光コム発生器

光コム発生器は光コムレーザーを発生させるモジュールです。完全パッシブ型のため、非常に安定した光コムを発生します。

研究用途などで光コムレーザーそのものを活用したい場合に最適です。光コムモジュール単体と温調付きの2モデルからご選択いただけます。

Catalog

光コム発生器は光コムレーザーを発生させるモジュールです。完全パッシブ型のため、非常に安定した光コムを発生します。

研究用途などで光コムレーザーそのものを活用したい場合に最適です。光コムモジュール単体と温調付きの2モデルからご選択いただけます。

OptoCombソリューション、製品の総合カタログです。

高速ヘリカルスキャン測定による内面検査装置

光コムレーザーによる高精度な3次元測定によって外観と寸法と形状が同時に自動検査できます。

画像カメラ×光コム3次元レーザー×AI×ルールベースによる全数自動外観検査の完成形

画像カメラ、光コム3次元センサー、AI、ルールベースの良いとこ取りで高速に3次元全数自動検査を実現

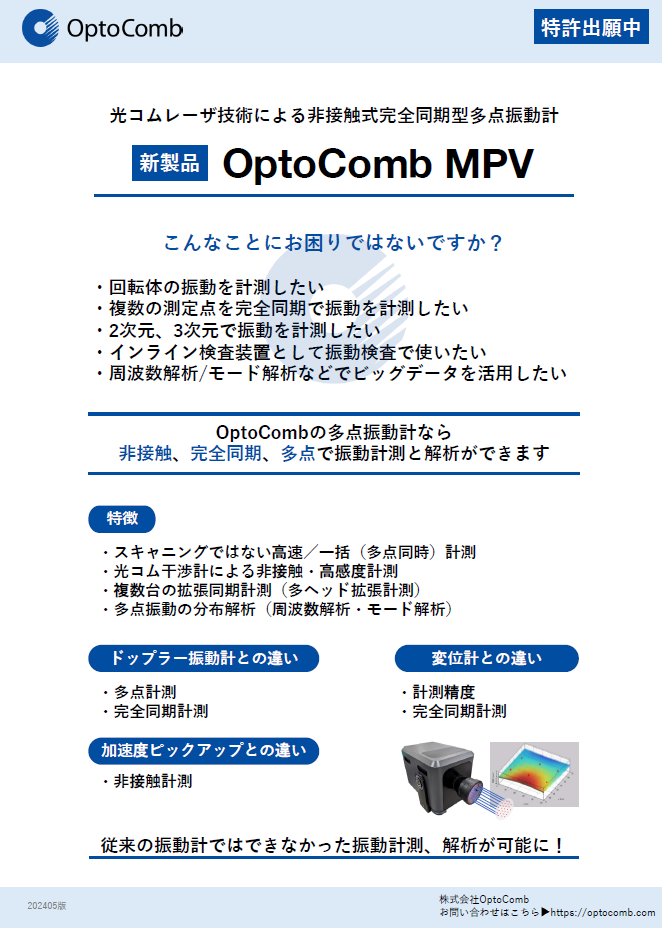

従来のスキャンニングや接触式では不可能な多点同時計測により、定常状態だけでなく過渡的な応答までリアルタイムに計測可能です。

変位/速度/加速度/振動/周波数/モード解析など各種振動体の解析・検査に最適です。

OptoCombの大型光コム3次元センサXLシリーズなら470~2000mm幅まで一度にスキャン可能です。

同時に高速化にも対応し、1秒間に125万点(弊社従来比2.25倍)の高速測定で大型ワークを測定します。

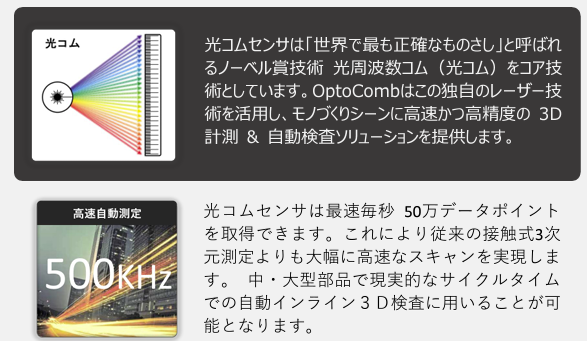

OptoCombセンサは 「 世界で最も正確なものさし 」と呼ばれ るノーベル賞技術 光周波数コム 光コム をコア技術としています 。 OptoComb はこの独自のレーザー技術を活用し 、 モノづくりシーンに高速かつ高精度の 3 D 計 Quality 4 0 ソリューションを提供します 。 OptoCombセンサは最速毎秒 50 万データポイントを取得できます 。 これにより従来の接触式 3 次元測定よりも大幅に高速なスキャンを実現します。中 ・ 大型部品で現実的な…

