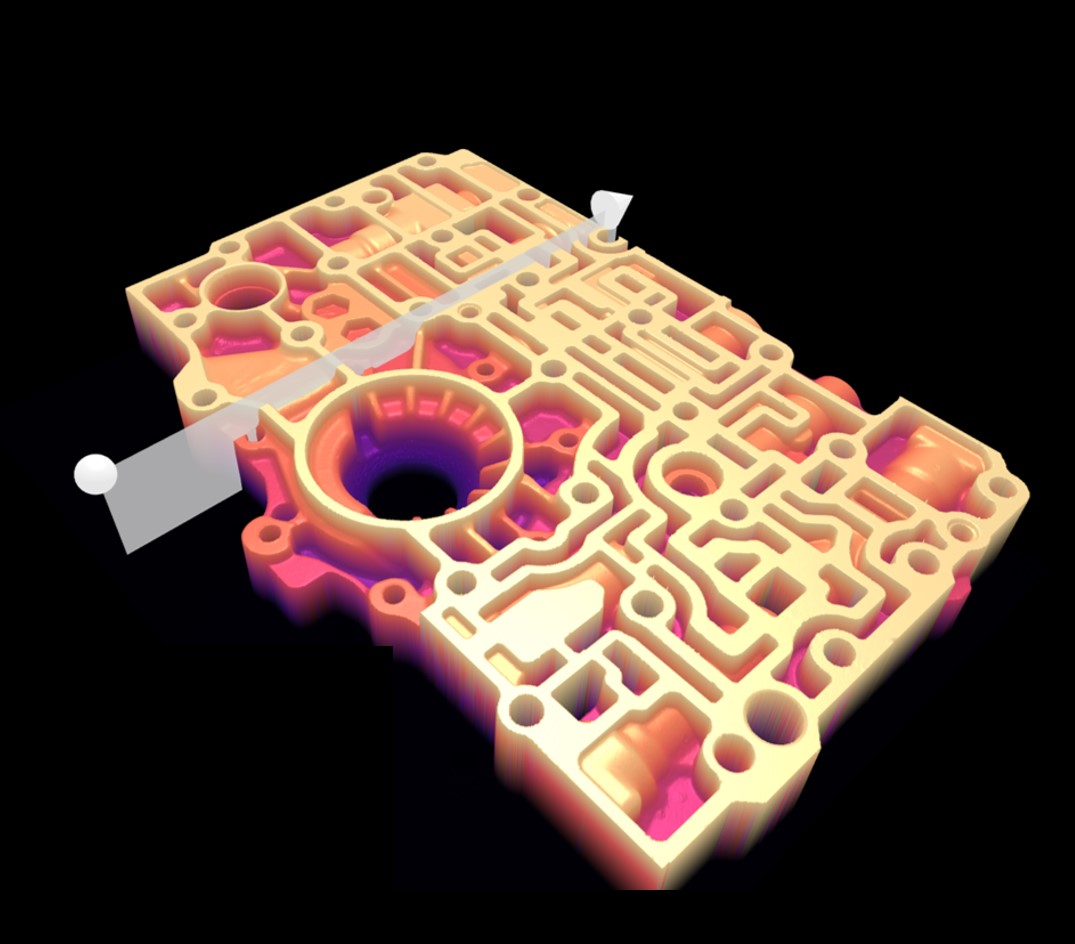

バルブボディのような複雑な部品の検査工程の自動化は製造業にとって難しい仕事です。なぜならば従来の方法では時間がかかったり、全体の3Dプロファイルを得ることができなかったりするためです。同軸構造で長いワーキングディスタンスを持つXTIAの光コム3Dスキャナーはそのような困難を乗り越え、影の影響を受けることなくバルブボディの小さな形状や欠陥を得ることができます。ユーザーは当社の3Dスキャナーが持つ1秒間に50万点のスキャン速度によってバルブボディの品質管理を完全に自動化でき、マイクロメートルオーダーの分解能でインラインの外観・寸法検査を実行できます。

