HARDWARE

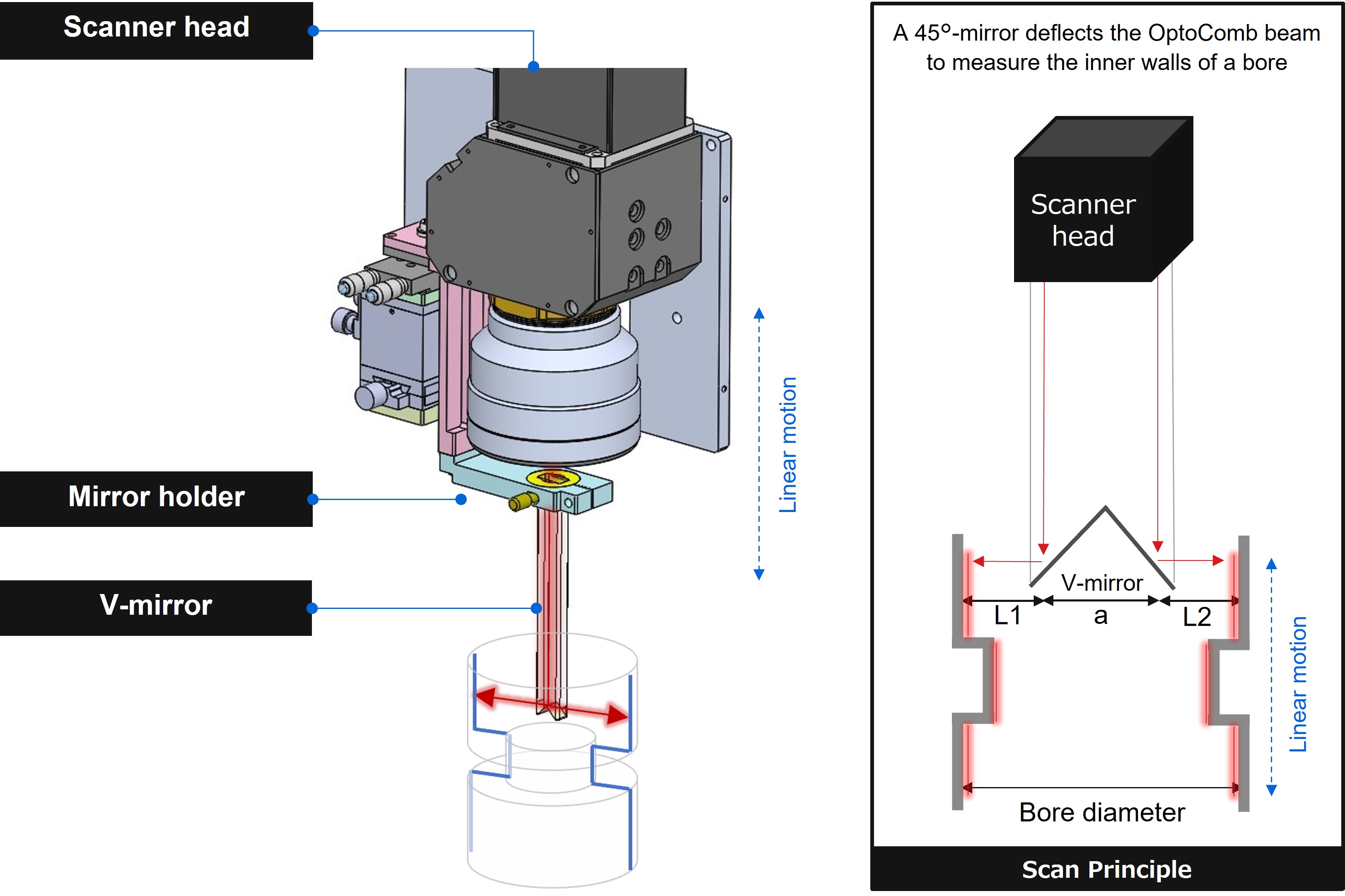

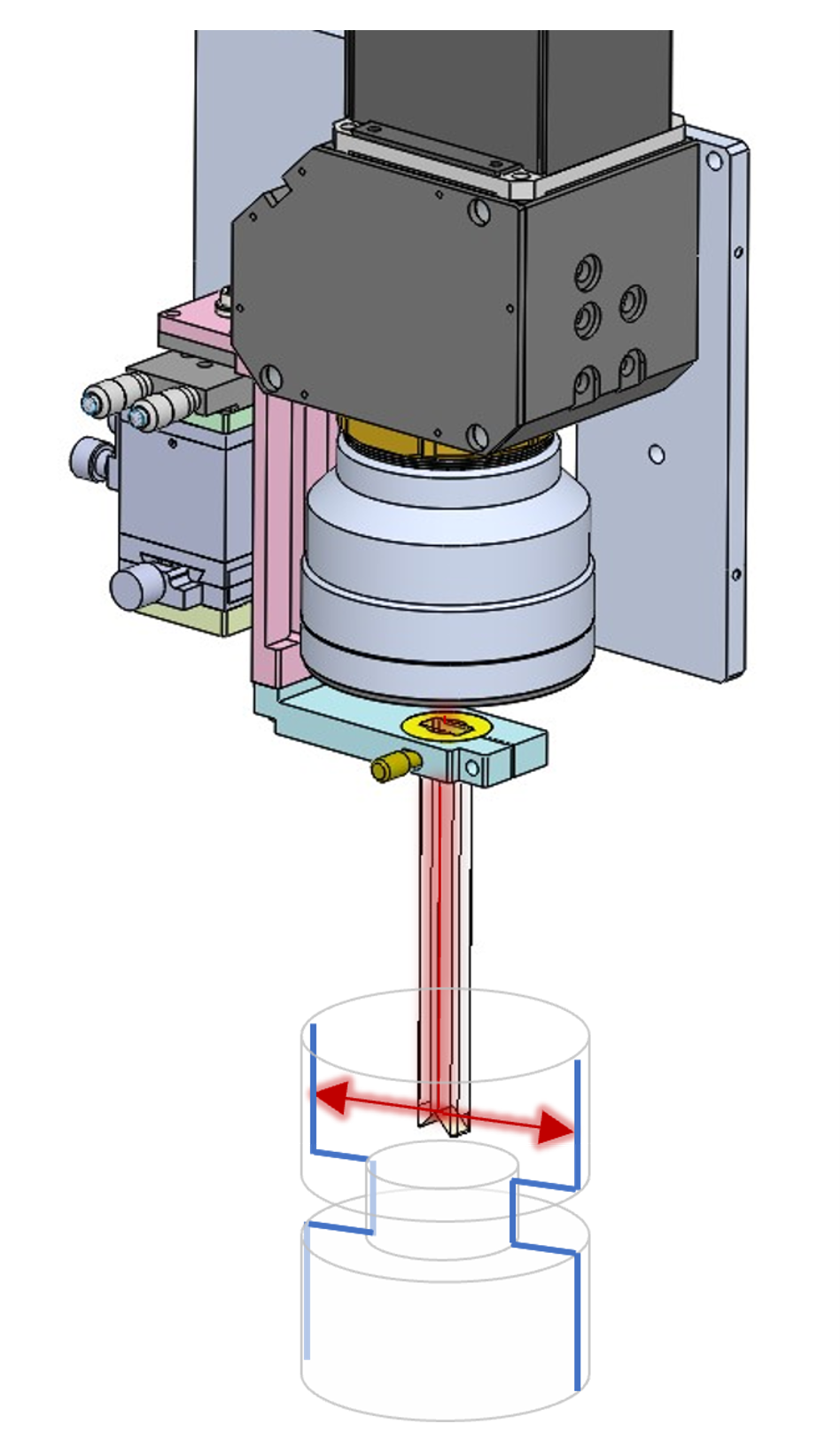

中型および大型の部品の多くは、深く複雑な構造を持っており、高度な品質要件と、最新の製造における要求の厳しい設計を満たす必要があります。 これまで、マイクロメートルの精度でこのような構造をインライン検査することは、とらえどころのないままでした。 マイクロメートルレベルの精度を提供しながら、円筒構造の奥深くにある寸法情報にアクセスすることは重要な課題であるため、ボアの場合は特にそうです。 独自の同軸構成と高精度を活用する OptoComb 3D センサを 45° ミラーと組み合わせて、この問題にうまく対処できます。