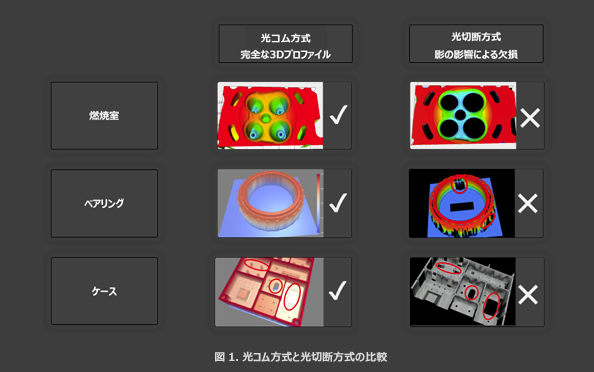

OptoCombの光コム技術を用いた3次元計測は、同軸光学系での計測であるため、物体全面で遮られることのない完全な3次元プロファイルを、高い精度で得ることができます。 OptoCombの光コムセンサ L90(広範囲モデル)とS40(高精細モデル)では、最速で毎秒500,000 データポイントを取得することができ、この高速性により接触式と比較して部品をスキャンする時間は大幅に短縮されます。 …

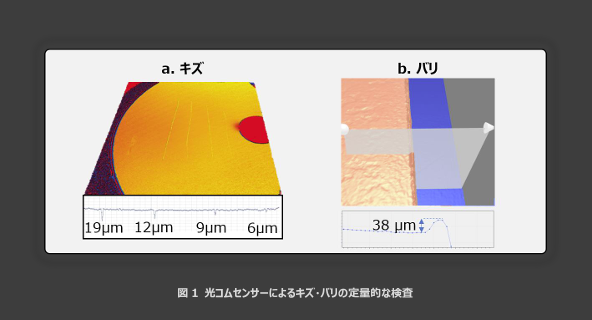

エンジニアリングでは、定量的な判断が必要とされ、可能であるべきですが、人による検査に依存している製造現場では、定量評価自体が多くの場合困難です。OptoCombが提供する自動検査ソリューションは、数~数十ミクロンレベルの欠陥の定量的検査を可能します。 OptoCombのS40、M5センサーは、凹み、キズ、異物、バリなどの広範囲な3次元欠陥を検出することについて、信頼性の高い実績があります。3次元欠陥の定量的な情報を用いる…

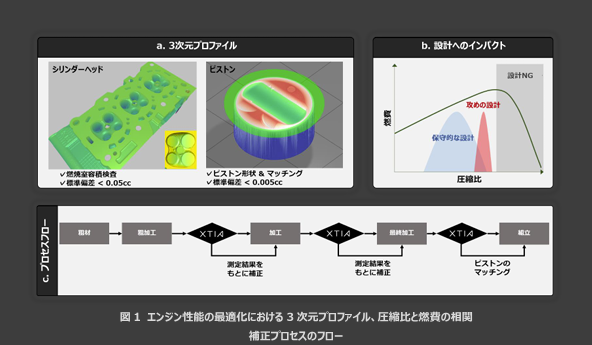

OptoCombの光コム技術を用いた同軸光学系の3次元計測は、複雑形状の部品においても、高い精度で死角のない3次元プロファイルを得ることができます。そのため、製造プロセスのフローの途中にこの3次元計測を導入すると、その情報をもとに補正加工を実施することができ、設計における幾何公差の低減が可能となります。このOptoCombのソリューションが大きな付加価値を生み出します。 幾何公差とは製造プロセスの能力を考慮した許容できる…

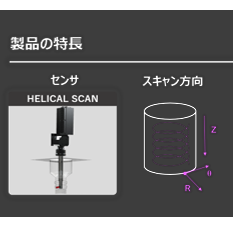

中・大型部品の中には円筒形状が含まれることが多く、その形状は高い品質と現代のモノづくりが求める加工精度を満たす必要があります。例えば、シリンダーブロック(図1)は、ピストンが上下するシリンダー部分をもったエンジンの重要な部品です。そのシリンダー部分の寸法とその内面に欠陥があるかどうかは、エンジンの性能にとって非常に重要です。 従来は、このような円筒の内面をミクロンオーダーの精度で、インライン3D検査はできないとされてきました。…

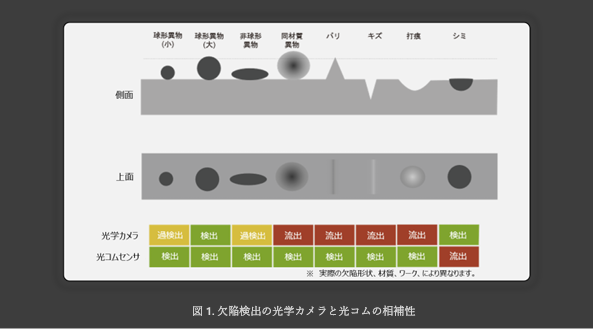

自動検査の汎用化が非常に難しい理由は、検査すべき欠陥が多種多様であり1種類のセンサでそれらすべてを検出することが事実上不可能であるためです。逆に、さまざまな種類の欠陥に対してそれぞれ適切なセンサを用いようとすると時間とコストがかかり、その結果、検査プロセスを自動化する上での大きな障壁になります。光学コムセンサは非常に多彩な3次元欠陥を検出できますが、光学カメラを用いると検出機能を補完することができます。…

自動車産業をはじめとする日本の多くのものづくりは、突き抜けた製造現場力に支えられています。世界では、製造現場の在り方としてドイツでインダストリー4.0が提言され、工場の自動化、合理化を目指した「考える工場」が世界的に注目が集まっている中、実は日本ではいち早く、現場の自動化に動いていました。製造の現場力を究極に高めてきたモノづくりの国、日本だからこそ、人によるオペレーションの限界に早期に…