・説明のテキストが入ります。・説明のテキストが入ります。

・説明のテキストが入ります。・説明のテキストが入ります。

・説明のテキストが入ります。・説明のテキストが入ります。

・説明のテキストが入ります。・説明のテキストが入ります。

・説明のテキストが入ります。・説明のテキストが入ります。

・説明のテキストが入ります。・説明のテキストが入ります。

・1スキャンでの全体の3D プロファイル

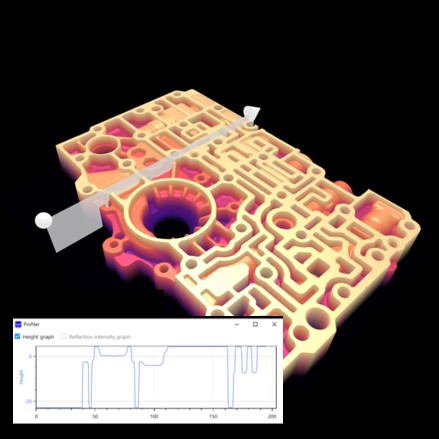

・高速・自動測定

・ユーザーフレンドリーな計測と解析

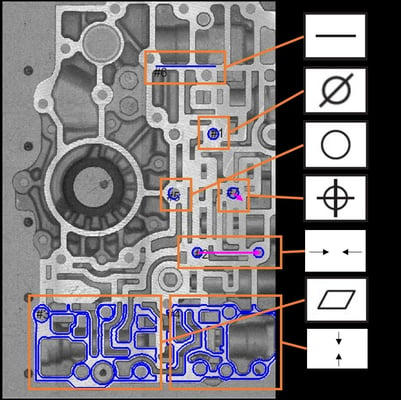

・自動での寸法幾何公差解析

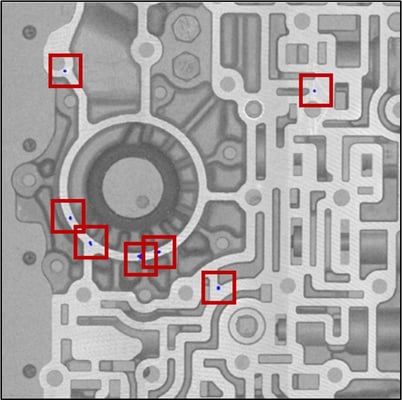

・自動での微小欠陥検出

・自動での検査レポート生成

・データと検査レポートの出力が可能

バルブボディのような複雑な部品の検査工程の自動化は製造業にとって難しい仕事です。なぜならば従来の方法では時間がかかったり、全体の3Dプロファイルを得ることができなかったりするためです。同軸構造で長いワーキングディスタンスを持つXTIAの光コム3Dスキャナーはそのような困難を乗り越え、影の影響を受けることなくバルブボディの小さな形状や欠陥を得ることができます。ユーザーは当社の3Dスキャナーが持つ1秒間に50万点のスキャン速度によってバルブボディの品質管理を完全に自動化でき、マイクロメートルオーダーの分解能でインラインの外観・寸法検査を実行できます。

XTIAの汎用計測ソフトウェア「Optocomb Suite」はバルブボディの測定から3Dデータ処理、自動寸法幾何公差解析まで検査プロセスを統合できます。特にOptocomb Suiteの1ツールボックスであるOptocomb Rulerはカスタマイズした検査レシピを作ることができ、測定プロセスと並行して寸法検査を実行できます。自動的に部品の形状を認識し、高分解能でバルブボディのすべての公差(位置度、直径、真円度、平面度、真直度、平行度など)を取得します。

光コムスキャナー L90を用いれば、1スキャンでバルブボディの寸法検査だけでなく、凹みやキズ、鋳巣のような数百マイクロメートル欠陥を検出することができます。微小なキズやバリ、異物のようなより小さな欠陥は高分解能タイプのS40や超高分解能タイプのM5で検査することができます。高分解能な3Dデータをもとに、Optocomb Suiteの1ツールボックスであるOptocomb Detectorを用いて、自動的に三次元で欠陥の検出・判定し、欠陥サイズを定量することができます。ユーザーは定量的な情報によってバルブボディの製造工程を管理し、製造ラインを最適化することができます。