そこで我々は、OptoCombセンサと、構造内で z 軸に沿って平行移動する逆 V 字型ミラーを組み合わせた OptoComb V ミラー システムを開発しました。 このシステムにより、新しい寸法検査ソリューションをテーブルにもたらし、ボア、シリンダー、およびその他の複雑な構造の内壁を高精度でスキャンし、幅広い製造部品の GD&T 分析を可能にします。

Problem

View more

Function

View more

ボアや円筒部品の内壁、スリットの立壁、ケース…

マイクロスケールの精度で直径、真直度、位置に直接アクセスできます。

すべての OptoComb 3D スキャナー構成と互換性がある Vミラー オプションは、測定範囲と精度を検査仕様に適応させることができます。

Specification

View more

ダダミーテキストミーテキストダミーテキストダミーテキストダミーテキストダミーテキストダミーテキストダミーテキスト

Hardware

View more

OptoCombの光コム3次元センサーはノーベル賞技術「光コム」を世界で初めて産業応用し実現した製品です。同軸光学系での計測、長いワーキングディスタンス、500kHzでの高速なデータ取得、1μm の高さ分解能により自動検査に理想的な3次元検査ソリューションを提供します。インラインへの搭載で凹凸の大きな複雑形状に対する寸法検査・外観検査の自動化を可能とします。

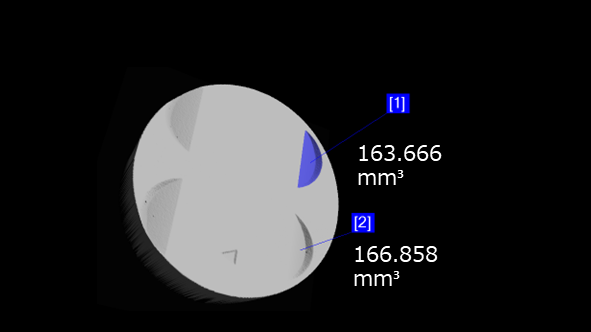

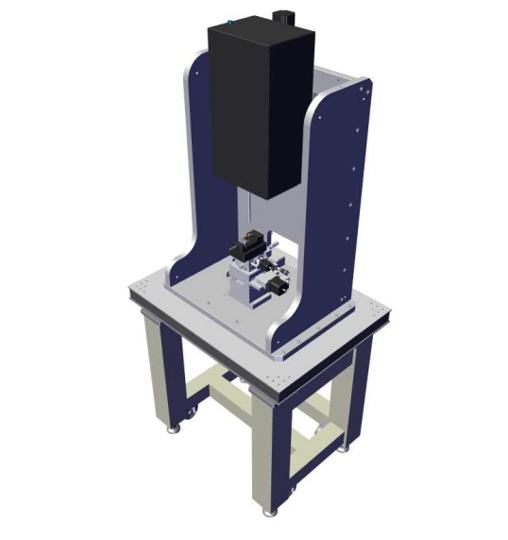

光コムレーザーを使った高速ヘリカルスキャンで部品内面の検査を高精度で可能にしました。既存の内面検査装置と異なり、1本のスピンドルで幅広い直径に対応。外観、形状、寸法を位置度の測定で自動検査が可能です。汎用的な卓上検査装置からインラインでの全数検査まで対応が可能です。

