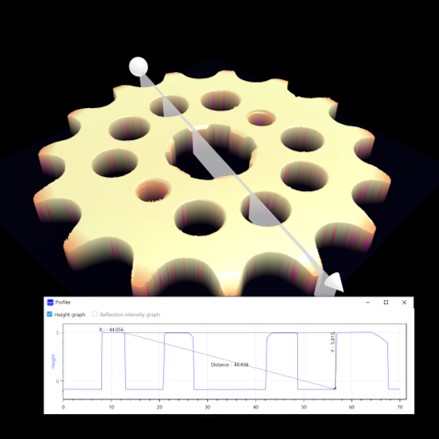

製造業では現代において高い品質要求と非常に厳しい設計に対して高速かつ正確な計測方法が必要とされています。これは厳しい公差と短い検査時間を求められやすいスプロケットでは特に当てはまります。XTIAの光コム3Dスキャナーを用いることで、ユーザーは1秒間に50万点の速度でインライン計測し、1μm程度の分解能でスプロケット全体のプロファイルを得ることができます。光コム3Dスキャナーをインラインに組み込むことで、1度で外観・寸法検査の両方を実行でき、製造されたスプロケットのすべての検査を自動化できます。

・説明のテキストが入ります。・説明のテキストが入ります。

・説明のテキストが入ります。・説明のテキストが入ります。

・説明のテキストが入ります。・説明のテキストが入ります。

・説明のテキストが入ります。・説明のテキストが入ります。

・説明のテキストが入ります。・説明のテキストが入ります。

・説明のテキストが入ります。・説明のテキストが入ります。

・1回の測定で全体の3Dプロファイルが取得可能

・1 μmの分解能

・高速&自動スキャン

・ユーザーフレンドリーな計測と解析

・微小欠陥の自動検出

・自動検査レポート作成

・データや検査報告書の出力

製造業では現代において高い品質要求と非常に厳しい設計に対して高速かつ正確な計測方法が必要とされています。これは厳しい公差と短い検査時間を求められやすいスプロケットでは特に当てはまります。XTIAの光コム3Dスキャナーを用いることで、ユーザーは1秒間に50万点の速度でインライン計測し、1μm程度の分解能でスプロケット全体のプロファイルを得ることができます。光コム3Dスキャナーをインラインに組み込むことで、1度で外観・寸法検査の両方を実行でき、製造されたスプロケットのすべての検査を自動化できます。

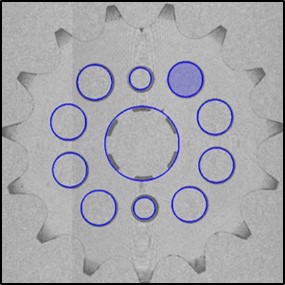

XTIAは3Dスキャンのみならずデータ処理から部品の評価までスプロケットの検査プロセスを完全自動化するためのソリューションを提供しています。XTIAの計測ソフトウェア「Optocomb Suite」を用いれば、測定内容に合わせた寸法検査レシピを作ることができます。3Dデータ処理をシームレスに実行し、部品のすべての寸法・幾何公差測定に活用できます。Optocomb Suiteはスプロケットのすべての公差(穴径、穴位置度、平面度など)の高精度測定を可能にします。ユーザーは品質管理プロセスの改善へつながり、製造システムを最適化するためのデータを活用することができるようになります。

高分解能な光コムの3Dデータが使えるのは寸法検査だけではありません。スプロケットの外観検査でも優れた力を発揮します。光コムスキャナーを用いることで、凹みやキズ、バリのような微小な三次元の欠陥を検出することができます。Optocomb Suiteはパワフルな欠陥検出アルゴリズムによって外観検査プロセスを自動化し、微小欠陥のサイズを三次元で正確に表現できます。製造ラインにおいては、微小欠陥の正確な三次元情報という価値の高い情報は、定量的な情報で支えられた信頼できる品質管理工程を創るための鍵といえるでしょう。