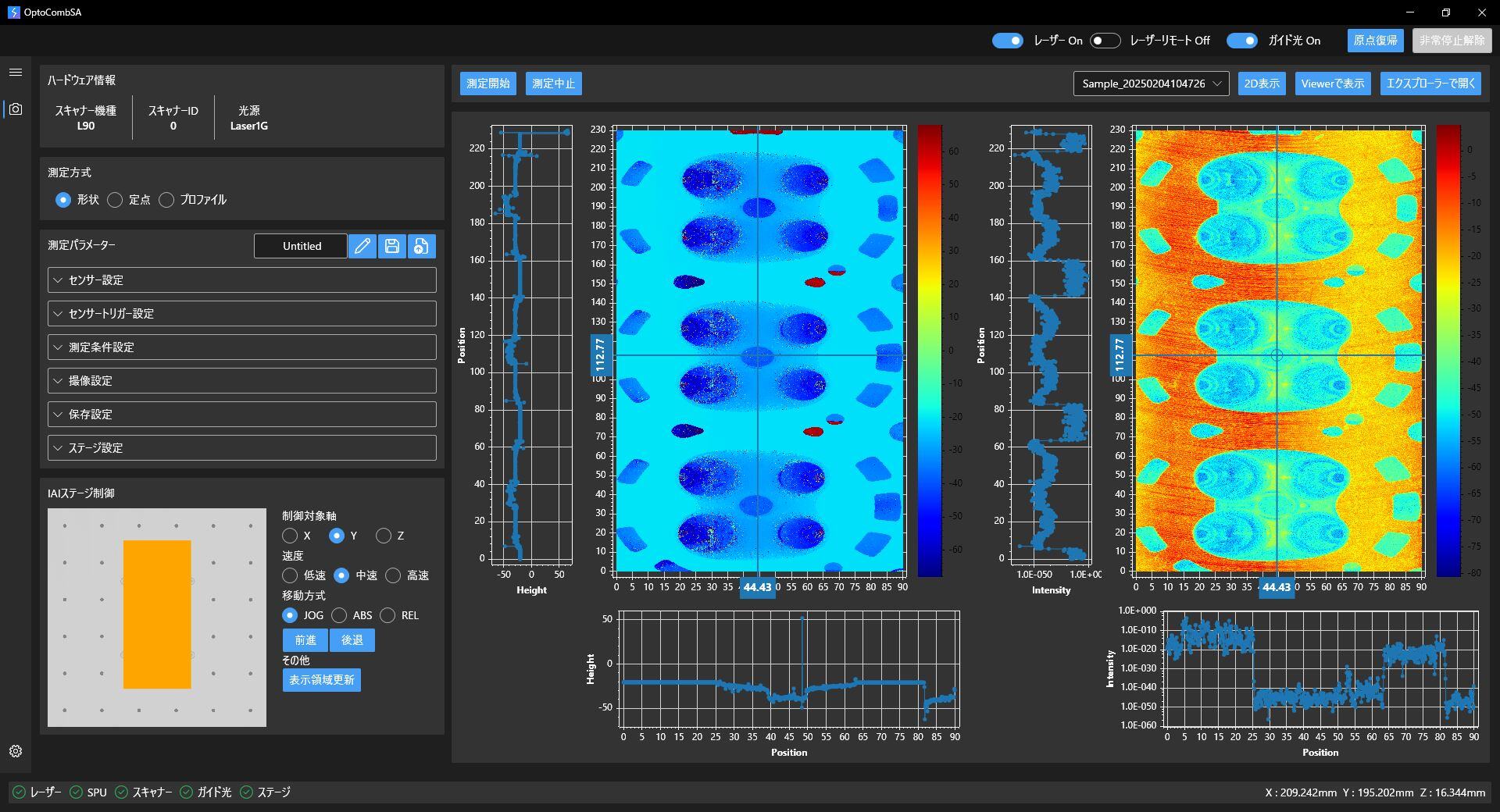

光コム3D点群データを取得するためのスキャンソフトです。

スキャンエリア、点間ピッチなどパラメータ設定が可能で、データ取得条件の最適化が容易に行えます。

主な機能

・光コム3D点群データ取得

OptoComb Viewer、Detector、Measureのライセンスをパッケージ化し、使いやすく仕上げました。

3D点群データの可視化から解析処理まで必要なライセンスを組み合わせることで、検査プロセスの自動化が容易になります。

主な機能

・Optocomb Viewer

・Optocomb Detector

・Optocomb Measure

光コムセンサーで取得した形状のXYZ点群データを容積換算し、スキャンエリアの容積を算出します。

これまでアナログで測定していた容積を非接触かつ自動検査が可能になるため、大幅な省人化と作業効率向上が実現します。検査レポートの自動生成までワンストップで行います。

主な機能

・容積検査

・外観寸法形状 自動解析

・カスタム検査レシピ

XYZポジションのシーケンスプログラムをベースにスキャンを行います。

事前にシーケンスを組むことでスキャンエリアを自由に組み合わせたスキャンが可能になります。

主な機能

・スキャンシーケンスの作成実行

お客様で検査ソフトウェアの構築や設備連携される場合には、現場ソフトウェア開発環境に合わせて開発キットをご提供します。

主な機能

・検査ソフトウェア開発キット

お客様の製造ラインにおいて光コムセンサを最適にお使いいただくためのカスタムソフトウェアです。

主な機能

・要求仕様に基づくカスタム設計