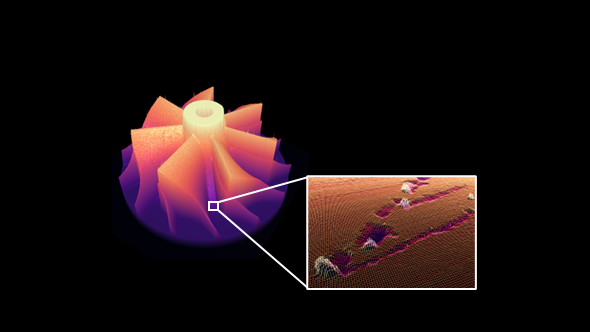

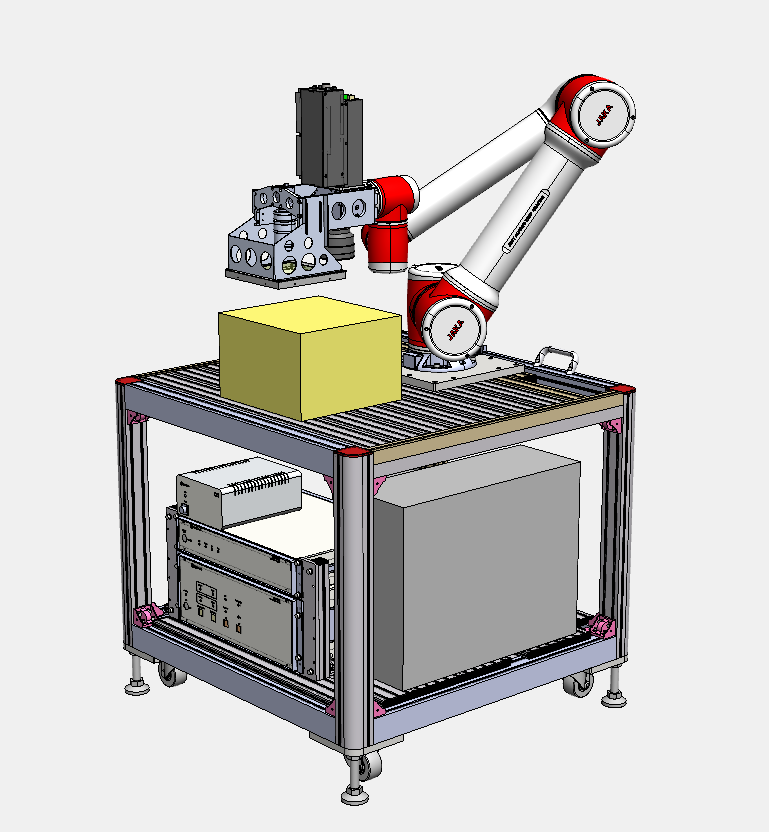

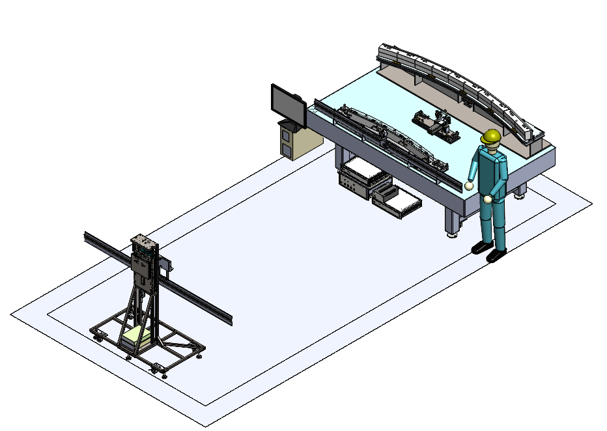

ロボットアームに画像カメラ、光コム3次元センサー、AIを搭載した自動外観検査の最上位ソリューションです。画像カメラ、AIによる欠陥候補の検出を高速に行い、欠陥候補を光コム3次元センサーで測定します。ロボットアームを活用することで大型複雑形状ワークの多面検査に対応します。

