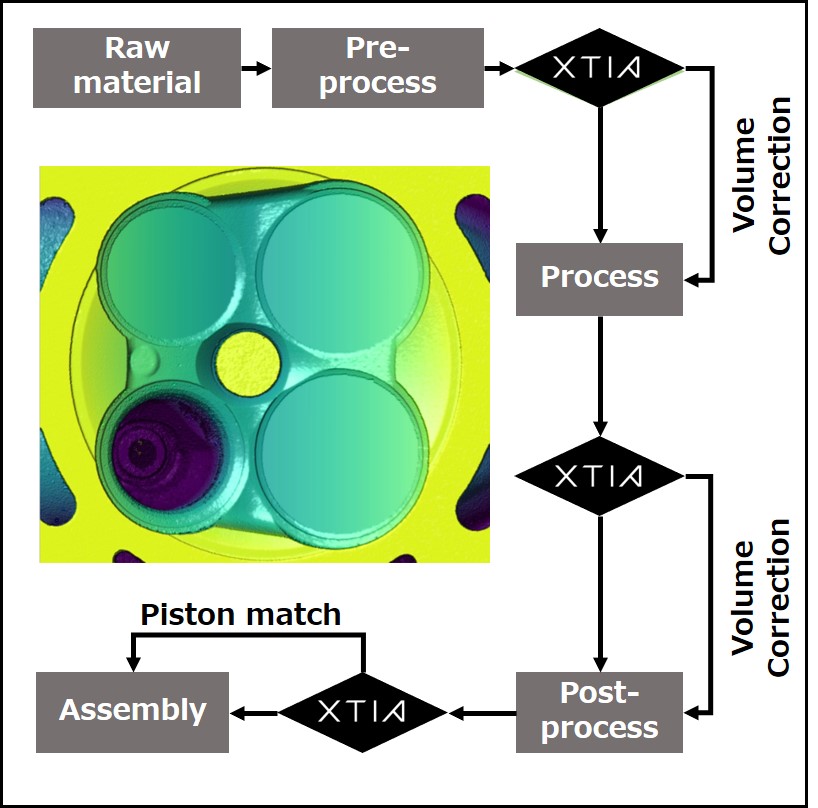

私達の光コム技術を用いた同軸光学系の 3次元計測は、複雑形状の部品においても、高い精度で死角のない 3次元プロファイルを得ることができます。そのため、製造プロセスのフローの途中にこの 3次元計測を導入すると、その情報をもとに補正加工を実施することができ、設計における幾何公差の低減が可能となります。この ソフトウェアソリューションが大きな付加価値を生み出します。

・シリンダーブロックの容積が設計どおりか測定したい。

・幾何公差の低減

・容積計算を高精度で実現するソリューションが見つからなかった。

・全数検査の実現

・シリンダーヘッドの全数自動3D計測、チャンバー容積の容積値を高精度で算出

・結果をもとにした補正加工が可能とする「攻めの設計」で燃費向上を実現

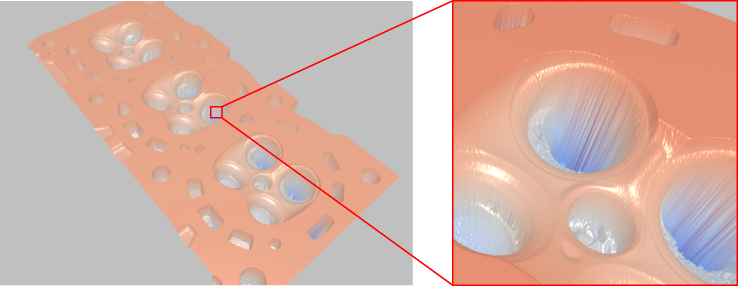

光コム技術を用いた同軸光学系の 3次元計測は、複雑形状の部品においても、高い精度で死角のない 3次元プロファイルを得ることができます。そのため、製造プロセスのフローの途中にこの 3次元計測を導入すると、その情報をもとに補正加工を実施することができ、設計における幾何公差の低減が可能となります。我々のソリューションが大きな付加価値を生み出します。

この補正加工の事例として自動車の燃費をつかさどる部品であるシリンダーヘッドの検査にて高い実績を誇りますので、それを例に説明します。

内燃機関では、ピストンがこのシリンダー内を上下します。そのピストンが動く空間の体積が排気量となります。そして、シリンダー内が最も圧縮された状態にあるときの体積が燃焼室容積です。圧縮比は(燃焼室容積+排気量)÷(燃焼室容積)という計算式になります。シリンダーヘッドにおいて、チャンバー部位の燃焼室容積は車の燃費においてキーとなる部位となります。この圧縮比を高めていくことにより車の燃費は良くなっていきます。しかし、圧縮比を上げすぎると、ノッキングなどの信頼性問題となりいかに信頼性問題に差し掛からないところまで圧縮比をあげるかが燃費を上げるうえでのキーポイントとなります。ここで、燃焼室にあたるシリンダーヘッドのチャンバー容積のばらつきが大きいと信頼性問題を回避するために安全な縮比の設計にする必要があり、車の燃費は悪化します。そこで、シリンダーヘッドを加工後にチャンバー容積を全数検査行い容積の数字をしることができれば、その後に補正加工にてばらつきを削減することが可能となり、より攻めた設計値を追い込むことで車の燃費を上げることが可能となります。このシリンダーヘッドという複雑性を有した部品を高い精度で高速に全数検査できるのが光コム技術を用いた我々のソリューションとなります。加工→検査→補正加工というプロセスフローを組むことにより高い精度にて補正加工を実現することができます。その容積のばらつきを標準偏差にて0.01cc以下で達成することができました。

このように、加工と我々の3Dセンサーを組み合わせることにて今までにない高い付加価値を創出することを可能とします。