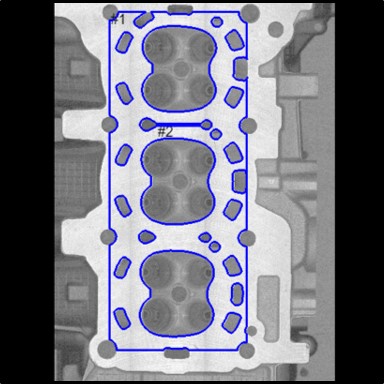

ノーベル賞技術「光コム」を用いたXTIA独自の 3Dスキャナでは、ミクロンオーダーの精度でシリンダーヘッドの全面プロファイルを得ることができます。1回のスキャンデータから寸法検査と外観検査の両方を行うことができます。光コム 3Dスキャナは、1秒間に50万点のデータ取得が可能で、細かいデータ取得間隔でもシリンダーヘッドのフルスキャンを数十秒で完了することができます。従来の接触型三次元測定機による検査方法に比べて格段に高速であるだけでなく、測定レシピが不要なため、柔軟で使い勝手の良い検査が可能です。

・燃焼室の容積の測定

・全数検査

・複雑形状の検査で奥まった部分に検査装置が届かない。

・加工後の容積が知りたい。

・シリンダーヘッドの全面の3Dプロファイル取得

・接触式3次元測定機と比較して圧倒的な短時間

・ユーザーフレンドリーな測定と解析

・燃焼室の容積計算アルゴリズム

・自動寸法検査

・自動欠陥検出

・検査レポート作成を自動化可能

・3Dデータ、検査レポートの出力

ノーベル賞技術「光コム」を用いたXTIA独自の 3Dスキャナでは、ミクロンオーダーの精度でシリンダーヘッドの全面プロファイルを得ることができます。1回のスキャンデータから寸法検査と外観検査の両方を行うことができます。光コム 3Dスキャナは、1秒間に50万点のデータ取得が可能で、細かいデータ取得間隔でもシリンダーヘッドのフルスキャンを数十秒で完了することができます。従来の接触型三次元測定機による検査方法に比べて格段に高速であるだけでなく、測定レシピが不要なため、柔軟で使い勝手の良い検査が可能です。

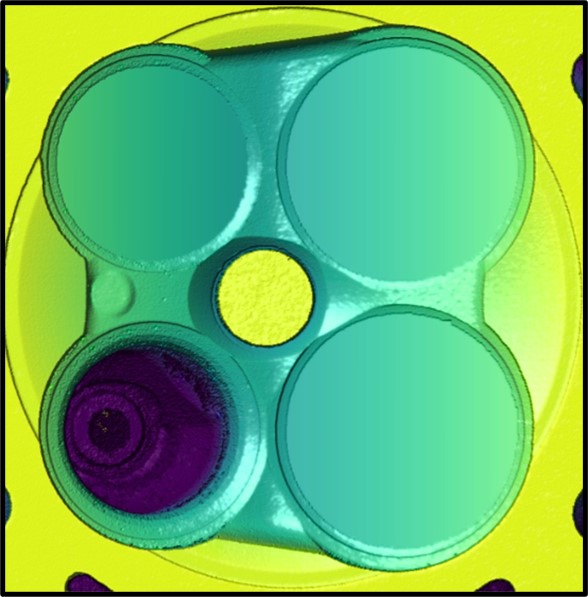

光コム3Dスキャナは、その同軸設計と長いワーキングディスタンスにより、燃焼室の完全な3Dプロファイルの測定に最適です。私達の包括的な計測ソフトウェアであるOptocomb Suiteは、このデータを処理して各チャンバーの容積を高精度に算出します。広範囲モデルL90 スキャナを用いた容積測定を活用しシリンダーヘッド製造プロセスを最適化、燃焼室の容積のばらつきを0.01cc以下に抑え、エンジン性能の向上に貢献しています。

Optocomb Suiteでは、高解像度の光コム 3Dデータを自動処理し、シリンダーヘッドの寸法検査を自動化することもできます。検査に合わせてユーザーがレシピを作成することができ、そのレシピに基づいてソフトウェアがシリンダーヘッドの形状を自動的に検出し、部品のすべての幾何寸法・公差(直径、位置ずれ、平坦度、真直度、平行度、真円度など)を即座に評価します。シリンダーヘッドの寸法検査の結果は簡単にエクスポートでき、品質管理システムに接続することができます。

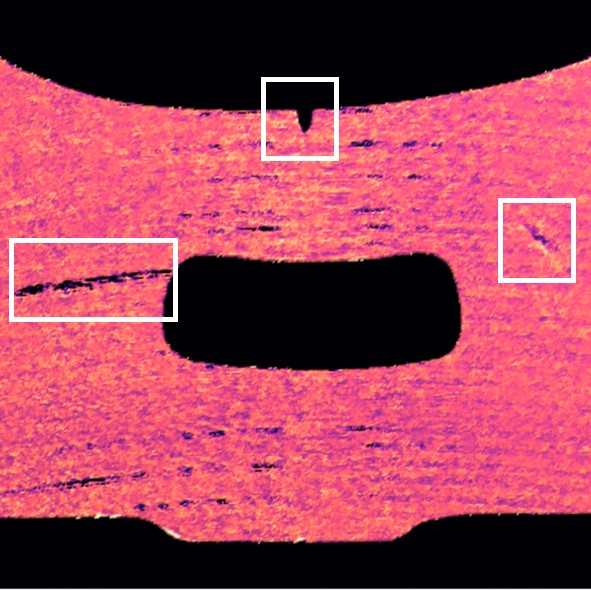

1回のスキャンで、シリンダーヘッドの寸法検査と同時に外観検査を行うこともできます。らOptoComb L90スキャナーを使えば、10umのz解像度でシリンダーヘッドの表面仕上げを評価することができます。研磨欠陥、へこみ、異物を識別し、定量化することができます。当社の高解像度スキャナS40とM5は、さらに1ミクロンの解像度を達成し、バリやキズなどのより小さな3D微小欠陥の自動検査を実現します。