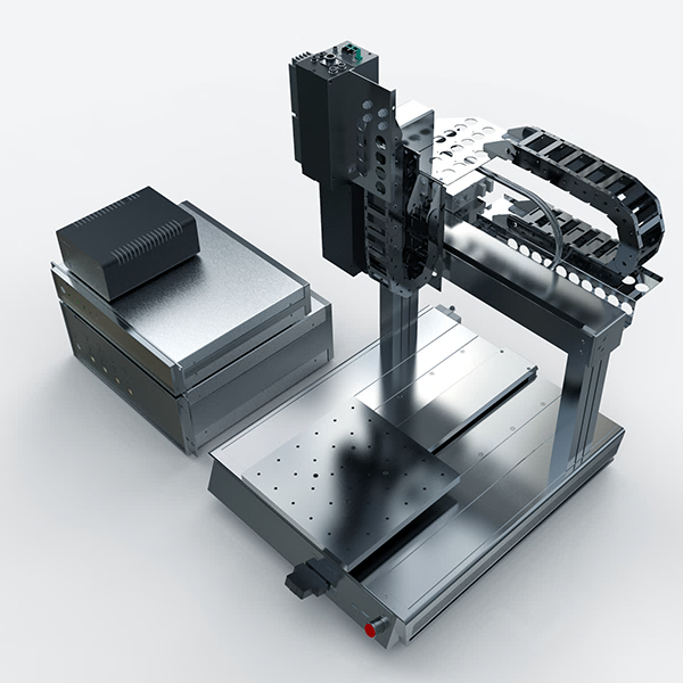

光コム3次元センサーを活用した3次元検査装置のベースモデルです。XYZのステージによってワーク上面を検査します。凹凸のある鋳造製品の加工面など複雑形状部品の外観、形状、寸法検査が1度の測定で可能です。小型ワークを複数並べての同時検査など幅広い用途で活用できます。

非接触完全同期のリアルタイム多点振動計。従来のスキャンニングや接触式では不可能な多点同時計測により、定常状態だけでなく過渡的な応答までリアルタイムに計測可能です。変位/速度/加速度/振動/周波数/モード解析など各種振動体の解析・検査に最適です。

複雑形状の光コムスキャン性能はそのままに、大型化・高速化を実現した新シリーズが登場しました。

470~2000mm幅まで一度にスキャン可能、かつ1秒間に125万点の高速測定により大型ワークの高精度形状計測、各種検査に最適です。

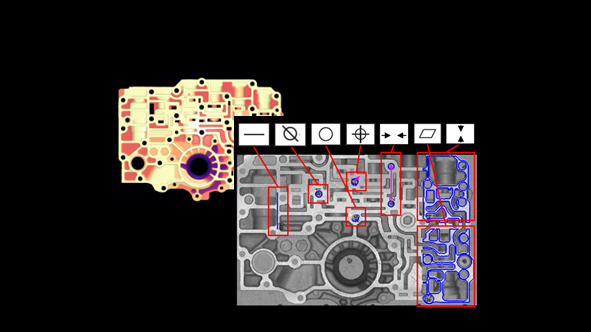

OptoComb SA(上面検査装置)に画像カメラ、AIを搭載したモデルです。画像カメラによる撮像、AIによる欠陥候補の検出を高速で行い、AIで検出した欠陥候補を光コム3次元センサーで測定。測定した箇所はルールベースで3次元定量化を行い、完全な3次元定量検査を高速に実行します。

OptoComb 360 は、光コム3次元センサーと回転ステージを組み合わせて対象物を 360° スキャンする独自の検査システムです。このシステムにより、OptoComb は新しい外観検査および寸法検査ソリューションを追加しました、回転対称性を持つスプールやその他の構造の外面を高精度で測定できます。

光コム3次元センサーと 45° ミラーと組み合わせ、高精度測定と独自の同軸構成を活用し 、穴の内壁や複雑な円筒構造を数秒で検査できます。

光コム発生器は光コムレーザーを発生させる装置です。研究用途などで光コムレーザーそのものを活用したい場合に最適です。温調付きのため周囲温度に左右されずに安定した光コムレーザーをお使いいただけます。